Unsolved Dual Z-Probe at IDEX System

-

Hi everyone...

I am currently building a large format 3D printer with IDEX system.

I've already set up an IDEX, but now I want to try something new.I use the Orion Piezo sensor as a Z-probe. this works very well in other printers.

and now my question.Can I also connect a piezo sensor as a z-probe or other sensor on the second toolhead (i.e. U-axis)? so that I measure both toolheads beforehand and save the offsets. That would save a lot of adjustment work.

if so, how would you implement this in the firmware?

Many thanks to all of you!

Regards Christian (CR-3D)

-

Any Ideas?

-

I run an IDEX system, but I have not put any thought into attaching a probe to the second hotend. I have my BLTouch on my X carriage, with the U carriage being the second hotend.

https://duet3d.dozuki.com/Wiki/ConfiguringMultipleIndependentXcarriagesCartesian

"If you home Z using a Z probe, then that probe should be mounted on the X carriage..."

Ignoring if the firmware could support two probes for two different hotends, here is how I imagine the calibration procedure will go

- Determine X, Y and Z offsets for probe0 on Carriage X

- Determine X, Y, and Z offsets for probe1 on Carriage U

- Determine the X and Y tool offset for Carriage U

Why step three? Well when working with IDEX systems, I find its best to assume no tool offset on the X carriage. While the X and U carriages (typically) share the same Y axis, you will have some X and Y offset in the U carriage due to tolerance stackup in assembly - the parts for the X and U carriage will not be made perfectly the same. You'll essentially have to zero the U carriage X and Y to a predetermined point established by the X carriage (e.g. X0, Y0 relative to the X carriage).

If you change a nozzle on any hotend, you'll probably need to do all three (specifically Z offsets).

With the probe only on the X axis, the process looks like

- Determine X, Y and Z offsets for probe0 on Carriage X

- Determine the X, Y and Z tool offset for Carriage U

Again, unsure if there is a mechanism in the firmware, or with conditional gcode, object model, etc, that can aid in two probes.

-

RRF3 has support for multiple probes, how that would relate to the coordinate system I am not sure.

-

@Phaedrux said in Dual Z-Probe at IDEX System:

RRF3 has support for multiple probes, how that would relate to the coordinate system I am not sure.

Ok thank you for your answers!

@sebkritikel: Do you think I have to calibrate also the X and Y offset after a nozzle change?

-

You can use a G30 S-2 command to probe the bed and automatically adjust the tool Z offset to make the stop height equal to the trigger height. Obviously you need to make sure that only the nozzle of the active tool can contact the bed, for example by having the other tool off the edge of the bed when you probe.

To do ditto prints or mirror prints, you need to have both nozzles at the same height.

-

Ok fantastic!

If the build is finished the next weeks I will test it and report here

Thank you!

-

This post is deleted! -

Ok now I want to configurate the Dual Z-Probe at my IDEX with Duet3 V1.0 and RRF 3.1.1

Where do I have to define the second Z sample with the K parameter? In the config?

How do I then trigger a measurement process with the second Z-sample (mounted on the second printhead)?

-

Check these docs, particularly for the K parameter to reference the different probes.

https://duet3d.dozuki.com/Wiki/Gcode#Section_G30_Single_Z_Probe

https://duet3d.dozuki.com/Wiki/Gcode#Section_G31_Set_or_Report_Current_Probe_status

https://duet3d.dozuki.com/Wiki/Gcode#Section_M558_in_RepRapFirmware_Num_3 -

Thank you!

I know all three digits of the GCode table, but I just don't know how to implement it.

I understood the commands that I need at itself, but not how I select the second probe so that it references it.

-

Well if you read the K parameter description of those three commands you'll see how to use each to target your desired probe.

You'll need an M558 and G31 for each probe. K0 and K1. Then when you want to probe with G30, specify the probe number with K0 or K1.

-

Ok i configured it like that:

Config.g

; Z-Probe (Piezo) M558 P5 I1 C"!io3.in" R1.0 K0 H5 F200 T6000 ; Z probe type -> Piezo M558 P5 I1 C"!io4.in" R1.0 K1 H5 F200 T6000 ; Z probe type -> Piezoconfig-override.g

; Z probe parameters G31 T0 P600 X0.0 Y0.0 Z-0.045 G31 T1 P600 X0.0 Y0.0 Z-0.045Homez.g

; homez.g ; called to home the Z axis ; M106 P0 S0 G90 ; absolute positioning G1 X220 Y200 U600 F8000 ; first bed probe point -> move X to the middle of the Bed, U outside and home Z T0 G30 S-2 K0 G1 X0 Y200 U300 F8000 ; first bed probe point -> move X outside, U to the middle of the Bed and home Z T1 G30 S-2 K1The normal homing with Tool 0 works fine, but if he references Tool 1 he will infinitely move the Z-axis in the positive direction ...

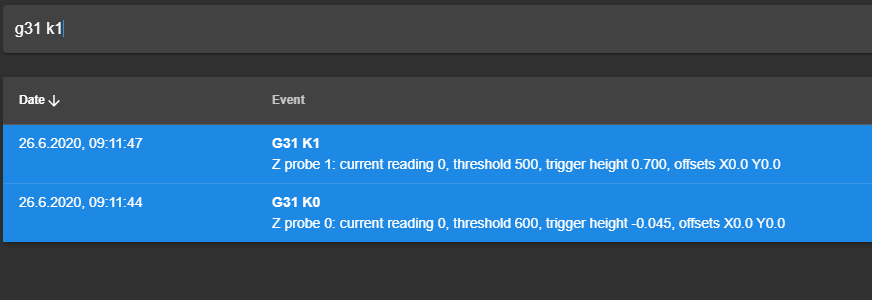

I also get not the right values from the second probe:

Any ideas?

-

@CR3D said in Dual Z-Probe at IDEX System:

config-override.g

; Z probe parameters G31 T0 P600 X0.0 Y0.0 Z-0.045 G31 T1 P600 X0.0 Y0.0 Z-0.045I don't think you'll be able to use config-override.g for the G31 for this purpose because it doesn't have the K value. According to the wiki entry the T value is not used in RRF3. So put those G31 entries in config.g and change the T0 and T1 to K0 and K1.

The behaviour you're seeing makes sense because the first probe is k0 by default.

-

@Phaedrux Thank you!

Ok i put the G31 commands into the config.g

Ok i put the G31 commands into the config.g; Z-Probe (Piezo) M558 P5 I1 C"!io3.in" R1.0 K0 H5 F200 T6000 ; Z probe type -> Piezo M558 P5 I1 C"!io4.in" R1.0 K1 H5 F200 T6000 ; Z probe type -> Piezo G31 K0 P600 X0.0 Y0.0 Z-0.045 G31 K1 P600 X0.0 Y0.0 Z-0.045Homeall.g

G90 ; absolute positioning G1 X220 Y200 U600 F8000 ; first bed probe point -> move X to the middle of the Bed, U outside and home Z T0 G30 S-2 K0 G1 X0 Y200 U300 F8000 ; first bed probe point -> move X outside, U to the middle of the Bed and home Z T1 G30 S-2 K1but unfortunately he still does not reference sample 2 correctly ... the print bed moves towards max ....

-

I will have to run this past @dc42 to see what we're missing.

-

I hope @dc42 can help me!

It is not running till yet

-

@CR3D said in Dual Z-Probe at IDEX System:

but unfortunately he still does not reference sample 2 correctly ... the print bed moves towards max ....

Please explain exactly what you mean:

- Does a G30 K1 command work correctly?

- Does a G30 K2 command work correctly? If not, what does it do?

Please post your complete config.g and config-override.g files as they now are.

-

When I run G30 K0 (for Probe 0 at the X-Carriage) in the console after homing X, Y and U manually it works

When I run G30 K1 (for Probe 1 at the U-Carriage) I also have to trigger the Probe at the X-Carriage and not at the U-Carriage.

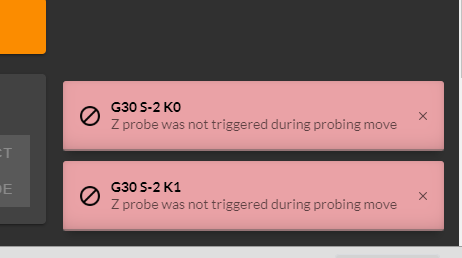

When I run G30 S-2 K0 and G30 S-2 K1 -> the Z-Axis does not move and the error message pop up...

When I run G28 ... the X, Y and U Axis homes correctly, then the X-Carriage moves to the middle of the print bed -> probing (Error Message like above), then the U-Axis moves into the middle (Error Message like above)

and then the Z-Axis moves with highspeed into the max direction (away from the Z-Probe)Here are my config files:

Config.g

; Configuration file for Duet 3 (firmware version 3) ; General preferences G90 ; send absolute coordinates... M82 ; and absolute extruder moves M550 P"I444-S" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards Y0 M569 P0.1 S0 ; physical drive 0.1 goes forwards Y1 M569 P0.2 S0 ; physical drive 0.2 goes forwards X M569 P0.3 S0 ; physical drive 0.3 goes forwards X1 (U) M569 P0.4 S0 ; physical drive 0.4 goes backwards E0 M569 P0.5 S0 ; physical drive 0.5 goes backwards E1 M569 P1.0 S1 ; physical drive 1.0 goes forwards Z0 M569 P1.1 S1 ; physical drive 1.0 goes backwards Z1 M569 P1.2 S1 ; physical drive 1.0 goes forwards Z2 ;New Mapping M584 X0.2 Y0.0:0.1 U0.3 Z1.0:1.1:1.2 E0.4:0.5 ; set drive mapping M350 X16 Y16 U16 Z16 E16:16 I1 ; configure microstepping M92 X80.00 Y35.56 U80 Z1600 E415:415 ;set steps per mm M566 X900 Y900 U900 Z12 E120:120 ;set maximum instantaneous speed changes (mm/min) M203 X60000 Y60000 U60000 Z1000 E9000:9000 ;set maximum speeds (mm/min) M201 X2000 Y2000 U2000 Z200 E1000:1000 ;set accelerations (mm/s^2) M906 X1400 Y4200 U1200 Z1500 E1000:1000 I30 ;set motor currents (mA) M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 U0 Z0 S1 ; set axis minima M208 X460 Y500 U460 Z420 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!io1.in" ; active-high endstop for low end on X via pin io0.in M574 U2 S1 P"!io0.in" ; active-high endstop for high end on U via pin 1.io1.in M574 Y2 S1 P"!io2.in" ; active-high endstop for high end on Y via pin 1.io2.in ; Z-Probe ;M558 P5 C"^!io5.in" H1 F500 T12000 ; Z probe type -> Induktiv ;G31 P100 X0.0 Y0.0 Z2.0 M558 P5 C"!io3.in" R1.0 K0 H5 F200 T6000 ; Z probe type -> Piezo M558 P5 C"!io4.in" R1.0 K1 H5 F200 T6000 ; Z probe type -> Piezo G31 K0 P100 X0.0 Y0.0 Z-0.30 G31 K1 P100 X0.0 Y0.0 Z-0.30 M557 X50:410 Y00:340 P04:04 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp1" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M308 S2 P"temp2" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin temp2 M950 H2 C"out2" T2 ; create nozzle heater output on out2 and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ; Fans M950 F0 C"out4" ; create fan 2 on pin out4 and set its frequency M106 P0 S0 H-1 ; set fan 2 value. Thermostatic control is turned off M950 F1 C"out5" ; create fan 3 on pin out5 and set its frequency M106 P1 S1 H2:1 T50 ; set fan 3 value. Thermostatic control is turned off ; Tools M563 P0 S"Links" D0 H1 F0:2 ; define tool 0 G10 P0 X0 Y0 Z0 S0 R0 ; set tool 0 axis offsets G10 P0 R0 S0 ; active and standby temperatures M563 P1 S"Rechts" D1 H2 X3 F1:3 ; define tool 1 G10 P1 Y0 U0 Z0 S0 R0 ; set tool 1 axis offsets G10 P1 R0 S0 ; active and standby temperatures ; Custom settings are not defined ; Open Door Switch M581 T0 C"1.io3.in" S0 C0 ;trigger #2 (calls trigger0 -> Emergency-Stop) M582 T0 ; LEDs ; Farbe Blue M950 F2 C"out3" Q500 ; create fan 3 on pin out5 and set its frequency M106 P2 S125 ;set fan 3 value. Thermostatic control is turned off ; Farbe Red M950 F3 C"1.out0" Q500 ; create fan 3 on pin out5 and set its frequency M106 P3 S0 ;set fan 3 value. Thermostatic control is turned off ; Farbe Green M950 F4 C"1.out1" Q500 ; create fan 3 on pin out5 and set its frequency M106 P4 S150 ;set fan 3 value. Thermostatic control is turned off ; Farbe White M950 F5 C"1.out2" Q500 ; create fan 3 on pin out5 and set its frequency M106 P5 S0 ;set fan 3 value. Thermostatic control is turned off ; Miscellaneous M501 ; load saved parameters from non-volatile memory T0 ; select first tool M572 D0 S0.03Config-override.g

; config-override.g file generated in response to M500 ; This is a system-generated file - do not edit ; Heater model parameters M307 H0 A106.1 C65.0 D3.4 S1.00 V24.1 B0 M307 H1 A1014.5 C333.6 D4.6 S1.00 V24.1 B0 M307 H2 A340.0 C140.0 D5.5 S1.00 V0.0 B0 ; Workplace coordinates G10 L2 P1 X0.00 Y0.00 Z0.00 U0.00 G10 L2 P2 X0.00 Y0.00 Z0.00 U0.00 G10 L2 P3 X0.00 Y0.00 Z0.00 U0.00 G10 L2 P4 X0.00 Y0.00 Z0.00 U0.00 G10 L2 P5 X0.00 Y0.00 Z0.00 U0.00 G10 L2 P6 X0.00 Y0.00 Z0.00 U0.00 G10 L2 P7 X0.00 Y0.00 Z0.00 U0.00 G10 L2 P8 X0.00 Y0.00 Z0.00 U0.00 G10 L2 P9 X0.00 Y0.00 Z0.00 U0.00Homeall.g

; homeall.g ; called to home all axes M106 P0 S0 ; Part cooling Fan off G91 ; relative positioning G1 H2 Z10 F6000 ; lift Z relative to current position G1 H1 X-650 Y550 U650 F5000 ; first pass XYU G1 H2 X5 Y-5 U-5 F6000 ; go back a few mm G1 H1 X-20 Y20 U20 F360 ; second pass XY G90 ; absolute positioning G1 X270 Y170 U460 F20000 ; first bed probe point -> move X to the middle of the Bed, U outside and home Z G30 S-2 K0 G1 X0 Y170 U200 F20000 G30 S-2 K1 -

@CR3D can you please show your tfree0.g, tfree1.g, tpost0.g and tpost1.g files? You selected T0 in config, after homing the tool is deselected, maybe there is code in the file which is wrong.

"Then use the tfree#.g files (where # is the tool number) to park a tool when you stop using it. To park a tool you could just home it" in https://duet3d.dozuki.com/Wiki/ConfiguringMultipleIndependentXcarriagesCartesian