Impossible for every timelapse script to comunicate with RRF?

-

Good morning, I've installed the latest version of RFF3 in my printer. I've already placed a Raspberri PI vith a PI cam to take timelapses. Well, I've tried three different Python script to make Timelapses and none of them worked...It looks like they all can't "comunicate" with the printer. This is the last one: https://github.com/DanalEstes/DuetLapse

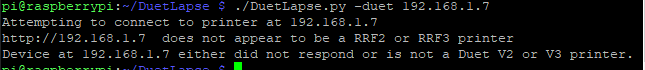

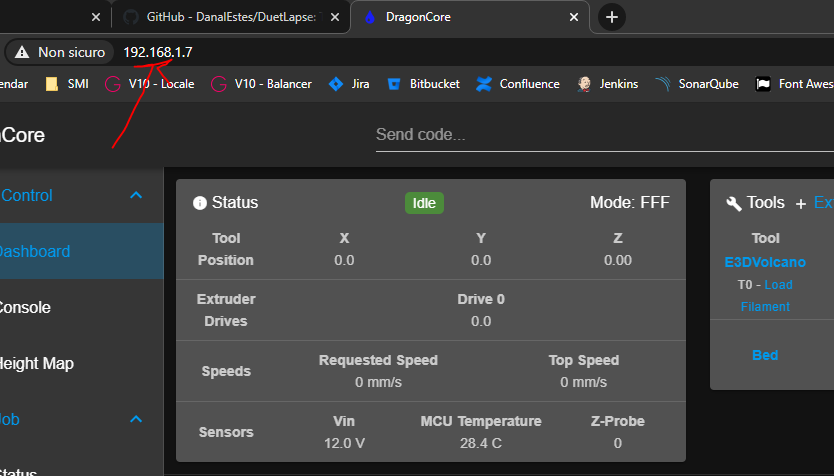

wich gives me this message:

but

At this point I'm starting to think that I forgot to set something in the firmware because three different scripts "suffers" of lack of comunication with the printer....what could I check?

this is my config.g (I've just obfuscated the password):

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Sun Nov 01 2020 08:34:36 GMT+0100 (Ora standard dell’Europa centrale); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"DragonCore" ; set printer name

M669 K1 ; select CoreXY mode; Network

M551 P"*********" ; set password

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S1 ; enable FTP

M586 P2 S1 ; enable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S0 ; physical drive 3 goes backwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 E16 I0 ; configure microstepping without interpolation

M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation

M92 X159.6 Y159.6 Z1188.11 E411.88 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X330 Y330 Z400 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X-39 Y0 Z1.10 ; set Z probe trigger value, offset and trigger height

M557 X40:290 Y10:320 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T50 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S0 H-1 ; set fan 2 value. Thermostatic control is turned off; Tools

M563 P0 S"E3DVolcano" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; load saved parameters from non-volatile memory; =========================================================

; = D R A G O N C O R E =

; =========================================================M671 X5:165:320:320:165:5 Y325:325:325:5:5:5 P0.5 ; point1 (40,320), point2 (165,320), point3 (290,320), point4 (290,10), point5 (165,10), point6 (10,10)

M591 D0 P3 C"e0_stop" S1 R70:130 L25.8 E3.0 ; Duet3D rotating magnet sensor for extruder drive 0 is connected to E0 endstop input, enabled, sensitivity 24.8mm.rev, 70% to 130% tolerance, 3mm detection length

M308 S10 Y"mcu-temp" A"MCU"

M911 S11.0 R11.5 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000"