Help configuring vers 3.3

-

Hello everyone,

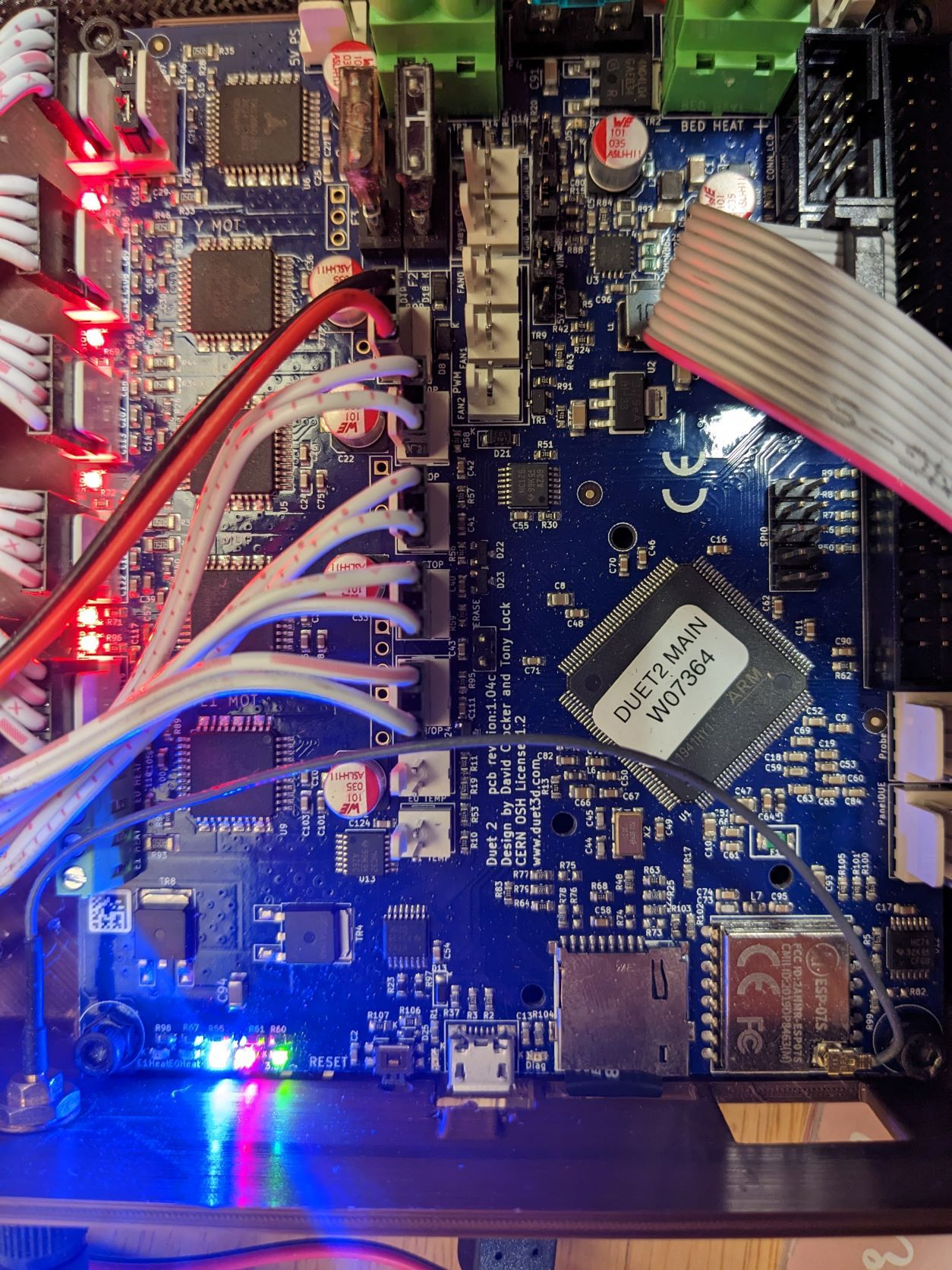

I recently acquired an older model MPCNC from a friend and foolishly updated the firmware and lost everything.

I have zero experience with 3d printing but my day job is programming and setting up HAAS and Fanuc cnc milling machines for an aerospace company. Somehow i figured out how to configure the drive and endstops for the x ( 0 and 3 ) and the y (1 and 4). Everything homes correctly but when i try to run a simple program the router doesn't read the x and y correctly and goes up and down on the z. any help is appreciated. I found doing the research to be extremely difficult trying to sort through all the versions so just posting current config.g and homeall files would be extremly helpful.; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.15 on Tue Jan 24 2023 21:08:30 GMT-0500 (Eastern Standard Time) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M550 P"MPCNC" ; set printer name ;THIS IS A SLOPPY AND PROB WRONG CONFIG FILE ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forward M569 P1 S0 ; physical drive 1 goes REVERSE M569 P2 S0 ; physical drive 2 goes REVERSE M569 P3 S0 ; physical drive 3 goes REVERSE M569 P4 S1 ; physical drive 4 goes forward M584 X0:3 Y1:4 Z2 ; configure drive mapping M350 X16 Y16 Z16 ; configure microstepping with interpolation M92 X100.00 Y100.00 Z400.00 ; set steps per mm M566 X900.00 Y900.00 Z300.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z800.00 U900 V900.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z40.00 U500.00 V500.00 ; set accelerations (mm/s^2) M906 X800.00 Y800.00 Z800.00 ; set motor currents (mA) M84 S10 ; Disable motor idle current reduction ; Axis Limits M208 X0 Y0 Z-100 U0 V0 S1 ; set axis minima M208 X770 Y260 Z200 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop+e0stop" ; configure endstop M574 Y1 S1 P"ystop+e1stop" ; configure endstop M574 Z1 S1 P"!zstop" ; configure endstop ; Z-Probe M558 P5 C"zstop" H5 F120 T3000 ; Z probe connected to Duet 2 Z endstop input ; Heaters M140 H-1 ; Disable heated bed ; Tools ; Tools M563 P0 S"Router" R0 ; Define the router as tool 0 M453 ; Set CNC Mode M575 P1 S1 B57600 ; Enable PanelDUE at 57600 BPSPLEASE EXCUSE MY SLOPPY CODING

How i think a program should startG20 G90 G0X1.3848Y1.0000 G1Z-0.0400F10.0 X1.3846Y0.9931F35.0 X1.3841Y0.9863 X1.3832Y0.9795

-

@jmorganmkm said in Help configuring vers 3.3:

but when i try to run a simple program the router doesn't read the x and y correctly and goes up and down on the z

Do you mean that X and Y don't move, but Z does? Or something else?

After you run homing and before you run your file, does Duet Web Control show X, Y and Z as all homed (axis buttons blue instead of orange)?

Please post your homeall.g file.

-

@dc42

I think the machine homes correctly and I am able to jog the machine in the correct axis and distance. The second file i uploaded was the start of a snowflake engrave but instead of lowering z to -.04 and moving the xy it instead lowers z to -.04 and than raises it again, moves to another position and drops z again, raises it and moves xy.

My next idea is to put it into cartesian mode but i thought that was default. here is my homeall; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Tue Apr 20 2021 01:19:12 GMT-0600 (Mountain Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-767 Y-945 F1800 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X10 Y10 F6000 ; go back a few mm G1 H1 X-20 Y-20 F360 ; move slowly to X and Y axis endstops once more (second pass) G1 H1 Z-95 F360 ; move Z down stopping at the endstop G90 ; absolute positioning G92 Z0.5 ; set Z position to axis minimum (you may want to adjust this) ; Uncomment the following lines to lift Z after probing G91 ; relative positioning G1 Z5 F100 ; lift Z relative to current position G90 ; absolute positioning -

@jmorganmkm have you confirmed that you are running firmware 3.3 and that it is in CNC mode? Send M115 to check the firmware version, and send M450 to check the printer mode.

Your file sends X and Y coordinates without a previous G1 on the same line. That's supported by RRF in CNC mode but not in FDM mode.

-

@dc42

I just confirmed it is in cnc mode and 3.3.

I'm going to try adding more g1's to the program and see what happens -

@jmorganmkm I found this item in the bug fix list in version 3.4.0 at https://github.com/Duet3D/RepRapFirmware/wiki/Changelog-RRF-3.x#reprapfirmware-340 (search for CNC to find it):

In CNC and laser mode it is permitted to omit G0/G1 at the start of a line of GCode and just provide parameters, provided that the previous command was G0 or G1. However, only parameter letters that were present in that previous G0/G1 command were recognised.

So this is a bug in 3.3 which is fixed in 3.4.