There's no command to turn on a heater directly???

-

If I set

G10 P0 S215 R215, the heater staysoff. What commands are you supposed to but in the slicer gcode to turn on the heater WITHOUT using theTcommand?I find doing

T0 P0thenT-1 P0very cumbersome just to turn on a heater. -

@gnydick M104/M109 sets temperature of the active tool, so can turn heater on and off directly, but does not deactivate tool. Using G10 to set active and standby temp of tool has been in use for a looooong time. P parameter in T commands effects whether tool change macros run, and generally not needed.

Ian

-

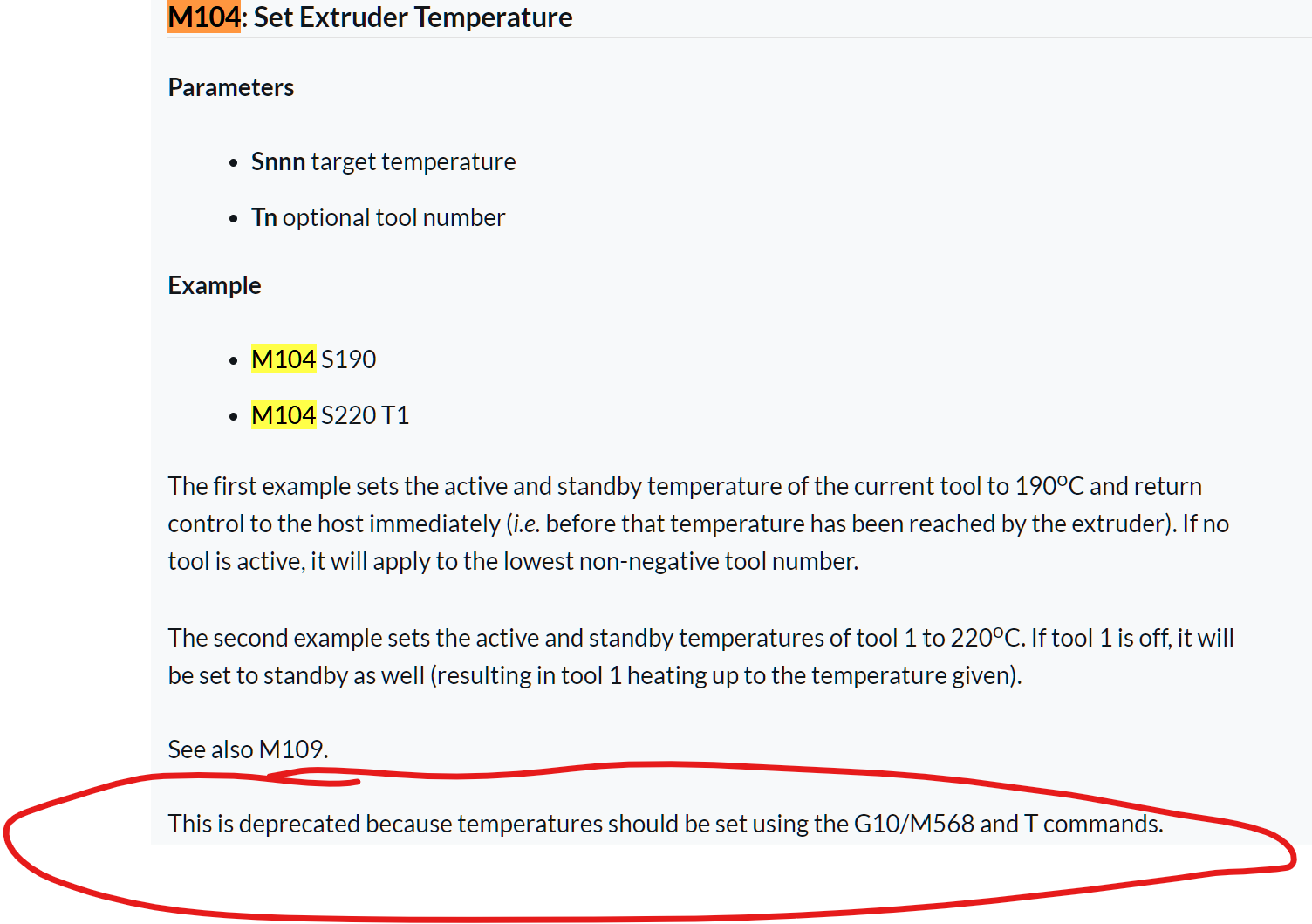

@droftarts yes, you're right, but the M commands are deprecated.

-

@gnydick I'm pretty sure they still work, though I haven't tested for a while.

Ian

-

@droftarts of course they work, they're deprecated, not deactivated. The point is, that means they're going to be removed soon and it seems like there's no replacement. I'm trying to be diligent and updating my g-code, replacing all of the deprecated stuff I know about and would prefer there to be some sort of replacement that wasn't more work.

-

There was also some talk, if I recall correctly, of cutting back on the overloads to G10.

Frederick

-

@fcwilt that sounds like a good idea to me. The fact we have standby and active temperatures seem like a snowflake when everything else needs to be toggled back and forth when something needs to change.

I'm surprised there isn't just on|off|temp for heaters. There are no slicers AFAIK that have a concept of standby, so why have it if it's not a common way? I could understand if there was some working group that was evolving g-code, was planning to support standby, and the slicers were following along too. But without the ecosystem moving forward, it's just an incompatibility

-

@gnydick With multiple tools, there has always been a requirement to have active and standby temperatures. It was introduced in RepRap firmware many years ago. Indeed my very first printer was a RepRap Pro Mendel tri-colour. At that time, and ever since, the way to set those temperatures has been via G10. But in general, slicers have never cottoned on to the fact that printers might have multiple heaters. So generally, one has to set the active and standby temperatures in the slicer start code.

I agree it's all very messy. The firmware writers want us to use G10 (although that is likely to be deprecated in the near future) but nobody has told the guys that write slicers. Or if they have, they don't want to make these changes.

But as well as turning heaters on and off, there is still a need to have tools which are currently not in use to be kept warm rather than allowed to cool completely. Hence the need for active and standby temperatures.

It's all a mess but I don't see what can be done to make everyone happy.

-

@deckingman there's no need for standby. there are tool change scripts/hooks. just like locking/unlocking the tool changer coupling, you can toggle temps up and down.

don't get me wrong, i'm not opposed to standby, just clarifying

-

@gnydick said in There's no command to turn on a heater directly???:

@deckingman there's no need for standby. there are tool change scripts/hooks. just like locking/unlocking the tool changer coupling, you can toggle temps up and down.

don't get me wrong, i'm not opposed to standby, just clarifying

True enough. One could use something like M104 Snn Tn at every tool change. The advantage of setting active and standby temperatures for all tools at the start of print is that the gcode file from the slicer only has to embed Tn commands. But I guess, one could always use the tool change macros to change temperature, instead of using active and standby.

TBH, it's all a bit of a pain with the mixing hot ends that I use. The reason being that there is only one heater shared between all tools. So standby temperatures are never used (or at least the will always be the same as the active temperature for the current tool). But, I have to set the active temperature and standby temperature for every tool, otherwise changing to a different tool (by simply sending a Tn command) will turn the heater off. So in my case, a command to turn a heater on directly would possibly negate the need for me to do that, in which case, your request gets my vote

Maybe if @dc42 does away with using G10 to set active and standby temperatures as he plans to do, he could also give some thought to mixing hot ends which only have a single heater (but I won't hold my breath on that).

-

@deckingman i hear ya. I made my own filament multiplexer with no moving parts, just a really well designed multiple input funnel that both doesn't jam and is confined enough to run flexibles through it.