Configurator BLTouch bug

-

I mean this:

@dc42 said in Configurator BLTouch bug:

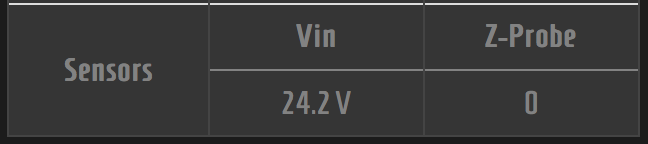

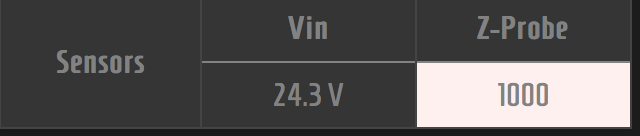

Check the Z probe reading in the web interface when the BLTouch is deployed but the pin has not been pushed up. It should be zero. If it is about 1000, then either you have not selected the correct mode in M558 (it should be P9, and you should not have the I1 parameter), or there is a bad connection between the Duet and the white wire of the BLTouch.

-

Ok I understand what you mean now but google must translate poorly what I tell you.

When there is no i1 in deployprobe.g and retractprobe.g to do auto-calibration or macros, the bltouch commands do not work.

I checked all my connector and crimp (welded) to the multimeter, no problem.

After some probing, the bltouch goes up and down which makes it blink.

//Console G-code after auto-calibration

17:45:50Déconnecté.

17:45:16Error: Z probe already triggered before probing move started

17:45:15Error: Z probe already triggered at start of probing move

Warning: Skipping grid point (-45.0, -135.0) because Z probe cannot reach it

Warning: Skipping grid point (0.0, -135.0) because Z probe cannot reach it

Warning: Skipping grid point (45.0, -135.0) because Z probe cannot reach it

17:45:14Error: Z probe already triggered at start of probing move

17:45:13Error: Z probe already triggered at start of probing move

17:45:12G32

Error: Z probe already triggered at start of probing move

17:44:20G28

17:44:08Connection établie!

17:44:06Déconnecté.

17:43:23M98 P"0:/macros/Calibration/2- Calcul Z"

Stopped at height 1.927 mm

17:42:52G30 S-1

Stopped at height 1.927 mm

//Config.g

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Thu Aug 02 2018 09:35:23 GMT+0200 (CEST); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves;*** The homed height is deliberately set too high in the following - you will adjust it during calibration.

M665 R155 L397.19 B155 H520 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; Put your endstop adjustments here, or let auto calibration find them; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80 Y80 Z80 E417.22 ; Set steps per mm

M566 X1200 Y1200 Z1200 E1200 ; Set maximum instantaneous speed changes (mm/min)

M203 X18000 Y18000 Z18000 E1200 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z1000 E1000 ; Set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E1200 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 Z0 S1 ; Set minimum Z; Endstops

M574 X2 Y2 Z2 S1 ; Set active high endstops; Z-Probe

M307 H3 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch

M558 P9 H5 F120 T6000 ; Set Z probe type to bltouch and the dive height + speeds

G31 P25 X0 Y20 Z1.927 ; Set Z probe trigger value, offset and trigger height

M557 R150 S45 ; Define mesh grid; Heaters

M305 P0 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S280 ; Set temperature limit for heater 1 to 280C; Fans

M106 P0 S0.3 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P2 S1 I0 F500 H0 T50 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic power saving

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss; Custom settings

;M591 DO C3 P2 E6.0M501

-

From your videos it looks like the probe pin is sticking. Earlier you said you had tried to repair it by taking the pin out?

Try this, put the probe into self test where it deploys and retracts the pin repeatedly and leave it running for a long while. The probe should continue indefinitely. If it gets stuck and goes into error that means that the pin is likely getting stuck. If this is the case you may need to replace the probe. The newer versions of the BLTouch are quite improved over the older style. The pins are now plastic for instance. Given the cost it may be worth just replacing it.

-

You still haven't answered my original question: is the Z probe reading shown by DWC zero (or close to zero) when the probe is not triggered?

-

I launched the selt-test at 22:44 and at 22:57 it was still running. So it works well in the void.

Yes I think I have this option to buy a newer, newer bltouch that will be the least expensive. But there is also buy the complete delta kit Duet3D Smart Effector. this will allow me to be more precise from what it says on any bed surface.

-

-

I just launched the auto calib, it was 2 probes and the sensor has increased to 1000.

G-code Console after bug sensor

23:08:49Error: Z probe already triggered before probing move started

23:08:47Error: Z probe already triggered at start of probing move

Warning: Skipping grid point (-45.0, -135.0) because Z probe cannot reach it

Warning: Skipping grid point (0.0, -135.0) because Z probe cannot reach it

Warning: Skipping grid point (45.0, -135.0) because Z probe cannot reach it

23:08:47Error: Z probe already triggered at start of probing move

23:08:46Error: Z probe already triggered at start of probing move

23:08:45Error: Z probe already triggered at start of probing move

23:08:44Error: Z probe already triggered at start of probing move

23:08:43Error: Z probe already triggered at start of probing move

23:08:43Error: Z probe already triggered at start of probing move

23:08:41Error: Z probe already triggered at start of probing move

23:08:40Error: Z probe already triggered at start of probing move

23:08:38G32

Error: Z probe already triggered at start of probing move -

it's still weird to have a 2 bltouch that does not work? it is not a problem of speed of retraction of the bltouch and or the speed of mounting of the head too slow?

in a first time this model will go?

https://www.amazon.fr/dp/B0748FJ48N/ref=cm_sw_r_cp_api_U8QzBb19A3CF4

-

I exceeded my support credit or tried to understand what I'm doing wrong? I'm still at the same point, impossible to print. I have an old-fashioned configuration solution without bltouch?

Thanks you

-

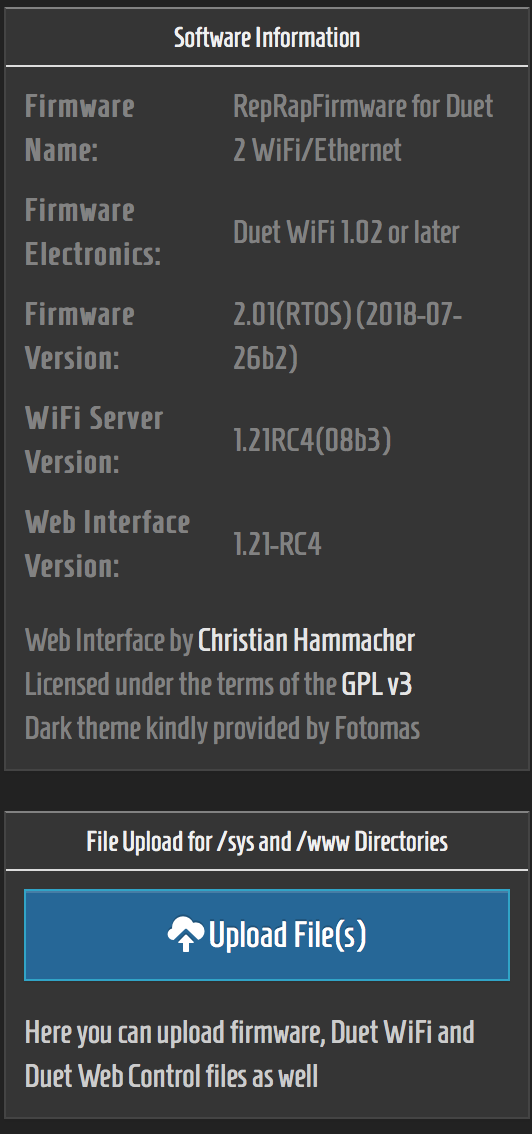

What is the correct version of the web server? Why I have 1.21 RC4 after the update?

Thank you

-

@rafb do you have the deployprobe.g and retractprobe.g files in the same file location as the config file?

-

Yes,

-

@rafb I just checked the video. When the pin is deployed does the red light turn off? If not then that’s the issue. The Red light is on when it detects the pin. When the pin is deployed it should be off since well the probe is deployed and not detected.

Could be a defective bltouch.

I saw you had another one. Does that have the same issue? If so, can you take a picture of the wiring?

Also make sure you check the wires for continuity with a DMM.

-

@rafb said in Configurator BLTouch bug:

What is the correct version of the web server? Why I have 1.21 RC4 after the update?

Thank you

You'll need to upload two more files.

You will need wifi server https://github.com/dc42/RepRapFirmware/releases/download/2.01/DuetWiFiServer-1.21.bin

And DWC https://github.com/chrishamm/DuetWebControl/releases/tag/1.22

-

@rafb said in Configurator BLTouch bug:

in a first time this model will go?

https://www.amazon.fr/dp/B0748FJ48N/ref=cm_sw_r_cp_api_U8QzBb19A3CF4

This one should work ok hopefully.

-

Hello,

Here I am again, always with my problems of bltouch. I will not have a new one because it is holidays and if I order in China, there is a delay of 2 weeks!I would like to tell you that I have already managed to print after a complete probing with the bltouch which does not work for the moment.

The config M558 was P5 H5 F120 T6000

Due to a problem I can not remember, I could not print anymore. After I got lost in the lines of code that I do not understand then I made the update under your advice and here I am again.

DC42, I am updating it and I may be able to give you the information you need with this great new web interface. I am not selling the firmware because I can not print but I have no doubt to achieve one day (with or without new bltouch, see even your sensor.

So tell me where and how to find DWC.Phaedrux, thank you for your advice although the delta printer is your forte. I made the update very quickly thanks to you and this ultra simple interface when we understand and we are well helped.

I have the impression that the problem is actually bltouch but especially a bad code code M558 for these old bltouch.

As I told you if I run a self-test macro it works perfectly for 15 minutes.I retest with this new update and change the parameter M558 P9 H10 F120 T10000 and probing is more point but there is always a time when the bltouch it is in error (flashes).

here are my files.g

I thank you again for the help already done and I hope to be quite clear (with google trad) to finally launch quality print.

A +

Config.g

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Thu Aug 02 2018 09:35:23 GMT+0200 (CEST); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves;*** The homed height is deliberately set too high in the following - you will adjust it during calibration.

M665 R155 L397.19 B155 H522 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; Put your endstop adjustments here, or let auto calibration find them; Network

M550 PTEVO LM ; Set machine name

M551 PSpiral-2321 ; Set password

M552 S1 ; Enable network

M587 S"TARM" P"Tino-Ant-Marj-Raf@34" ; Configure access point. You can delete this line once connected

M586 P0 S1 ; Enable HTTP

M586 P1 S1 ; Enable FTP

M586 P2 S1 ; Enable Telnet; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80 Y80 Z80 E417.22 ; Set steps per mm

M566 X1200 Y1200 Z1200 E1200 ; Set maximum instantaneous speed changes (mm/min)

M203 X18000 Y18000 Z18000 E1200 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z1000 E1000 ; Set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E1200 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 Z0 S1 ; Set minimum Z; Endstops

M574 X2 Y2 Z2 S1 ; Set active high endstops; Z-Probe

M307 H3 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch

M558 P9 H10 F120 T10000 ; Set Z probe type to bltouch and the dive height + speeds

G31 P25 X0 Y20 Z0.290 ; 1.927 Set Z probe trigger value, offset and trigger height

M557 R150 S45 ; Define mesh grid; Heaters

M305 P0 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S280 ; Set temperature limit for heater 1 to 280C; Fans

M106 P0 S0.3 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P2 S1 I0 F500 H0 T50 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic power saving

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss; Custom settings

;M591 DO C3 P2 E6.0M501

Bed.g

; bed.g

; called to perform automatic delta calibration via G32

;

; generated by RepRapFirmware Configuration Tool on Thu Aug 02 2018 09:35:23 GMT+0200 (CEST)

M561 ; clear any bed transform

G28 ; home all towers

M190 S60

;M98 Pdeployprobe.g; déployer sonde mécanique de Z

; Probe the bed at 6 peripheral and 6 halfway points, and perform 6-factor auto compensation

; Before running this, you should have set up your Z-probe trigger height to suit your build, in the G31 command in config.g.

G30 P0 X0 Y132.28 H0 Z-99999

G30 P1 X121 Y69.86 H0 Z-99999

G30 P2 X129.9 Y-75 H0 Z-99999

G30 P3 X0 Y-150 H0 Z-99999

G30 P4 X-125.9 Y-75 H0 Z-99999

G30 P5 X-121 Y69.86 H0 Z-99999

G30 P6 X0 Y59.15 H0 Z-99999

G30 P7 X56.09 Y32.38 H0 Z-99999

G30 P8 X64.95 Y-37.5 H0 Z-99999

G30 P9 X0 Y-75 H0 Z-99999

G30 P10 X-64.95 Y-37.5 H0 Z-99999

G30 P11 X-56.09 Y32.38 H0 Z-99999

G30 P12 X0 Y0 H0 Z-99999 S6

; Use S-1 for measurements only, without calculations. Use S4 for endstop heights and Z-height only. Use S6 for full 6 factors

; If your Z probe has significantly different trigger heights depending on XY position, adjust the H parameters in the G30 commands accordingly. The value of each H parameter should be (trigger height at that XY position) - (trigger height at centre of bed)

;M98 Pretractprobe.g; rétracter la sonde mécanique Z

G29Deployprobe.g

; deployprobe.g

; called to deploy a physical Z probe

;

; generated by RepRapFirmware Configuration Tool on Thu Aug 02 2018 09:35:23 GMT+0200 (CEST)

;M280 P3 S160 I1

M280 P3 S10 I1Retractprobe

; retractprobe.g

; called to retract a physical Z probe

;

; generated by RepRapFirmware Configuration Tool on Thu Aug 02 2018 09:35:23 GMT+0200 (CEST)

M280 P3 S90 I1 -

@rafb said in Configurator BLTouch bug:

Hello,

Here I am again, always with my problems of bltouch. I will not have a new one because it is holidays and if I order in China, there is a delay of 2 weeks!I would like to tell you that I have already managed to print after a complete probing with the bltouch which does not work for the moment.

The config M558 was P5 H5 F120 T6000

Due to a problem I can not remember, I could not print anymore. After I got lost in the lines of code that I do not understand then I made the update under your advice and here I am again.

DC42, I am updating it and I may be able to give you the information you need with this great new web interface. I am not selling the firmware because I can not print but I have no doubt to achieve one day (with or without new bltouch, see even your sensor.

So tell me where and how to find DWC.Phaedrux, thank you for your advice although the delta printer is your forte. I made the update very quickly thanks to you and this ultra simple interface when we understand and we are well helped.

I have the impression that the problem is actually bltouch but especially a bad code code M558 for these old bltouch.

As I told you if I run a self-test macro it works perfectly for 15 minutes.I retest with this new update and change the parameter M558 P9 H10 F120 T10000 and probing is more point but there is always a time when the bltouch it is in error (flashes).

here are my files.g

I thank you again for the help already done and I hope to be quite clear (with google trad) to finally launch quality print.

A +

Config.g

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Thu Aug 02 2018 09:35:23 GMT+0200 (CEST); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves;*** The homed height is deliberately set too high in the following - you will adjust it during calibration.

M665 R155 L397.19 B155 H522 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; Put your endstop adjustments here, or let auto calibration find them; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80 Y80 Z80 E417.22 ; Set steps per mm

M566 X1200 Y1200 Z1200 E1200 ; Set maximum instantaneous speed changes (mm/min)

M203 X18000 Y18000 Z18000 E1200 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z1000 E1000 ; Set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E1200 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 Z0 S1 ; Set minimum Z; Endstops

M574 X2 Y2 Z2 S1 ; Set active high endstops; Z-Probe

M307 H3 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch

M558 P9 H10 F120 T10000 ; Set Z probe type to bltouch and the dive height + speeds

G31 P25 X0 Y20 Z0.290 ; 1.927 Set Z probe trigger value, offset and trigger height

M557 R150 S45 ; Define mesh grid; Heaters

M305 P0 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S280 ; Set temperature limit for heater 1 to 280C; Fans

M106 P0 S0.3 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P2 S1 I0 F500 H0 T50 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic power saving

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss; Custom settings

;M591 DO C3 P2 E6.0M501

Bed.g

; bed.g

; called to perform automatic delta calibration via G32

;

; generated by RepRapFirmware Configuration Tool on Thu Aug 02 2018 09:35:23 GMT+0200 (CEST)

M561 ; clear any bed transform

G28 ; home all towers

M190 S60

;M98 Pdeployprobe.g; déployer sonde mécanique de Z

; Probe the bed at 6 peripheral and 6 halfway points, and perform 6-factor auto compensation

; Before running this, you should have set up your Z-probe trigger height to suit your build, in the G31 command in config.g.

G30 P0 X0 Y132.28 H0 Z-99999

G30 P1 X121 Y69.86 H0 Z-99999

G30 P2 X129.9 Y-75 H0 Z-99999

G30 P3 X0 Y-150 H0 Z-99999

G30 P4 X-125.9 Y-75 H0 Z-99999

G30 P5 X-121 Y69.86 H0 Z-99999

G30 P6 X0 Y59.15 H0 Z-99999

G30 P7 X56.09 Y32.38 H0 Z-99999

G30 P8 X64.95 Y-37.5 H0 Z-99999

G30 P9 X0 Y-75 H0 Z-99999

G30 P10 X-64.95 Y-37.5 H0 Z-99999

G30 P11 X-56.09 Y32.38 H0 Z-99999

G30 P12 X0 Y0 H0 Z-99999 S6

; Use S-1 for measurements only, without calculations. Use S4 for endstop heights and Z-height only. Use S6 for full 6 factors

; If your Z probe has significantly different trigger heights depending on XY position, adjust the H parameters in the G30 commands accordingly. The value of each H parameter should be (trigger height at that XY position) - (trigger height at centre of bed)

;M98 Pretractprobe.g; rétracter la sonde mécanique Z

G29Deployprobe.g

; deployprobe.g

; called to deploy a physical Z probe

;

; generated by RepRapFirmware Configuration Tool on Thu Aug 02 2018 09:35:23 GMT+0200 (CEST)

;M280 P3 S160 I1

M280 P3 S10 I1Retractprobe

; retractprobe.g

; called to retract a physical Z probe

;

; generated by RepRapFirmware Configuration Tool on Thu Aug 02 2018 09:35:23 GMT+0200 (CEST)

M280 P3 S90 I1 -

@rafb, DWC is short for Duet Web Control. You can find it along with the firmware files at https://github.com/dc42/RepRapFirmware/releases. Chrishamm sometimes has a later version available at https://github.com/chrishamm/DuetWebControl/.

-

Under the advice of Phaedrux, I installed DWC https://github.com/chrishamm/DuetWebControl/.

I would like to know with which parameter I can play so that the bltouch does not put it in default (Blink)

When my printer is at home, I measure 517mm from the bed to my nozzle. So I change M665 H522 for the DWC shows me 517 when it is at home. It's correct?

I also change M558 P9 H10 and I observed that it was more probing.

Do you have any suggestions for modifying M558?thank you

-

@rafb said in Configurator BLTouch bug:

When my printer is at home, I measure 517mm from the bed to my nozzle. So I change M665 H522 for the DWC shows me 517 when it is at home. It's correct?

Yes if you are using the standard homedelta.g file, which lowers the effector by 5mm after homing so that the nozzle can be safely centred.

I also change M558 P9 H10 and I observed that it was more probing.

Do you have any suggestions for modifying M558?

The H parameter defines the height at which probing starts. So a higher H parameter means probing takes longer (because the probe takes longer to reach the bed), but that it is more tolerant of calibration being a long way out. So we recommend that you used a high H value for initial calibration. Once you have performed calibration and copied the new values into your M665 and M666 commands in config.g, you can reduce the H parameter so that probing takes less time.