PID tuning problems

-

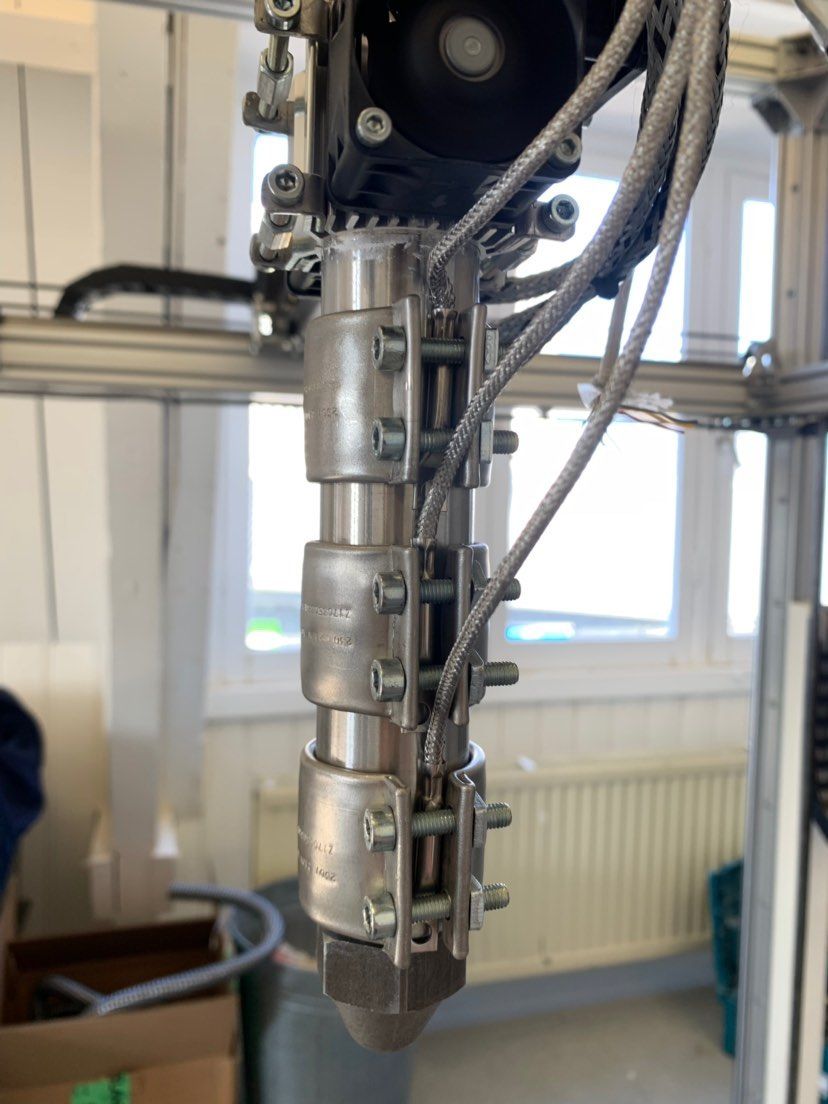

I have almost finished building a pellet extruder for my 3d printer. It uses a 16mm screw and barrel with 3x240watt band heaters with a PT1000 sensor for temperature monitoring.

The outer diameter of the barrel is 35mm so there is a LOT of mass that needs to be heated. I am trying now to configure the PID parameters for the heaters but I just can not get it to work. I ran it lots of times, put in the results but still when I put the heater on to let's say 100C it overshoots by 15C and after that keeps fluctuating around the desired temperatur.

Anybody out here that can help me out? The PT1000 sensors aren't mounted the best possible way and I already ordered some isolation material to wrap the whole extruder in. But still I think it should also work like this....

See files attached

-

(Oh my!)

Could you add your config.g (and config-override.g) so we could see what you're working with please.

Looks like you're trying to use three heaters and three sensors on the same tube, that might lead to fluctuations as the PIDs try to compensate against each other?

-

I got it kind of figured out, all heaters where in bang bang mode, didn't know how to turn that off....

I am not at the point of turning on all 3 heaters but I am also a bit afraid that the fluctuations might occur...

config file is attached in the first post.

-

M350 Z16 E16 I1 E0 I0 ; Configure microstepping with interpolation

this command makes no sense.

e and i are double.your config is missing the start

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Printer" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S1 ; enableTelnet -

have you thought about using an induction coil to heat the hotend?

-

The start is not in there since it included the password... as far as the interpolation this works, I'll clean it up later, I am more busy with the heaters right now...