M12 Heatsink does not fit PCB Smart Effector Hole

-

I have a problem with the SmartEffector kit I have just bought from E3D reseller. The hole in the PCB is not exactly 12 mm diameter but rather around 11.8mm. As a result of this, the M12 thread of the heatsink has a very tight fit into the hole. and the heatsink does not rest where I believe it should be (marked in YELLOW), but in a small shoulder after the thread (marked in GREEN) and in a zone just a hair breadth wide. What can be done? I am afraid that any attempt of enlarging the hole might damage the piezo sensorIMG_0851.mp4

-

Yes it should rest on the flange as you have shown in yellow. Does the shoulder of the heatsink above that flange measure exactly 12.0mm ?

-

@dc42 Yes, the shoulder marked in green has an exact diameter of 12mm. It is the hole on the pcb which is a bit smaller, around 11.8 or 11.9. Should I enlarge it?

In fact I have another M12 threaded heatsink from another project and it happens the same. The shoulder is bigger than the hole

-

@dc42 I have had this same issue, heatsink on size and pcb hole slightly small. With mine the issue was not as pronounced and I was able to push the heatsink in for a very snug fit. I bought that smart effector a good while ago though.

-

@ignacmc the fit is designed to be very snug to avoid centering issues etc.

I just measured a couple of heatsinks i have to hand and they are 11.95 in diameter so it may be that the heatsinks are very lightly wider then they used to be at 12mm.

Can you screw the heatsink through the PCB?

-

@t3p3tony The screw passes through the hole quite snugly...but the shoulder below the screw is unable to pass. As I told you before, I have an old M12 threaded E3dv6 clone heatsink bought on aliexpress two years ago and it has exactly the same problem. Seems that the "excepcionality" is in the PCB hole diameter....

Should i enlarge the hole a bit by carefully sanding the inside or what would you suggest? Trying to push the shoulder by hand force through the hole has not been successful.

-

@ignacmc Ahh i see. i would try sanding rather than focring it through, especially as its only 0.1mm or so.

-

@t3p3tony Seems that the PCB is quite traslucid on that zone (up to 2mm around the hole....There should be not PCB tracks there that I could damage, right?

-

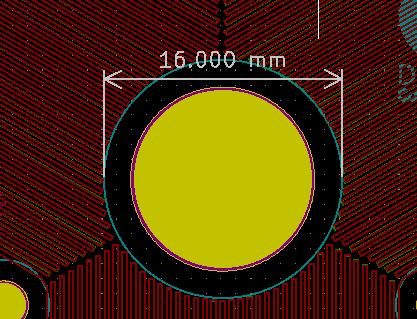

@ignacmc thats correct there is a 16mm diameter exclusion area:

-

@ignacmc, the PCB is only 2-layer and the traces are a few mm from the inside of the hole, so you can use e.g. a needle file to enlarge the hole slightly. But take great care not to scratch the fine strain gauge traces on either side of the PCB.

-

@dc42 I have just introduced my finger sheated with a piece of sandpaper, rubbed all around several times, and it seems to pass through now. I would say that I have not caused any noticeable "lateral play" or gap on the system...the fit is still snug so I expect it will work.

-

@ignacmc One last question...if I want to use a "non-threaded" heatsink like the Mosquito or Dragon Hotend....Will it work with a M12 printed adapter? there are some on Thingiverse

-

@ignacmc said in M12 Heatsink does not fit PCB Smart Effector Hole:

@ignacmc One last question...if I want to use a "non-threaded" heatsink like the Mosquito or Dragon Hotend....Will it work with a M12 printed adapter? there are some on Thingiverse

I don't see why that wouldn't work. A harder plastic will transmit the force of nozzle contact better than a soft plastic.

-

@ignacmc said in M12 Heatsink does not fit PCB Smart Effector Hole:

@ignacmc One last question...if I want to use a "non-threaded" heatsink like the Mosquito or Dragon Hotend....Will it work with a M12 printed adapter? there are some on Thingiverse

713maker do manufacture an adaptor for the Mosquito which IMHO would be the best option see https://713maker.com/gb/mosquito/mosquito-hot-end-duet-smart-effector-adaptor

hth

Doug