Lifting extruder E1 0.5mm

-

Hi dear friends.

I'm building a dualextruder with a lifting function of E0 extruder. I want to keep the E1 static. So what is a good gcode for descending E1 0,5 mm with Z motor before extruding? I quess I have to lift it back after printing too? The gcode would be located to Cura printer settings, "Extruder starting code"

Thank You. -

I think you could use the tool change macros.

https://duet3d.dozuki.com/Wiki/Multiple_tools_and_Tool_change_macros

Then when cura changes tools with T0 T1 the macros will execute.

-

ok, I try tool change macros.

I found commands G91 X0 Y0 Z0.5 to set relative position and

G92 X0 Y0 Z0 to pull it back to absolute coordinates -

Ok, I put z value to 0.6 but that did not work, also -0.6 had no effect. Config.g looks like this:

M563 P1 D1 H2 F0 ; define tool 1

G10 P1 X0 Y0 Z0.6 ; set tool 1 axis offsets

G10 P2 R140 S0 ; set initial tool 1 active and standby temperatures to 0C -

@Pertti said in Lifting extruder E1 0.5mm:

G92 X0 Y0 Z0 to pull it back to absolute coordinates

G92 sets the current position

G90 is absolute positioning

G91 is relative positioningAre you trying to set an offset or lift the tool?

-

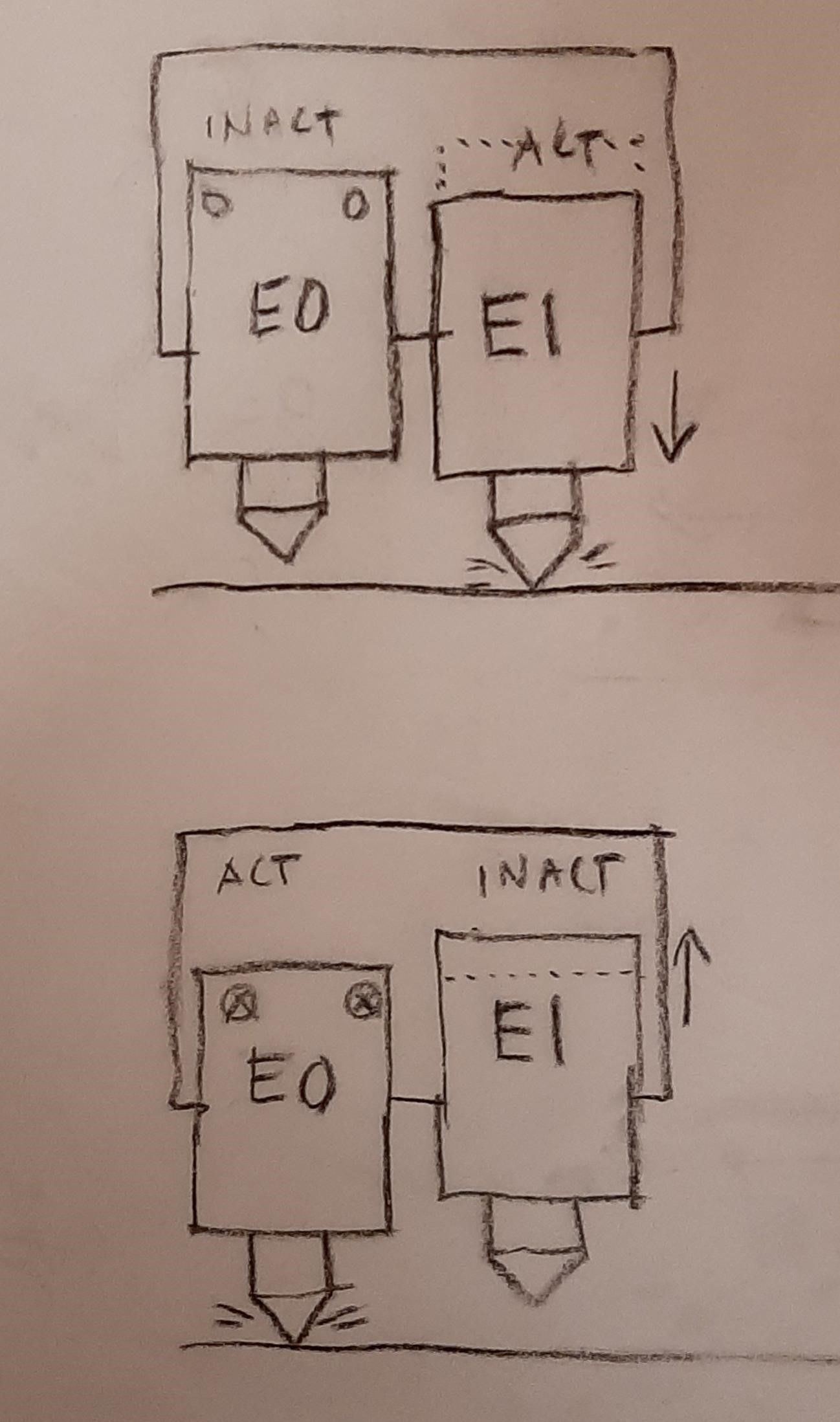

I'm trying to lift the inactive printhead while the is active is deployed.

-

Does it have it's own independent z axis? What actuates the lifting?

-

The bed is supposed to move up a little while E0 is active. I have a separate actuator to E1, which goes up when not used.

-

Ok, I am lifting both bed and the other printhead. But E0 is "static" and E1 is movable. Sorry I was not clear enough.

-

Hope this picture clarifies my idea.

-

Looks like Cura extruder starting code (absolute) has effect only in the beginning of the sift (E0---E1), It moves Z immediately back. If I use relative coordinates then the printhead runs at the opposite corner...outch!

Maybe it is better to provide an actuator to both hotends. -

How much travel do you have on E1? I think what you want to do should work, but I'm not sure of the best tool change code to achieve it.

How is E1 lifted? What is the mechanism? Does it have its own axis? Is it a servo?

-

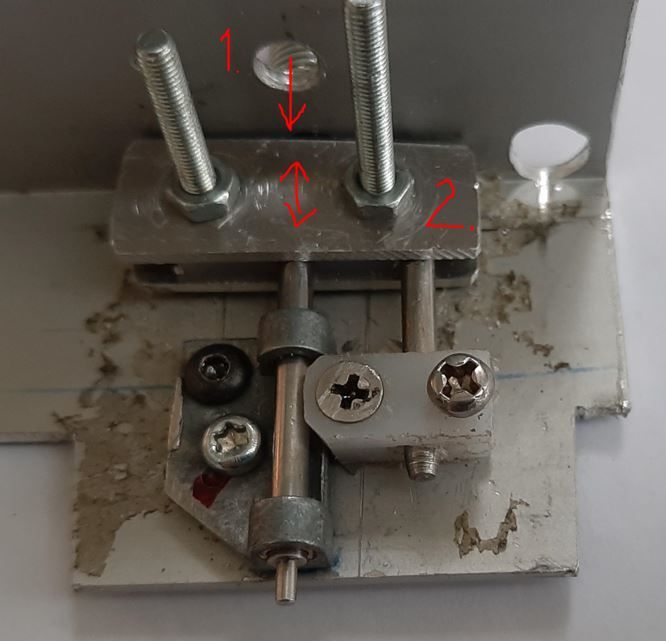

Here´s the mechanism from a recycled cd-rom station.

- filament input

- moving sleigh

hotend is not in this picture, but I use cr-10 style one.

Now the interesting part is how to move the hotend. I think I open a new thread for that. It uses the E1 steppermotor.

The filament pushes the nose down when extruding.

The movement is around 1mm. I want to keep it as small as possible. Of course this needs many details and a lot of tuning, but I think I can make it work. I have not seen this kind of mechanism being used, so I can call it my invention. If somebody has seen this kind of solution before, please tell...

-

@Pertti said in Lifting extruder E1 0.5mm:

It uses the E1 steppermotor.

What axis have you assigned it?

-

No axis at all. The moving force comes by the filament. When extruding, the pressure pushes the nozzle down.

-

Axis E1 is signed to the steppermotor E1

-

So it's a passive system based on if it's extruding or not?

-

@Phaedrux -Yes.

-

That's very interesting, but I'm not sure how to make that work. Your original post talks about using the Z motor to move it, but I don't see how you mean to use that.

-

Actually Z motor is used in the first place for "negative z-hop" for the E1 extruder, which is static. Anyway I quit that idea and moved to make both extruders dynamic. I completed the idea with 2 pc Linear Guide MGN12H.