Need your advice, V-Slot VS Linear Rail.

-

@Danal said in Need your advice, V-Slot VS Linear Rail.:

Me, personally, linear all the way. Considered as a percentage of the total cost of the printer, they are a trivial cost for noticeably better prints.

Especially because you are asking on the forums for one of the most "high end" controllers available. V-Slot/Roller goes with sub $50USD 8 bit boards. Linear goes with 32 bit boards. Or something like that.

Ouch - that's harsh! Especially the bit about "noticeably better prints". Unless you know something that I don't.

I get asked the question quite a lot on my blog and YouTube channel -i.e. "Why don't you use linear guides" and my answer is always the same - "the Open Builds V slot members are linear guides - so why would I want to attach a linear guide to a linear guide?"

But like @Phaedrux if was starting again, I might consider using "conventional" linear guides. Not because I believe it will give my any better prints but because it would likely save me some money. At the last count on my CoreXYUVAB I have 60 odd sets of twin bearing Delrin wheels at around £10 a pop. So I've spent upwards of £600 on "non-linear guide" linear guides if you get my meaning.

Having said all that, they have served me well over thousands of hours of printing with no maintenance and with no problems or issues of any sort. They do need to be set up and adjusted properly to start with though. I'd say the main disadvantage of Open Builds V slot is that the carriages tend to be a bit big in comparison.

-

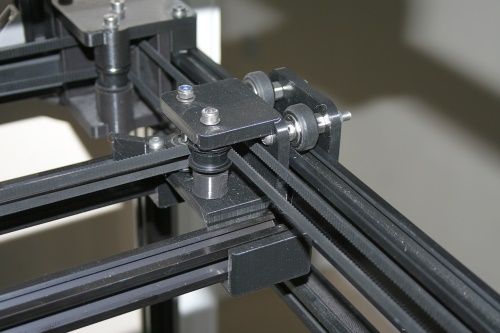

@Rudy2A One piece of advice if you do decide to go the Vslot route is not to use a single gantry plate as shown in your first picture because the bolts could potentially "flex". Use double plates so that the bolts are fixed at both ends rather than the cantilevered arrangement that is so often used. This kind of thing

-

Hi,

I have had only one printer that used the V-slot approach. The rebuilt printer using linear rails works much better.

Frederick

-

i second linear rails.

i swapped my v slot rails on the ender 3 y axis with linear rails and its a lot more ridgid than before.

my other 2 printers are linear rails.

-

I personally experienced exactly what @deckingman mentioned - any "proper" linear rail might be cheaper than the whole V-Slot solution these days. And to make matters worse, there are better quality (more rigid!) standard extrusions that are cheaper to buy. When deciding on which way to go when my wheels on the Y-axis of the WorkBee CNC started to exhibit problems, supported round linear rails (safer for not very rigid machine, and a desktop CNC like the WorkBee is usually not very rigid!) where less than half the price (the WorkBee has 28 wheels on the Y axis!!!).

I still have to handle the X and Z axis (due early next year!), but the improvement is visible!

-

vslot - 3 to 8 rollers usually made out of %@^*& material rolling on the aluminium profile .. both rollers (wheels) and the profile deform over time, aluminium while light is also super soft, dust and other crap collect, stick to the rollers and additionally kills precision ... so, it's cheap, it's "ok", but is far from ideal ... I have not seen anywhere the moment of force these are handling for all degrees of freedom!! ..

hiwin style linear rail - hardened balls rolling over hardened steel rail, 40 up to many hundreds of balls in each wagon -> many many many points of contact. properly specified acceptable moment of force for all degrees of freedom. relativly closed design so dirt does not collect a lot .. the con side is you can't use the rails as construction material (like with vslots) so you have added cost and weight. additional "problem" is that there are some reeeeeally shitty prc made rails that have huge tolerances and balls made out of crap so you should know what you buy from where

if you are drafting your prints (most of my printers are running in "draft" mode) the difference in quality is irrelevant, the layers not being laid ideally on top of each other are not a big deal.... but if you do a high quality prints too, there's huuuuuge difference between new v-slot and used rails .. and v-slot with few hundred hours under it's belt .. ...

-

@smece said in Need your advice, V-Slot VS Linear Rail.:

huuuuuge

What's a few microns between friends.

What's a few microns between friends. -

Another advantage to linear guides is that their compact size makes it easier to enclose the printer if you want to. Usually you can just bolt some side panels to the printer's frame.

The V-slot wheel carriages are running on the printer's frame, so an enclosure has to be built to enclose the whole thing.

-

to to high quality Linear Rail , linear rail more rigid than V-solt

V slot you need to maintain form time to time and the wheels need to change almost every 2 years -

@yaman The rigidity of the linear rail depends on the rigidity of the member that it's bolted to. Likewise the rigidity of vslot depends on the size of the chosen profile. Changing wheels every 2 years is absolutely not necessary if they are tensioned correctly in the first place. Likewise adjusting them.

I'll just reiterate that my machine with it's 5Kg plus of moving mass has run for thousands of hours with no adjustment or replacements and motion wise, it worked as well when it was demonstrated at the TCT show in 2017 as it did a couple of months ago in 2019.

I'm not advocating one system over the other but there is a lot of misinformation about vslot in this thread. Ultimately the quality and reliability of both "conventional" linear guides and vslot linear guides is down to the quality of the components used, especially bearings, and also how each one is fitted and aligned. -

I am not convinced about linear rail (as defined in the OT). I would go with what Deckingman says. I have read SO MUCH bad experiences with linear rail, especially if you want to go cheaper than the original HIWIN ones (and most of us do want that!).

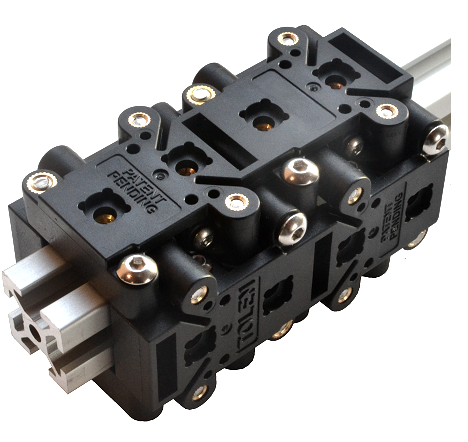

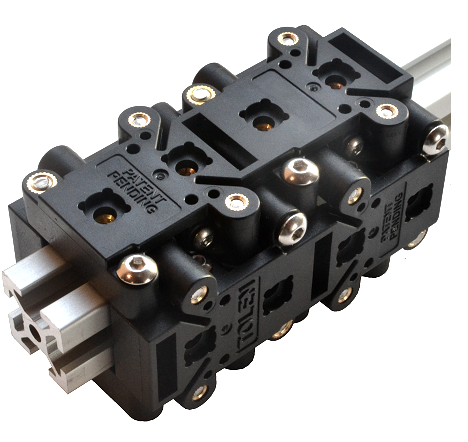

However I would like to bring these into the equation:

Look at the specs. they look very promising and are much cheaper!

https://us.misumi-ec.com/vona2/detail/110302192160/?HissuCode=PLRH25-560Or how do we feel about these:

Specifics at: https://www.exoslide.com/

For 20x20, 20x40 and 40x40 available. But maybe not the cheapest solution. -

@DeltaCon .........and there is also Igus Drylin which is a route I might consider if ever I build another machine

One thing that hasn't yet been mentioned is noise. Vslot (and Drylin) are practically silent. My massive CoreXYUVAB with all 6 axes running at high speed is quieter than my old Mendel used to be.

-

@deckingman drylin is an interesting mention, but they have to be choosen wisely and the machine has to be properly designed to address the fact that you can't have gliding motion without play. It is possible though, and I've seen some stunning results from printers with drylin-everything.

They are practically silent as well.My own printer, which hasn't been introduced here yet, runs on drylin W (square shape). It's silent (loudest noise comes from the fans, or the steppers when in spreadcycle mode), dust-proof (yes - I'm not using my machine enough, but the drylin rails don't care), but there is some play in the motion system which makes for not-perfect parts (round parts have flat spots). Had I chosen drylin W with the round shape, I could have picked bearing blocks with set screws to tension the gliding elements.

Drylin N is also widely used in printers, as a cheaper alternative.

-

@deckingman said in Need your advice, V-Slot VS Linear Rail.:

@DeltaCon .........and there is also Igus Drylin which is a route I might consider if ever I build another machine

That's an interesting addition indeed. Already any idea of which type would be to be preferred?

And wow... Interesting concept fo a delta printer

https://www.youtube.com/watch?v=kyAkmN8WEes&feature=youtu.be -

Can a linear rail stand on its own as a X axis or does it need to be attached to an aluminum extrusion for extra strength?

(considering to upgrade my HEVO but thinking of the moving mass in Y direction).

-

@zapta said in Need your advice, V-Slot VS Linear Rail.:

Can a linear rail stand on its own as a X axis or does it need to be attached to an aluminum extrusion for extra strength?

(considering to upgrade my HEVO but thinking of the moving mass in Y direction).

I've seen folks do that but I wouldn't.

Frederick

-

@zapta said in Need your advice, V-Slot VS Linear Rail.:

Can a linear rail stand on its own as a X axis or does it need to be attached to an aluminum extrusion for extra strength?

(considering to upgrade my HEVO but thinking of the moving mass in Y direction).

That would depend on the length of the guide and the mass it has to carry or any other forces that might be applied, e.g. belt tension. I guess you might get away with it if the length was short and the mass was low but otherwise it is likely to deflect. Which brings me back to something I said earlier which is, if you have a frame member made from V slot such as Open Builds type and you want it to be a linear guide, do you add gantry plates and Delrin wheels, or do you bolt on another complete linear guide? I personally don't think there is a right or wrong way to do it and the choice largely comes down to other factors like cost, personal preference, what fits best in the space available, noise, etc etc.

-

@zapta said in Need your advice, V-Slot VS Linear Rail.:

Can a linear rail stand on its own as a X axis or does it need to be attached to an aluminum extrusion for extra strength?

(considering to upgrade my HEVO but thinking of the moving mass in Y direction).

The RailCore designers have chosen to do exactly that, but that is also the reason the railcore design is limited to 300mm. Personally Iwould rather see an extrusion used.

-

linear rails are not meant to stand on its own. It might work if you take bigger ones (like mgn15).

but the recommendation is to mount them on something sturdy. -

@DeltaCon said in Need your advice, V-Slot VS Linear Rail.:

However I would like to bring these into the equation:

Look at the specs. they look very promising and are much cheaper!

https://us.misumi-ec.com/vona2/detail/110302192160/?HissuCode=PLRH25-560Seen a huge laser engraver made with these and is crazy fast and precise .. no clue how much load they can take (on the negraver they only house a mirror) but without load they are precise ... pretty loud one might say but..

Or how do we feel about these:

Specifics at: https://www.exoslide.com/

For 20x20, 20x40 and 40x40 available. But maybe not the cheapest solution.I experimented with very similar solution some years ago, the problem I had is that aluminium deformed over time ... maybe it was too tight, dunno, but I gave up using it for 3d printers, I still use this type of linear guide for my touch screen human finger simulators

(they carry only few grams and precision is not important, 1mm error is acceptable)

(they carry only few grams and precision is not important, 1mm error is acceptable)