Hi guys,

I'm playing with my new extruder and would like to know how much it extrudes in a real print.

Is it possible to display extrusion volume in DWC? Printspeed, layerheight and layerwidth? should be available for calculations.

I extruded in free air to get ballpark numbers, but real life is different.

Best posts made by o_lampe

-

Displaying current extrusion volume possible?posted in Duet Web Control wishlist

-

RE: Music skipping beats after firmware update (3.4.0beta6)posted in Tuning and tweaking

@gtaman

It's actually the same:- create a global variable blockDaemon

- set global.blockDaemon = true at the start of the M300 file

- set global.blockDaemon = false at the end

Then anyone using Daemon.g for real can add these lines

while global.blockDaemon = true G4 S1000 -

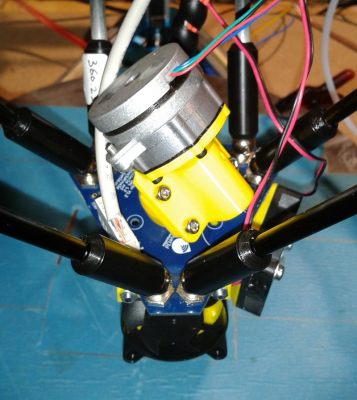

RE: Hollow shaft extruderposted in General Discussion

Had my first simpleFOC project running today. It was an old brushless gimbal controller without encoders and with 8bit mcu.

I was able to control two motors independently and relatively smooth (USB power only)

The atmega328 was also at it's limit, but I'm now confident it will work well with the right mcu. -

RE: External stepper drivers (TB6600) on duet 2 wifiposted in Using Duet Controllers

@m0ck1nj

Check the TB6600 datasheet. If it is OK with 3.3V signals on step, dir, enable you can wire it directly.

If it needs differential signals or 5V you can use the much cheaper expansion breakout board -

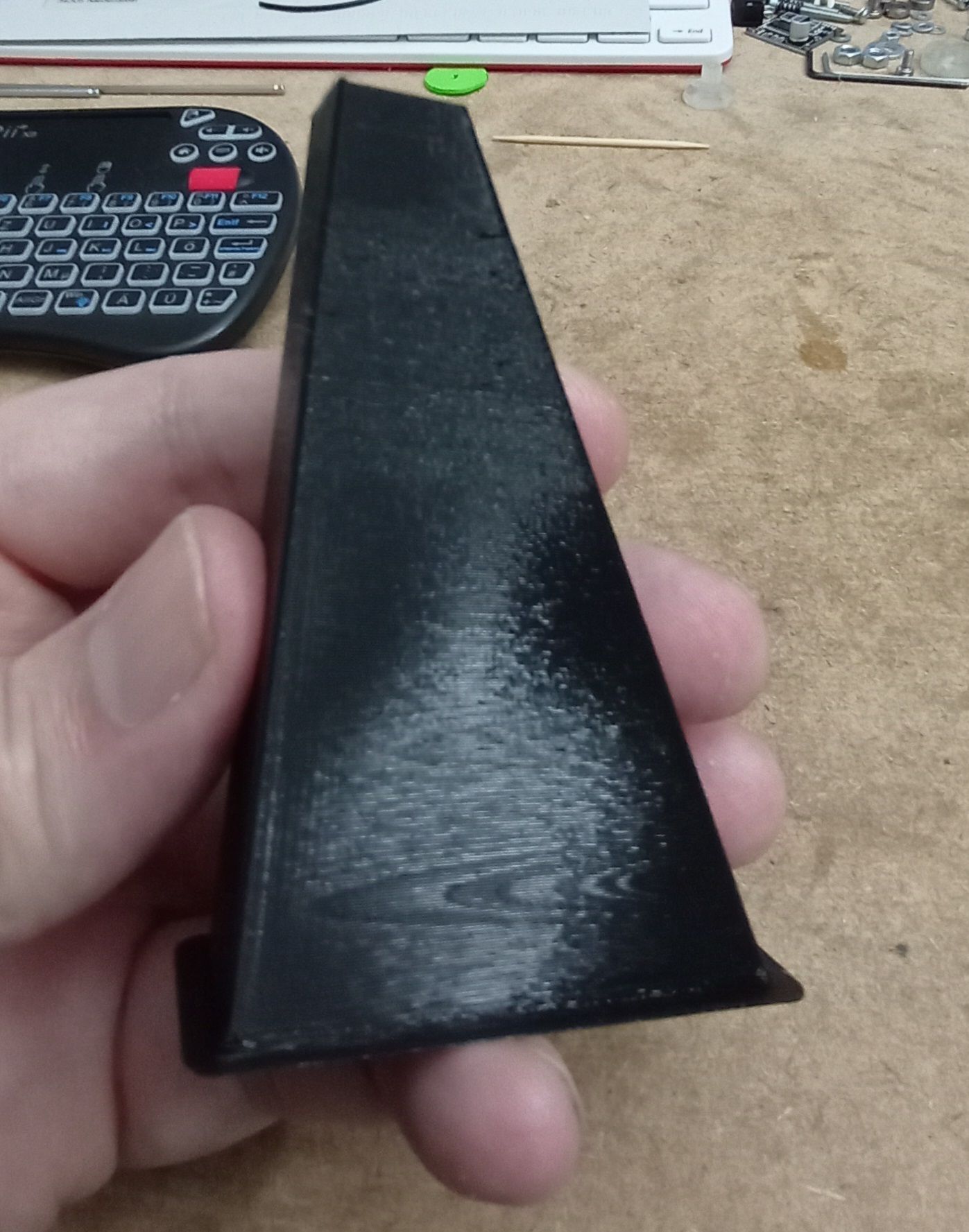

RE: Hollow shaft extruderposted in General Discussion

First print today

Instead of a benchy, I tried the extruder-woodgrain test. Yes there is some, but hardly visible. The corners were sharp and even, that was a relieve. The close loop PID setting are quite soft, so I expected worse...

At the top third, the printspeed got so low, that the filament overheated. 10°C less temp and it was nice and shiny again.

-

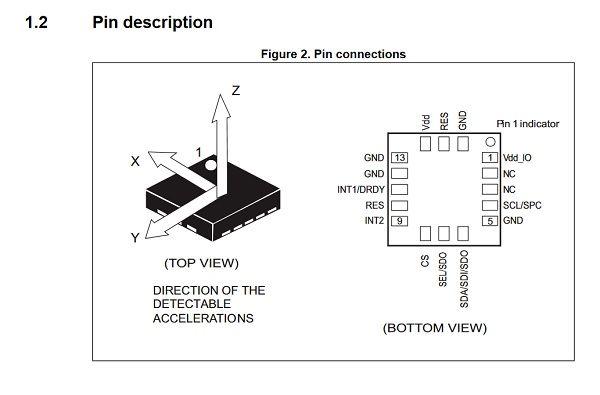

RE: Accelerometer Usageposted in Beta Firmware

According to this picture

- positive X goes to the right

- positive Y goes to the back

- positive Z goes up

-

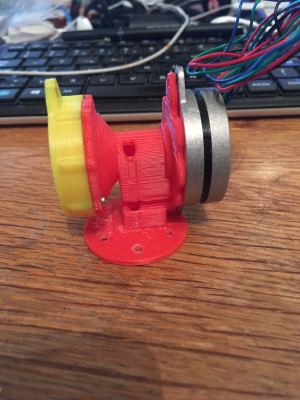

RE: Smart Effector including toolboard-capabilities?posted in Smart effector for delta printers

@dc42 said in Smart Effector including toolboard-capabilities?:

It's clear to me that the Orbiter could not be used with a Smart Effector made to the current dimensions. We would need to increase the rod spacing to at least 80mm in order to accommodate the various parts of the extruder. We are looking into this, however it would make it unsuitable for the smaller delta printers.

Hi dc42,

I just stumbled across this thread and wanted to guide you back to 2016 , when we discussed the cycloidal direct drive. (I still have it laying around)

I've made an 45 degree adapter for it, that suited the smart effector pretty well.

Another way to mount it, was the split motor/gearbox idea.

I could try to reuse my motor and design a BMG-drive for the Smart effector?

-

Display current back EMF for tuningposted in Duet Web Control wishlist

Hi devs,

based on the "extrusion volume" thread, I also think a back EMF calculator as DWC plugin would be helpful for tuning.

The required parameters are almost completely known for the calculation. It only misses coil resistance and inductivity (AFAIK)Since my Duet boards run on their own network, I don't have access to the EMF calculator at reprapfirmware.org

If we could integrate it as plugin and use 'live' values from the current object model/gcode file, we'd have a nice tuning tool

-

RE: Add 'pre-retract' and 'post-retract'posted in Firmware wishlist

@nikscha I like the idea. It's like the tool-change macros.

But there is also a problem when you retract / unretract within a toolchange.

Maybe you can solve your problem by renaming G10/G11 to G10.1 and G11.1 via postprocessing. Then you need only one macro for retraction (which also contains the real G10 move) -

RE: HELP! New Cast Alum. Bed doesn't seem to AutoMeshLevelposted in General Discussion

One thing not mentioned by anyone is the G31 probe offset. Are you sure it's OK?

Latest posts made by o_lampe

-

RE: Any possibility to implement keep out area on Duet 2?posted in Firmware wishlist

@oliof ESP32 and RP2040 modules have external (SPI?) flash. So I thought, it might not be too strange to mention.

-

RE: duet for 4+ axis latheposted in CNC

@yoshimitsuspeed Yes, for threading you could turn the spindle into a sync'd axis and with 2^31 microsteps you could run it for days before reaching the fence

I've done some CNC milling with Duet boards in the past and it was already nerve wracking sometimes. Using it for a lathe would be even less convenient IMHO.

I wouldn't want to do that on daily bases or for earning money. -

RE: Any possibility to implement keep out area on Duet 2?posted in Firmware wishlist

@dc42 I thought of flashing the required module to ROM during the first startup? ( like it does during an FW-update)

On later startups the FW would only check if the kinematic model has changed (which is rarely the case)Another option might be a SPI flash ROM extension board connected to the PanelDue port?

But that would require extra work for the FW department and users could no longer use Panel Due. -

RE: Any possibility to implement keep out area on Duet 2?posted in Firmware wishlist

@GeneRisi I was wondering, if the Duet dev team could change the way kinematic models are implemented?

Wouldn't it be nice to have a kinematics-folder on SD-card and load the required kinematic model at startup? -

RE: Red & Black 80W CO2 - Stepper Motor Replacement Optionsposted in Laser Cutters

@shenbiand4 I found a thread about your motor on lightburn-forum.

The only confusing info about a replacement motor was the required shaft diameter.

Make sure, you measure your motors shaft, before you buy. NEMA23 steppers can be found with 5 ,6, 8, 10mm shaft and also 1/4 or 3/8 inch shaft.

If you pick the wrong one, you'll have to look for the right pulley for your belt.

All other requirements are pretty common, like 1.8 degree, 4-wire, 2.8A and 56mm motor length as you've already noted. Can't go wrong there.The Oyo motors you've linked are almost identical, except for the D-shaft and wire length. I'd go for D-shaft, if I had to choose.

-

RE: shutting down a servo?posted in General Discussion

A humming servo is a regular thing, when it doesn't reach the desired angle.

It happens, even when the servo arm is within the boundaries of the internal gears, but it's no problem then. (unless your setup requires too much torque)

You could try one thing, for peace of mind:- command the servo 5 degree or microsecond past the point you want to reach (whichever you prefer)

- wait a little while for the arm to reach the position (eg. G4 P200 ; waits 200milliseconds)

- move 5 back

With that trick, you'll overcome the backlash of the internal potmeter and it will be quiet

Maybe have to adapt to different angles/microseconds for your specific servo -

RE: Constant motor noise after a move, since firmware updateposted in Duet Hardware and wiring

@jwilo IIRC there was a speed threshold where the driver automatically switched from stealthChop to spreadCycle and vice versa.

When I updated to 3.4.6, I've made no changes to M569 and it still behaves the same. -

RE: on-off control of router using M3 and M5 g-code commandsposted in CNC

@woodcarver I'm wondering if you have to switch the Duet to CNC-mode to allow M3 and M5 commands?

-

RE: difficulty configuring a custom 2-axis CNCposted in Duet Hardware and wiring

@jbeck With microswitches as endstops, you have to check if they are NO (normally open) or NC (normally closed)

If they are NO, you have to invert the endstop logic with an "!" like that:; Endstops M574 X1 S1 P"!xstop"I remember vaguely, there is a way to check endstop status from DWC, but it's early sunday morning....

If you check them and they are already triggered before they are hit, you have to invert. -

RE: Delta mechanism as routerposted in CNC

@EasyTarget Maybe I chose the wrong words, but with engraving I meant using a small router and a chisel. Their tips are tiny and they rotate slightly offcenter.

The load to the effector would be light enough. You can also engrave metal and fumes or dust are no problem.