ClearPath Servo Motors Testing - So far so good

-

20 years ago I wrote an article on how to tune PID controllers from a DIY type perspective.

http://www.tcrobots.org/articles/Kilian120.pdf

I have since gotten a BS in Mechatronics and we learned how to tune PID controls with physics and math, but I've forgotten a lot of the theory and the math, so I'm not sure I could do it from scratch right now.

But if you have tuning questions, I can try to help.

-

@alankilian thank you very much! the more resources the better! I am keeping that in mind

-

Just wanted to jump in here and mention that with high acceleration and deceleration values with servos the deceleration can actually cause a switching power supply to shutdown due to over volting of the power bus. The common way of dealing with this is a brake chopper circuit, it uses a resistor to blead off voltage above a specified value to prevent over volting. These circuits also sometimes use a capacitor bank to absorb excess voltage as well.

Most switch mode power supplies will shutdown around 2-4 volts above the configured voltage.

That's not to say that you may not run into shutdowns under high acceleration due to boost current being used by the servo drive for a longer period of time. -

@Mabover In my sand table when I set acceleration to 20k mm/sec^2 the power supplies start shutting down. I thought the supplies were shutting down because the motors were pulling too much current. If it runs at 2000 mm/sec I start getting over voltage messages from the Duet board. At 2000 mm/sec it's exceeding the 3k rpm max spec for the motors, and as I understand it, the max rpm spec is based on back EMF generation so it makes sense that I get the over voltage messages.

I limit maximum speed to 1500 mm/sec now and keep acceleration down to 15k mm/sec^2 or less and don't seem to have any problems. Both are much higher than I really need the machine to move for a sand table- at speeds of 500 mm/sec and acceleration of 5k it tends to start throwing the sand around...

-

With servo (or linear) motors and very high accelerations is retraction necessary?

-

@akstrfn said in ClearPath Servo Motors Testing - So far so good:

With servo (or linear) motors and very high accelerations is retraction necessary?

With pressure advance the requirement for retraction would be considerably less, but some retraction may still be required. The melted plastic doesn't stop flowing.

-

@Phaedrux I guess pressure advance would be necessary to reduce the pressure but the retractions from slicer seem unecessary because the plastic should be substantially slower than the print head moving to new location. I hope we'll get some results on this from people having these extreme speed setups finished.

-

Hi

Regarding the clearpath's, does anyone know if I Can use an External 5v PSU for the Step+, Dir+ and En+ signal?

Im a little confused to how this work.

Just to be clear, only Step-, Dir- and En- are connected to e.g Drive 5,And all the + connections are wired togheter and connected to the 5V+?

Therefor im wondering If I Can use an external 5V supply so I can use the Drive 10 and 11, and keep my Duex 5.Best regards

JHB -

@Mabover said in ClearPath Servo Motors Testing - So far so good:

Just wanted to jump in here and mention that with high acceleration and deceleration values with servos the deceleration can actually cause a switching power supply to shutdown due to over volting of the power bus. The common way of dealing with this is a brake chopper circuit, it uses a resistor to blead off voltage above a specified value to prevent over volting. These circuits also sometimes use a capacitor bank to absorb excess voltage as well.

Most switch mode power supplies will shutdown around 2-4 volts above the configured voltage.

That's not to say that you may not run into shutdowns under high acceleration due to boost current being used by the servo drive for a longer period of time.Adding additional capacitance between VIN and ground will help absorb the motor back emf. Duet 2 already has 100uF per driver, and Duet 3 MB6HC has 220uF per driver. These are enough for the internal drivers; but if you use external drivers and high-current motors then you may need more, perhaps an extra 4700uF or 10000uF.

-

@jbergene said in ClearPath Servo Motors Testing - So far so good:

Therefor im wondering If I Can use an external 5V supply so I can use the Drive 10 and 11, and keep my Duex 5.

The drive 10/11 outputs on CONN_LCD are only rated at 3.3v and low current, so you need an external 5V buffer to provide 5V output at up to 20mA.

-

A word to the wise having built several Clearpath retrofits for CNC machines...Buy the Clearpath official power supply (or two if you need them) - to correctly power your motors. Cheesing out on the power supply with these motors will result in chasing your tail, pointing fingers in the wrong direction and a host of other problems that will cost you more than just buying the right kit to begin with. (I say this from 1st hand experience). They're not 'cheap' but they're what you need to do it right.

-

@BDubs Thank you very much for this advice.

-

@Mirage - You got it. They're pretty impressive motors. If you spend a few more dollars for the 6400 CPR ones, it's worth it.

3 to 5:1 reduction on them (unless running a screw) is also advised to gain some mechanical resolution....which is always preferable to 'electronic resolution'. The Duet should have more than enough 'pulsestream' to go as fast as you'd want to go with them.

-

@Mirage, looking and your design page, it seems that you are addressing all the things I wanted to improve on my HEVO (which serves me well otherwise). That's very impressive and I will definitely follow up.

If it's ok with the mods be useful to start here a thread to follow up progress of your project.

I wonder what extruder you have in mind. For me a direct extruder is a 'must' but it seems that your design will be able to move it fast and accurantly.

-

Have you tried using the "RAS"/Regressive Auto Spline feature in the ClearPath Servos? Did is mess with pressure advance or extruder timing?

At low speeds it might not be noticable (@ 100mm/s, 25ms is 2.5mm). But where you plan to run the HevORT, the machine covers 25mm in 25ms.

-

Hi!

I'm converting an old Therwood machine into a 3D printer with a Typhoon head / ClearPath motors.

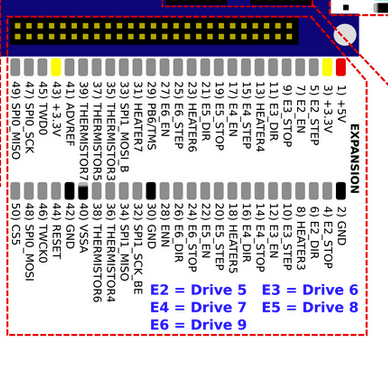

Would it be possible to make the 5V change at the ribbon cable going into the expansion board?

Cut 3 and 43 and connect them to pin 1 (5V) ? Thereby running the exansion board at 5V? Are the ICs on the exp board 5V tolerant and would that config work with clearpath SDHP motors? Or Shall I simply do the above and wire 3 servos to the 5V heater pin?