Nozzle path is ok but some sections are not printed

-

I don't really have a stringing problem but I am using a 0.6mm nozzle and V6 titan aero. So less of a drool problem. 1mm retraction. Same for PLA and PETG. No z hop. No combing.

The reason I suggested lowered unretract speed is that I sometimes notice a bit of flow hesitation at line start with some filaments.

-

Are you running a direct drive setup?

Well I can only hope that all my problems will go away when I switch to the BMG LGX extruder with a Mosquito clone hot end that should show up with the next boat from China (the BMG LGX will be here next week)

I have been waiting for a while to get rid of my bowden setup and finally decided to go for it when I saw the BMG LGX. -

Just pulled the latest print off the build plate. It is definitely the best print at 1.4 mm retraction, no combing and a 0.5 mm Z hop .... but it still had some stringing on it - fairly thin stringing and I could have probably removed that with a heat gun fairly quickly.

Anybody have any suggestions about reducing drooling or is this just something that comes with a bigger nozzle that one has to live with?

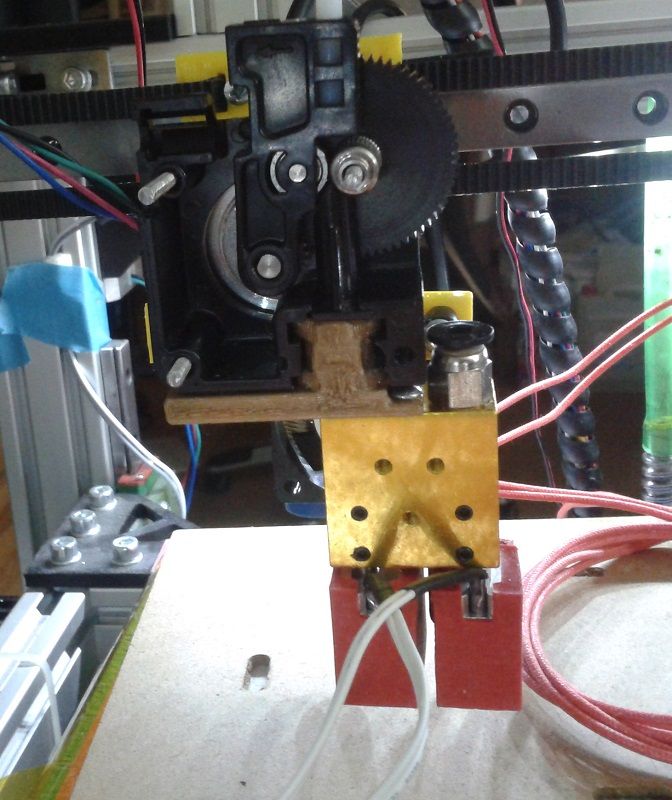

I am using a clone chimera setup with a clone Volcano hot end and a clone volcano 0.8 mm nozzle.

I would actually like to hear from somebody with a real Volcano hot end and a real Volcano nozzle and get their take on the drooling issue .... maybe it's just because it's clone stuff ..... -

@jens55

I read something about dynamic retraction, where the additional amount of filament fed back with G11 depends on the time spend between G10 and G11 (IIRC).

I think it was in the FW wishlist section.A big nozzle with anti-drool would make you rich. ( I would buy one

)

)

A long time ago I proposed to drill four 0.4mm holes close to each other instead of a single 0.8mm hole. (Only for the last mm or so)

That would result in the same cross section, but the sum of circumfences is twice as much. In my mind the circumfences are responsible for keeping the filament in.I'd use a big nozzle and long Bowden combo for Infill only, if I had a dual nozzle setup.

-

@o_lampe, the nozzle you are trying to build is already available. I don't recall who makes it but I just tripped across it a few days ago when I was looking through a suppliers catalog.

It obviously doesn't come cheap. -

@jens55

Again my idea was stolen ... the world is a bad place

[quote] It obviously doesn't come cheap.

Maybe it's not easy to build? Drilling is risky, waterjetting impossible. Maybe etching would work?

-

-

@o_lampe said in Nozzle path is ok but some sections are not printed:

A big nozzle with anti-drool would make you rich. ( I would buy one

Someplace in the back of my mind there seems to be mention of nozzles with shutoff technology possibly spring loaded. That would prevent gravity from convincing liquid filament from drooling. I think that was a system in the early days of 3D printing and was likely abandoned because of reliability issues.

I am very fuzzy on the entire thing so don't take my word for it.I'd use a big nozzle and long Bowden combo for Infill only, if I had a dual nozzle setup.

There are a lot of parameters that are linked between nozzles (at least in Cura). I don't think you can run two different sized nozzles for the same print job without custom programming of some variety.

-

@jens55 said in Nozzle path is ok but some sections are not printed:

I don't think you can run two different sized nozzles for the same print job without custom programming of some variety.

I've set it up in PrusaSlicer and sliced a big part. The result looked OK on the screen. The real advantage is, that you can use fine layerheights for the perimeters and print infill only every two or even three layers with big mama

-

@o_lampe, I realize the incredible advantages. It would nicely combine resolution and speed and would be ideal for a lot of things. I just hadn't seen it before.

It would also be a great concept with smaller nozzles if for example you could use a 0.4 mm nozzle for the interior of a model and a 0.2 mm nozzle for the outside. All of a sudden you could combine high resolution with a reasonable print time. -

@jens55

Right! But I failed with my implementation of the chimera.

The second nozzle always scratches off the fresh tracks.

Now I follow the IDEX-route. -

@jens55 3d solex nozzles aren't without their own challenges. Especially with the lower nozzle diameter extrusion sometimes seem to be pulsing, and retraction isn't easy to tune. Also, their documentation says you need to do a cold pull everytime you stop using them or their will be a lot of work. As I inherited my set of 3d solex nozzles from someone who didn't do that, I can attest that you'll need chemical cleaning in this case (ethyl acetate bath for PLA... eugh)

Their promise of high throughput holds though. I achieved roughly 36mm^3/sec on an olsson block with the 2mm 3d solex nozzle on the ultimaker it came with. -

@jens55 I agree with your analysis that the filament is oozing of it's own volition during the non print moves. I've seen it myself when experimenting with large nozzles. Things that can help are lowering the temperature if you can get away with it, and using the fastest possible non-print move speed. The former will affect the viscosity and make the filament less "runny", the latter will reduce the time that the filament is in the "oozing state".

Asymmetric retraction (greater un-retract distance) will also help but it may cause problems between print moves that do not have a significant non- print move between them.