Status problem

-

Dear friends

I have a problem with head position in Delta printer. At HOME 2 coordinates X and Y =0, but Z =999? I use RepRap 2.03 firmware. May be mistake in firmware? My config and homedelta are applied:

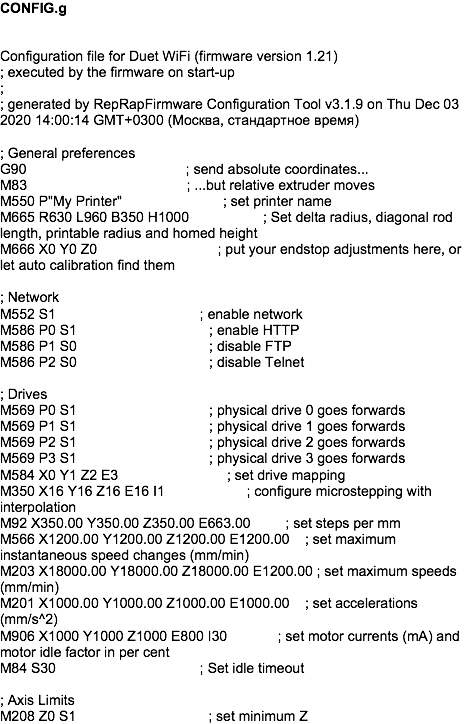

CONFIG.g

CONFIG.gConfiguration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.9 on Thu Dec 03 2020 14:00:14 GMT+0300 (Москва, стандартное время); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Printer" ; set printer name

M665 R630 L960 B350 H1000 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X350.00 Y350.00 Z350.00 E663.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 Z0 S1 ; set minimum Z; Endstops

M574 X2 Y2 Z2 S1 ; set active high endstops; Z-Probe

M558 P4 H5 F120 T6000 ; set Z probe type to switch and the dive height + speeds

G31 P50 X0 Y0 Z3.5 ; set Z probe trigger value, offset and trigger height

M557 R85 S20 ; define mesh grid; Heaters

M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

Config.g.bak

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.9 on Thu Dec 03 2020 14:00:14 GMT+0300 (Москва, стандартное время); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Printer" ; set printer name

M665 R630 L960 B350 H1000 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X350.00 Y350.00 Z350.00 E663.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 Z0 S1 ; set minimum Z; Endstops

M574 X2 Y2 Z2 S1 ; set active high endstops; Z-Probe

M558 P4 H5 F120 T6000 ; set Z probe type to switch and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 R85 S20 ; define mesh grid; Heaters

M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

HOMEDELTA.G

; homedelta.g

; called to home all towers on a delta printer

;

; generated by RepRapFirmware Configuration Tool v3.1.9 on Thu Dec 03 2020 14:00:14 GMT+0300 (Москва, стандартное время)

G91 ; relative positioning

G1 S1 X1105 Y1105 Z1105 F600 ; move all towers to the high end stopping at the endstops (first pass)

G1 S2 X-5 Y-5 Z-5 F600 ; go down a few mm

G1 S1 X10 Y10 Z10 F360 ; move all towers up once more (second pass)

G1 Z-5 F6000 ; move down a few mm so that the nozzle can be centred

G90 ; absolute positioning

G1 X0 Y0 F6000 ; move X+Y to the centre -

Can you test your endstops with M119?

Has anything changed recently?