(EDIT) Haydn Huntley 1cm magnetic bars not for enclosure (60°).

-

(edit)

See bottom!

Hi guys !

I have several post to open and I'm still lost in clouds but I finally manage to start at least one.

Haydn has shipped to me the upgrade bar for my delta (1cm thick x 40cm) and they look really good ! Despite the 6mm version I have to say that at least by hand there is not flexion. The 6mm have flexion the 1cm are totally sturdy. I have still to try different speed but I should be able to rise a little the speed without the wobbling problem.

Also, he used a new Loctite for guarantee a more hight working temperature. LOCTITE EA 9017 , +300 °F (+149 °C).

EA 9017 , +300 °F (+149 °C).

https://www.henkel-adhesives.com/my/en/product/structural-adhesives/loctite_ea_9017.html

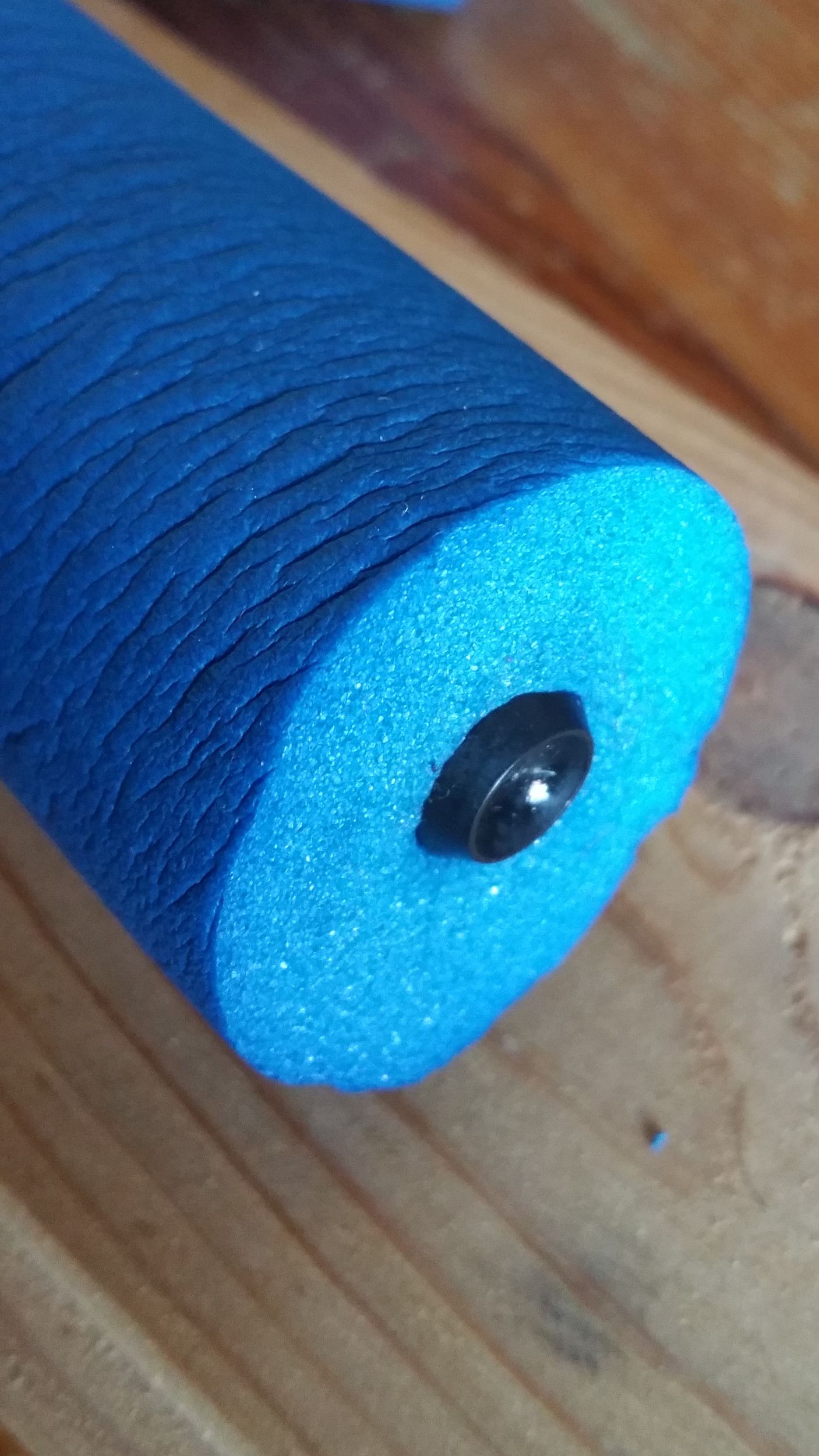

By the way I want be sure the hot chamber do not damage the glue and the Delrin (especially in long prints) so I insulated the bars with a 2.5cmx2 thick foam. (it is used for insulate the air conditioning tubes).

This insulation work great. Between the several attempts in building the hot chamber one SSR failed rising the temp in the chamber over the 100 degree (bending the filament and partially melting the extruder structure made in ASA Formfutura ; I noticed the fail from the other room because the bad smell of the SSR and I stopped the machine before the disaster ) . Well the 6mm bars didn't fail , so those ones should be even more resistant. Lesson learned , at first I settled the max temp to 140 but dint expect the chamber could pass the 100 degree , and instead can go even over .

) . Well the 6mm bars didn't fail , so those ones should be even more resistant. Lesson learned , at first I settled the max temp to 140 but dint expect the chamber could pass the 100 degree , and instead can go even over .

My delta now is build for work not over the 80 degree so I should be more than fine.

-

@giostark

Hi all !

After the first enthusiasm I managed to make my printer work a little sustained and the limit of some materials come up.

Unfortunately the only thing that make those bars not valid for be used in an enclosed environment is the Delrin. This is a good material for lots of application , it versatility lies in the good resistance at friction and the possibility to be cnc milled very good. BUT with the heat the game change.

With Haydn make we made this experiment and unfortunately it didn't succeeded.

After long print in an enclosed system with a temp of 60 Celsius (i meant 20+ hours at print) , despite using the proper lubricant changed at each print (super-lube), the Delrin start to consume making the magnet inside the bar come to touch the metal ball , finally scratching it.

I have several other ball sets so now the evolution of this project is substitute the Delrin with some metal ones. I have to ask to friends with good lathe.

I'll let you know how to the stuffs will go...