New firmware 2.03RC2 available

-

Working fine CoreXY with 3 steppers on X, 3 on Y, 3 on Z and one E. As seen on 3D Sweden Meetup. Though still same error about "homing file not found" after first reset. Tried printing at 300mm/s and travel at 600mm/s with 80 steps/mm.

-

@dc42

to not get confused: They are split macros to be able to call the actual homex-movement.g either direct and only for homex.g or to call it within homeall.g1st) homex.g

; called to home the x axis

; for general reference see https://duet3d.dozuki.com/Wiki/Gcode#main

;M291 P"Homing x?" R"Make sure fly-shuttle cannot crash!" S3 ; intentionally?

; change endstop/homing behaviour

M564 H0 S0 ; S1 = enable axis limits, H1 = NOT allow movement of axes that have not been homedM98 P"home-zhop-plus.g" ; call P".g" submacro; see https://duet3d.dozuki.com/Wiki/Gcode#Section_M98_Call_Macro_Subprogram

M98 P"homex-movement.g" ; call P".g" submacro; see https://duet3d.dozuki.com/Wiki/Gcode#Section_M98_Call_Macro_Subprogram

M98 P"home-zhop-minus.g" ; call P".g" submacro; see https://duet3d.dozuki.com/Wiki/Gcode#Section_M98_Call_Macro_Subprogram

; change endstop/homing behaviour

M564 H1 S1 ; S1 = enable axis limits, H1 = NOT allow movement of axes that have not been homed2nd) homex-movement.g

; actual homex-movement

; for general reference see https://duet3d.dozuki.com/Wiki/Gcode#mainG54 ; use 1st machine coordinate-system, see https://duet3d.dozuki.com/Wiki/Gcode#Section_G54_to_G59_3_Select_coordinate_system

M400 ; Finishes all current moves and and thus clears the buffer

;M913 X50 ; set specified motors to 0-100% of their normal current specd in the config.g

G1 H1 X-705 F1250 ; move "quickly" to specified axis endstop and stop there (first pass), make sure it is slow enough to have some place left after hitting endstop to break to halt before crashing

G1 X10 F550 ; go back a few mm to make sure the trigger can "untrigger"!

G4 P100 ; dwell for time in P_ milliseconds or S_ seconds

M400 ; Finishes all current moves and and thus clears the buffer

G1 H1 X-705 F65 ; move slowly to specified axis endstop once more (second pass)G1 X0 ; be sure to be at 0

; zero out also G55-2ndcsys

G10 L20 P2 X0 ; set P1=G54-1stcsys, P2=G55-2nd-csys, ...G1 X20 F1500 ; move inwards a few mm

G92 X0 ; set axis to 0M400 ; Finishes all current moves and and thus clears the buffer

;M913 X100 ; set specified motors to 0-100% of their normal current specd in the config.g

M117 Homed P1/G54 in X ; put out message to console/user

-

@typqxq said in New firmware 2.03RC2 available:

Though still same error about "homing file not found" after first reset.

What is the exact error message?

-

Thank you for adding the option to set the minimum movement speed! Now i can work all axes in mm.. However it seems like there is also a minimum limit of 1mm/s applied to G0 moves as well? In my config file I set this:

M203 X2500 Y2500 Z20 E10000 I1

If I send G1 Z5 F20; the commanded speed is correct.

If I send G0 Z5; The max feedrate set in M203 is not honoured and it commands 1mm/s or F60.

This doesn't really bother me except that all of the motion buttons on the PanelDue and Webcontrol send a G0.. Or am I missing something?? -

Hi , Wifi connected IP address provided , but the IP address is not working , pls help

-

@milan WiFi module is connected to access point MMM, IP address 192.168.43.250

-

@ben_van said in New firmware 2.03RC2 available:

Thank you for adding the option to set the minimum movement speed! Now i can work all axes in mm.. However it seems like there is also a minimum limit of 1mm/s applied to G0 moves as well? In my config file I set this:

M203 X2500 Y2500 Z20 E10000 I1

If I send G1 Z5 F20; the commanded speed is correct.

If I send G0 Z5; The max feedrate set in M203 is not honoured and it commands 1mm/s or F60.

This doesn't really bother me except that all of the motion buttons on the PanelDue and Webcontrol send a G0.. Or am I missing something??Are you running the machine in CNC mode (using M453) or in the default FDM mode? In CNC mode, G0 should use the maximum feed rate. In FDM mode, it uses the same feed rate as G1 commands.

-

@milan said in New firmware 2.03RC2 available:

Hi , Wifi connected IP address provided , but the IP address is not working , pls help

Is this specific to firmware 2.03RC2, or does it happen in 2.02 as well? If it isn't specific to 2.03RC2, please create a separate thread for your issue.

-

There are some known issues with firmware 2.03RC2 on CNC machines when using workplace coordinates, so please do not use workplace coordinates with this release.

-

@dc42 said in New firmware 2.03RC2 available:

@ben_van said in New firmware 2.03RC2 available:

Thank you for adding the option to set the minimum movement speed! Now i can work all axes in mm.. However it seems like there is also a minimum limit of 1mm/s applied to G0 moves as well? In my config file I set this:

M203 X2500 Y2500 Z20 E10000 I1

If I send G1 Z5 F20; the commanded speed is correct.

If I send G0 Z5; The max feedrate set in M203 is not honoured and it commands 1mm/s or F60.

This doesn't really bother me except that all of the motion buttons on the PanelDue and Webcontrol send a G0.. Or am I missing something??Are you running the machine in CNC mode (using M453) or in the default FDM mode? In CNC mode, G0 should use the maximum feed rate. In FDM mode, it uses the same feed rate as G1 commands.

I am running the machine in laser mode (M452). Previously when i was using older firmware, and had the Z axis in steps per micron, G0 moves would take the max feedrate set in M203. They do also on this release, however only for the X and Y axis, not Z.

-

That's odd because X Y and Z should be treated in exactly the same way. Please post your config.g file.

-

Anyone having issues with babystepping not working? On rc2 with dwc 1,23/2.0 and I can't step down but I've never tried on the stable. Will roll back after this print and check.

Edit: just read that M208 is stopping it from going below Z0. What a strange limit to have. Well then it's not a firmware issue atleast since I have M208 set to Z0.

-

@dc42

Just did a few tests..

Everything works as expected for G0 moves if the feedrate set in M203 is higher than 60mm/min. If I set the max feedrate lower than 60mm/min in M203 for any axes, G0 moves will still request a speed of 60mm/min.

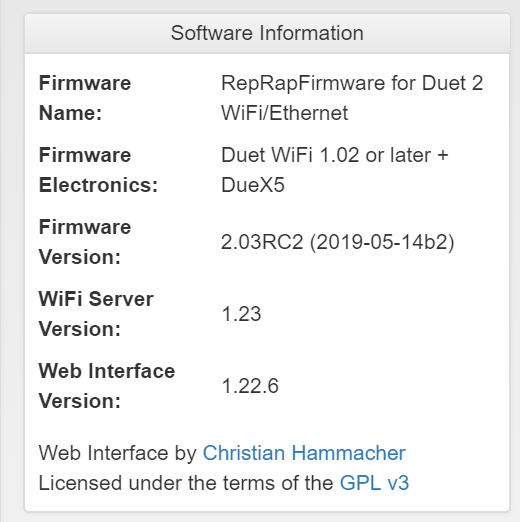

Setup:- Duet 2 Wifi

- Web control 2.0.0-RC6

- Wifi server 1.23

- PanelDue 7.0i 1.23.2

Config.g is as follows:

; General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves; Network

M550 P ; Set machine name

M552 S1 ; Enable network

M587 S"" P"" ; Configure access point. You can delete this line once connected

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S0 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwardsM350 X256 Y256 Z256 I0 ; Configure microstepping without interpolation

M350 E64 I1 ; Configure microstepping with interpolation

M92 X3769 Y2094 Z256000 E53 ; Set steps per mm //// XY:mm, Z:mm, E:ulM566 X45 Y45 Z3 E200 ; Set maximum instantaneous speed changes (mm/min)

M203 X2500 Y2500 Z20 E10000 I1 ; Set maximum speeds (mm/min), and I (minimum speed)

M201 X2000 Y2000 Z10 E2000 ; Set accelerations (mm/s^2)

M906 X500 Y500 Z500 E500 I75 ; Set motor currents (mA) and motor idle factor in per cent

M84 S60 ; Set idle timeout; Axis Limits

M208 X-75 Y-48 Z-30 S1 ; Set axis minima

M208 X0 Y0 Z0 S0 ;Set axis maxima; Heaters

M140 H0 ; heater 0 is the bed

M305 P0 S"Vessel heater" T100000 B3950 R4700 C0;

M307 H0 A26.6 C73.9 D1.0 B0 S0.2 V12.6 ; set process parameters for heater 1, use PID, and limit heater 1 PWM to 20%

M143 H0 S45 ; Set temperature limit for heater 0 to 50C; Fans

M106 P0 S0 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S0.5 I0 F500 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P2 S0.5 I0 F500 H-1 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned off; Automatic saving after power loss is not enabled

; Custom settings

M106 P0 I-1 ; Disable the Fan

M106 P2 I-1 ; Disable the Fan

M452 P22 R255 F8000 ; Set the printer into Laser mode P(Fan) R(Max power value for S command with M3) F(PWM frequency used)

M564 S1 H1 ; H0 allow movement before homing, S1 limit motion between axis boundaries

M574 X2 Y1 Z2 S0 ; Set active low endstops (for some reason never set z properly in configuration; Tools

M558 P0; disable the z probe

M563 P0 S"Laser"

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

G10 P0 X0 Y0;M563 P1 S"Camera"

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

G10 P1 X-1 Y-0.6;M563 P2 D0 S"Extruder" ; Define tool 2

G10 P2 R0 S0 ; Set initial tool 2 active and standby temperatures to 0C

G10 P2 X0 Y0 ; Set tool 2 axis offsetsT0 ; Select tool 0 (laser) on startup

-

@ben_van said in New firmware 2.03RC2 available:

I spotted to minor issues that have nothing to do with your minimum-speed-issue though:

M350 E64 I1 ; Configure microstepping with interpolationDuet Wifi's TMC2660 only support interpolation with x16 microstepping. The above command won't do any harm but it will be "only" at x64 microstepping and won't be interpolated to x256.

M563 P1 S"Camera" G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C G10 P1 X-1 Y-0.6;There is a typo or copy-and-paste error in the middle line of this block. You define tool 1 but the middle line is still for tool 0.

-

@wilriker Ah thankyou for pointing this out. The G10 for tool 1 was a typo from copy/paste. I guess I never noticed since i don't have any heaters bound to the tool anyway. As for the M350 extruder microstepping, I will change to the following:

M350 X256 Y256 Z256 E256 I0

Not sure why I didn't have it written like that before..

-

@dc42 the m291 isn't unlocking a tool change still when called. Or is this impractical to do within a tool change?

-

@ben_van said in New firmware 2.03RC2 available:

As for the M350 extruder microstepping, I will change to the following:

M350 X256 Y256 Z256 E256 I0We don't recommend using native x256 microstepping. You will be limited to low speeds if you do, because generating the step pulses will use up too much processor time. It may be OK for a CNC machine, but not for a 3D printer.

-

@dc42 said in New firmware 2.03RC2 available:

@ben_van said in New firmware 2.03RC2 available:

As for the M350 extruder microstepping, I will change to the following:

M350 X256 Y256 Z256 E256 I0We don't recommend using native x256 microstepping. You will be limited to low speeds if you do, because generating the step pulses will use up too much processor time. It may be OK for a CNC machine, but not for a 3D printer.

I understand the computational expense of doing this.. going fast is the last thing i want

Most of the stuff made with this machine is seldom larger than 1mm, at speeds less than 50mm/min, and we have never experienced speed issues being limited by the CPU. This doesn't solve the G0 problem though..

Most of the stuff made with this machine is seldom larger than 1mm, at speeds less than 50mm/min, and we have never experienced speed issues being limited by the CPU. This doesn't solve the G0 problem though..

To give you an idea of why this matters, here is a sample pic of one of the things we can do with this machine + duet . It's too small to see properly with the naked eye.

-

@ben_van looks interesting, but what the heck is that?

-

@jv43 said in New firmware 2.03RC2 available:

@ben_van looks interesting, but what the heck is that?

It is a generic 2D scaffold used for cell culture. Tissue engineering is not my field of expertise but for the people I am working with it is. This is just a test print to show we are working on a scale smaller than that of a stem cell, and about the size of a T-cell.

Cells are present while this structure is printed and are encapsulated inside the bio-compatible gel, where they then grow/multiply inside it, as it is like food for them. I like to think of it like bread crumbs, where we can coax the cells to grow and develop in a very controlled manner.

Whilst i can't dive into many specifics of how everything works until something is published, I can say that we have been getting some very good results

The benefit of using all open source software is once the groundwork is in place for this method, we can easily use readily available 3D printer slicers to make any micro 3D structure straight from a CAD model, and hopefully be able to provide this to people wanting to experiment without the $100k+ pricetag that comes with anything with the word 'bio' in it.