Diagonal rod length on delta printer issues.

-

Wow, reading that page, the comments there, the E3D dozuki pages on the topic of belts/pulleys and 2GT vs GT2... well... I hate to say this, but it has seriously lowered my opinion of E3D.

E3D has been asked numerous times if the products they list are GT2 or 2GT (which are not compatible with each other). They won't give a straight answer. They apologize for mis-listing one as the other, but still won't say which is which.

GT2 is made by Gates USA.

2GT is made by Gates Unitta in Asia.Supposedly both parts of the parent Gates company. But absolutely clear that the two profiles are not compatible.

Further, E3D now has a bunch of drawings that purport to be Gates 2GT, but are actually drawn by E3D themselves. These drawings are just razzle-dazzle BS, because they do not contain any diagrams or dimensions of teeth. (tooth profile being the incompatible difference.) Utterly useless.

Sorry to semi-hijack this thread with the above... but it really really rubs me the wrong way to read how E3D is answering their customers questions. Dang, they were one of my go-to 'quality' suppliers. And this changes that. Firmly.

This

-

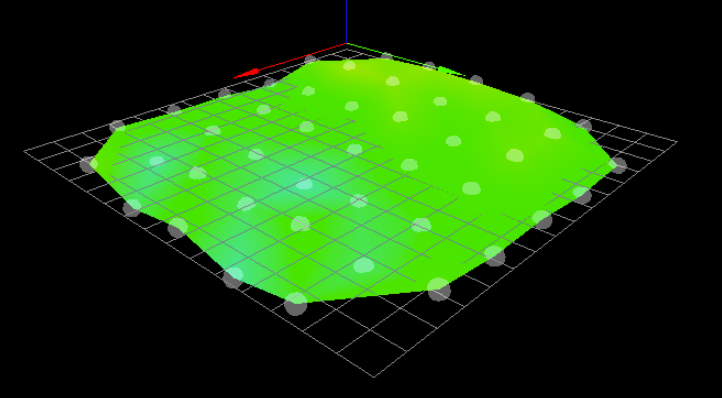

Anyway, back to the real topic. This printer, with toothed idlers, gets this kind of mesh maps. The ones it was getting with smooth idlers looked identical.

Mean error: 0.001 mm

RMS error: 0.040 mm -

@Danal said in Diagonal rod length on delta printer issues.:

They won't give a straight answer.

They don't? Perhaps when they first started selling them there was confusion but on al the product pages it's made quite clear they are 2GT belts and pulleys and only compatible with each other.

-

@Phaedrux said in Diagonal rod length on delta printer issues.:

@Danal said in Diagonal rod length on delta printer issues.:

They won't give a straight answer.

They don't? Perhaps when they first started selling them there was confusion but on al the product pages it's made quite clear they are 2GT belts and pulleys and only compatible with each other.

Their various pages and specifically their product pages are now a lot more clear. They do say "2GT" and they do say they are made by Unitta. However, they continue to have things like (as of about 10 seconds ago):

Gates Powergrip

2GT Belts

2GT BeltsWhere there ain't no such animal. "Powergrip

" applies only to GT2 Belts. In fact, the trademark registry proves that Gates US (maker of GT2) owns this trademark, and that Unitta (maker of 2GT) absolutely does not, and would technically be in TM violation to use it.

" applies only to GT2 Belts. In fact, the trademark registry proves that Gates US (maker of GT2) owns this trademark, and that Unitta (maker of 2GT) absolutely does not, and would technically be in TM violation to use it.Anyway... E3D has definitely improved; they've made more clear that they are selling Unitta 2GT. I suppose I can put away my cranky now.

-

@Danal It's definitely useful to know. I was thinking of getting some pulleys from them to go with my GT2 belts, but that wouldn't have worked out very well.

-

i just installed 2 Gates Powergrip

2GT Toothed on my printer.

2GT Toothed on my printer.is was not aware of this, but they seem to work.

My belts are gates unitta. so far its working.

-

No twist in my belts, I don't think there is room with the routing of them. Be too tight of a twist.

Wow that bed map is great. Linear bearings are great.

Thanks

Cory -

So I have some more information. Not sure that it helps with anything, but more information. I had ran a backlash routine before that dc42 had posted. But it was running in more in the center of the bed. I've been stuck thinking backlash was only in 'axis travel' and not somewhere else. That is poorly worded.

I decided to take a different approach after someone said it looked like one axis was causing it. I had assumed all 3 were, or I guess it could just be the rear tower as you don't see the problem there as much because of the probing pattern. So I wrote a program to probe at a radius of 100mm in line with each tower 4 times after an 30mm outward move then 4 after an 30mm inward move both inline with the tower. Here are my results.

12/2/2019, 1:42:41 AM: : G32 bed probe heights: -0.023 -0.017 -0.017 -0.017, mean -0.019, deviation from mean 0.003 12/2/2019, 1:43:13 AM: : G32 bed probe heights: -0.130 -0.136 -0.136 -0.136, mean -0.135, deviation from mean 0.003 12/2/2019, 1:43:46 AM: : G32 bed probe heights: 0.045 0.045 0.045 0.045, mean 0.045, deviation from mean 0.000 12/2/2019, 1:44:19 AM: : G32 bed probe heights: -0.111 -0.111 -0.111 -0.111, mean -0.111, deviation from mean 0.000 12/2/2019, 1:44:51 AM: : G32 bed probe heights: 0.040 0.040 0.040 0.040, mean 0.040, deviation from mean 0.000 12/2/2019, 1:45:24 AM: : G32 bed probe heights: -0.110 -0.117 -0.110 -0.110, mean -0.112, deviation from mean 0.003So there it is. Now if I move up and down with an indicator at one point, I don't see even a quarter of that.

Looking over the machine again, I noticed movement in a skate. I went to snug a screw and the bearing journal post inside broke off. Found cracks in all of them. I had replaced them earlier this year and emailed seemecnc if I could just buy the shells. They sent me replacements at no charge! Great people!

So that could have been the problem, or not. I probably over tightened the screws. Going to replace them with 3/4" long instead of the 1/2" provided to keep from putting all the stress at the weakest point.

Hopefully that was the whole problem all along. I would think any other backlash would show up in my previous tests.

Thanks

Cory -

@clytle374 Hey, that's great! Looking forward to seeing a nice flat bed mesh once you've changed the carriages.

Ian

-

Much better results. I replaced the skates and it didn't really help. I tightened the belts as tight as I could using long needle nosed pliers under the idler support pried against the frame. Again, I've been shooting in the dark on proper belt tension since 4 years ago when I built it. That made a major improvement.

That didn't give good first layers. But provided a delta calibration that was accurate. Simply turning off bed mapping was the answer there since it is just as likely to be wrong as right at any particular point on the bed.

Trying to decide if I build a tool or mod then machine to get good control when adjusting the tension.

Thanks again for all the advice!

Cory -

@clytle374 What did you do to fix the ridging? My uncle gave me a rostock max v2 and I upgraded it with the smart effector and duet wifi. I'm seeing very similar results to what you describe.

-

The ridges are caused by backlash in the joints or carriages. Check that the belts are taut and lubricate the joints. If you are using the magnetic rods, use a little silicone grease or white lithium grease on the ball studs.

-

@dc42 I checked the belts and they all seem tight. My joints are these plastic ball cup arms and seem to have no binding to them when moved. I think it might be my carriages or the motors. I emailed seemecnc to see if they had any suggestions.

I’m at my wits end with this. I have tried to run the mesh with the hotend off and on. Tried adjusting the delta radius and arm length but I keep seeing these ridges caused by backlash somewhere. I just can’t quite figure out where