Layer shift happening with RRF 3.2 on Duet2Ethernet?

-

Since going to 3.2 I am seeing consistent layer shifting on the X Axis. Nothing changed mechanically on the printer, and I thought it was some issue with a stepper, so I replaced it... and still seeing layer shifting (.1 - .5mm ). I haven't been able to pin point any other issues other than the upgrade to 3.2...

Happens on the X and U axis (U is run off the Duex, X is on the Duet), I havent noticed it happening on the Y axis.

Diag output

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.2 running on Duet Ethernet 1.02 or later + DueX5 Board ID: 08DGM-917NK-F23T0-6J1F6-3SD6T-1GBWD Used output buffers: 3 of 24 (24 max) === RTOS === Static ram: 23460 Dynamic ram: 72812 of which 60 recycled Never used RAM 15748, free system stack 108 words Tasks: NETWORK(ready,173) SENSORS(blocked,25) HEAT(blocked,309) DUEX(blocked,35) MAIN(running,448) IDLE(ready,19) Owned mutexes: === Platform === Last reset 01:31:39 ago, cause: software Last software reset at 2021-02-06 12:55, reason: User, GCodes spinning, available RAM 15748, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x04 Aux0 errors 0,0,0 MCU temperature: min 41.7, current 46.5, max 47.2 Supply voltage: min 23.9, current 24.0, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes Driver 0: position -39800, standstill, SG min/max 297/1023 Driver 1: position -2023, standstill, SG min/max 0/1023 Driver 2: position 6160, standstill, SG min/max 0/1023 Driver 3: position 11462, standstill, SG min/max not available Driver 4: position 0, ok, SG min/max 0/1023 Driver 5: position 0, ok, SG min/max 33/1023 Driver 6: position 0, ok, SG min/max 44/1023 Driver 7: position 0, ok, SG min/max 63/1023 Driver 8: position 0, standstill, SG min/max not available Driver 9: position 0, standstill, SG min/max not available Driver 10: position 0 Driver 11: position 0 Date/time: 2021-02-06 14:27:02 Cache data hit count 4294967295 Slowest loop: 219.32ms; fastest: 0.13ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 8 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 5.3ms, write time 11.0ms, max retries 0 === Move === DMs created 83, maxWait 239530ms, bed compensation in use: mesh, comp offset 0.000 === MainDDARing === Scheduled moves 21544, completed moves 21539, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state 3 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 Heater 0 is on, I-accum = 0.0 Heater 2 is on, I-accum = 0.6 === GCodes === Segments left: 1 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is doing "G1 X57.310 Y-19.981 E2.2739" in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 207.88ms; fastest: 0.02ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 Interface state active, link 100Mbps full duplex === Filament sensors === Extruder 1: pos 255.94, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 === DueX === Read count 1, 0.01 reads/minMy Config:

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Wed May 13 2020 20:53:22 GMT-0600 (Mountain Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Joes BFPv3.2" ; set printer name M929 P"eventlog.txt" S1 ; Set event log M575 P1 S1 B57600 ; Enable Panel Due Port. M555 P2 ; Set firmware compatibility to look like Marlin G21 ; Work in millimetres ; Network M552 S1 ; DHCP ;M552 P192.168.50.45 S1 ; enable network and set IP address ;M553 P255.255.255.0 ; set netmask ;M554 P192.168.50.1 ; set gateway M586 P0 S1 ; enable HTTP M586 P1 S1 ; enable FTP M586 P2 S0 ; disable Telnet ;##########Motor/Movement/Build Area############## ; Movement section M569 P0 S0; Drive 0 goes backwards(change to S0 to reverse it) -X M569 P1 S1 ; Drive 1 goes forwards ZL M569 P2 S1 ; Drive 2 goes forwards ZR M569 P3 S0 ; Drive 3 goes backwards E0 M569 P4 S1 ; Drive 4 goes forwards E1 M569 P5 S1 ; Drive 5 goes forwards U M569 P6 S1 ; Drive 6 goes backwards Y M569 P7 S0 ; Drive 7 goes forwards Y ;M569 P8 S1 ; Drive 8 goes forwards ;M569 P9 S1 ; Drive 9 goes forwards ; Motor Assignments M584 X0 Y6:7 Z1:2 U5 E3:4 ; U Axis for second X stepper, dual X and Dual Y and dualZ M350 Z16 I1; M350 X16 Y16 U16 I1; Configure microstepping with interpolation M92 X200.00 U200.00 Y200.00 Z1600 E809.00:395.2 ; set steps per mm (Updated for Hemera - 409 is stock) ; FEEDRATE CONVERSIONS ; 20mm/s = F1200 ; 70mm/s = F4200 ; 120mm/s = F7200 ;200mm/s = 12000 M201 X1400 Y1200 U1400 Z500 E7000:7000; Accelerations (mm/s^2) M203 X15000 Y15000 U15000 Z1800 E15000:15000 ; Maximum speeds (mm/min) M205 X13 Y13 U13 Z8 E50:50 ; Maximum jerk speeds mm/sec (Lowered to 13 for X and U in testing was 15 to check for skipped steps) M566 P1 ; Set Jerk Policy to 1 M204 P3000 T4000 ; Set printing and travel accelerations M906 X1100 Y1350 U1100 Z1150 E900:900 I15; Set motor currents (mA) and motor idle factor in percent (Raised X and U to 1100 for testing to overcome skippe steps) M84 S240 ; Set idle timeout ;############Call Pressure Advance / Dynamic Acceleration ######## M98 P"/macros/jobscripts/PressureAdvance.g" ; Home to the Min of X, Max of Y, Max of U set that to get the center zero. Use the non home axis as travel limits. M208 X152.5 Y180.4 U203.47 Z300 ; Set axis maxima (adjust to suit your machine) Add U+ to move alignment to the left. M208 X-200 Y-189.5 U-152.5 Z0 S1 ; Set axis minimum (adjust to make X=0 and Y=0 the CENTER of the bed) X Changed to 200 -3mm between the X and U wit the U being 3mm further back, so add -3 to the Y number ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y2 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 U2 S1 P"e0stop" ; configure active-high endstop for High end on U via pin e0Endstop ;M574 Z2 S1 P"zstop" ; configure active-high endstop for low end on Y via pin zstop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ;Motor Stall Detection M915 X Y U F0 R2 S15 M915 Z F0 R2 S30 ;Code to calibrate the lead screws M671 X-265:265 Y0:0 S1 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis Max correction of 1 ; #######Z-Probe####### M950 S0 C"duex.pwm1" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H3 F75 T2000 A10 R0.8 S0.004 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X16 Y28 Z0.9 ; Set Z probe trigger value (Higher the number the closer to the nozzle) After Hemera Install Z was +.28mm so dropped from Z1.235 to .955 M557 X-150:150 Y-150:150 S50 ; define mesh grid M376 H3 ; Taper off compensation over 3mm of height ; ##########Heaters/Sensors################### M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat"T0 Q10 ; create bed heater output on bedheat and map it to sensor 0 M143 H0 S135 ; set temperature limit for heater 0 to 135C M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 ;V6 Thermistor Cartridge E0 ;M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp ;V7 Beta Thermistor E0 M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 Q100 ; create nozzle heater output on e0heat and map it to sensor 1 ;M143 H1 S285 ; set temperature limit for heater 1 to 285C ; V7 300C Max temp M143 H1 S315 ; set temperature limit for heater 1 to 300C M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ;V6 Thermistor Cartridge E1 ;M308 S2 P"e1temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin e1temp ;V7 Beta Thermistor E1 M308 S2 P"e1temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin e1temp M950 H2 C"e1heat" T2 Q100 ; create nozzle heater output on e1heat and map it to sensor 2 ;M143 H2 S285 ; set temperature limit for heater 2 to 285C ;V7 300C Max temp M143 H2 S315 ; set temperature limit for heater 2 to 300C M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ;PT1000 calibration sensor ;M308 S8 P"duex.e5temp" Y"pt1000" A"Calibration"; sensor 8 (disabled for when not being used) ;Virtual Sensors M308 S3 P"mcu-temp" Y"mcu-temp" A"MCU" ; set virtual heater for MCU M308 S4 P"drivers" Y"drivers" A"Driver" ; set virtual heater for stepper drivers ;DHT Sensor M308 S5 P"duex.cs6" Y"dht22" A"Chamber Temp" M308 S6 P"S5.1" Y"dhthumidity" A"Chamber Humidity" ;############Call Filament Sensor Configurations######## M98 P"/macros/jobscripts/FilamentSensor.g" ; ##########Fans############# M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 C"E0 Part Fan" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 C"E1 Part Fan" S0 H-1 ; set fan 1 name and value. Thermostatic control is turned off M950 F2 C"fan2" Q1 ; create fan 2 on pin fan2 and set its frequency M106 P2 C"System Board Fans" S0 H3:4 T44:55 L50 X255 ; set fan 2 name and value. Thermostatic control is turned on M950 F3 C"duex.fan3" Q500 ; create fan 3 on pin duex.fan3 and set its frequency M106 P3 C"E0 HE Fan" S1 H1 T80 L0 X255 ; set fan 3 name and value. Thermostatic control is turned on M950 F4 C"duex.fan4" Q500 ; create fan 4 on pin duex.fan4 and set its frequency M106 P4 C"E1 HE Fan" S1 H2 T80 L0 X255 ; set fan 4 name and value. Thermostatic control is turned on M950 F5 C"duex.fan5" Q500 ; create fan 5 on pin duex.fan5 and set its frequency ;#####LEDS########### M106 P5 C"Pause LED" S0 H-1 ; set fan 5 name and value. Thermostatic control is turned off M950 F6 C"duex.fan6" Q500 ; create fan 6 on pin duex.fan6 and set its frequency M106 P6 C"E0 LED" S0 H-1 ; set fan 6 name and value. Thermostatic control is turned off M950 F7 C"duex.fan7" Q500 ; create fan 7 on pin duex.fan7 and set its frequency M106 P7 C"E1 LED" S0 H-1 ; set fan 7 name and value. Thermostatic control is turned off M950 F8 C"duex.fan8" Q500 ; create fan 8 on pin duex.fan8 and set its frequency ;M106 P8 C"Bed LED" S0 H-1 ; ###Commented out, no longer bed fan####set fan 8 name and value. Thermostatic control is turned off (### Going to bereplaced with chamber fan script) ;##### 24v Duex Heaters as Fan outputs ;M950 H3 C"duex.e3heat" Q500 T8 ;M141 H3 P0; Set chamber heater Not needed right now ;M106 P9 C"DummyHeater" S255 H-1 ;M950 F10 C"duex.e4heat" Q500 ;M106 P10 C"HeaterLED2" S255 H-1 ;M950 F11 C"duex.e5heat" Q500 ;M106 P11 C"HeaterLED3" S255 H-1 ;M950 F12 C"duex.e6heat" Q500 ;M106 P12 C"HeaterLED4" S255 H-1 ;############Call Chamber Fans########## ;M98 P"/macros/jobscripts/ChamberFan.g" ;########Cold Extrusion Limit########## M302 S185 R185 ;Filament settings M404 N1.75 D0.4 ;############Extend TEMPERATURE FAULT WARNINGS - ONLY FOR Nozzle/Tool changes ;M570 H1 P90 T80 ;Heater 1 (E0) Extended Fault Warnings ;M570 H2 P90 T80 ;Heater 2 (E1) extended fault warnings ;Disable heater warnings for ;###TOOL DEFINITIONS#### ; Tool 0 X - Left hand Extruder M563 P0 D0 H1 F0 X0 S"Left Titan Aero" ; tool 0 uses extruder 0 and heater 1 and maps X to X, use fan 2 as the print cooling fan G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets ;G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ;Tool 1 U - Right hand Extruder Hemera M563 P1 D1 H2 X3 F1 S"Right Hemera" ; tool 1 uses extruder 1 and heater 2 and maps X to U, use fan 1 as the print cooling fan G10 P1 X0 Y-6.48 Z0 ; Set initial tool 1 active and standby temperatures to 0C (Higher the negative number the futher back the U axis alings) ;G10 P1 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ;Tool 1 U - Right hand Extruder - Titan Aero Tool ;M563 P1 D1 H2 X3 F1 S"Right Titan Aero" ; tool 1 uses extruder 1 and heater 2 and maps X to U, use fan 1 as the print cooling fan ;G10 P1 X0 Y-6.65 Z0 ; Set initial tool 1 active and standby temperatures to 0C (Higher the negative number the futher back the U axis alings) ;G10 P1 R0 S0 ; Duplication Tool 2 M563 P2 D0:1 H1:2 X0:3 F0:1 S"Dual Duplication Print" ; tool 2 uses both extruders and hot end heaters, maps X to both X and U, and uses both print cooling fans G10 P2 X76 Y0 U-76 Z0 ; set tool offsets and temperatures for tool 2 ;G10 P2 R0 S0 M567 P2 E1:1 ; set mix ratio 100% on both extruders ; Mirror Tool 3 M563 P3 D0:1 H1:2 X0:3 F0:1 S"Dual Mirror Print" ; tool 2 uses both extruders and hot end heaters, maps X to both X and U, and uses both print cooling fans G10 P3 X85 Y0 U-85 Z0 ; set tool offsets and temperatures for tool 2 (+10mm offset for clearance due to the mirroring movements) ;G10 P3 R0 S0 M567 P3 E1:1 ; set mix ratio 100% on both extruders ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memoryRolling back to 3.1.1 isn't something I am keen on, but I am curious if I am missing something here?

-

try 3.2.1

edit nevermind. its only duet 3 related

-

I may have solved the issue on one side of the IDEX ( the pulley may have been loose... ) but I cant account for the otherside having similar issue.

-

@clegg78 said in Layer shift happening with RRF 3.2 on Duet2Ethernet?:

Rolling back to 3.1.1 isn't something I am keen on, but I am curious if I am missing something here?

Rolling back would be a good check to see if it's firmware related or not.

Upload the zip and reboot. https://github.com/Duet3D/RepRapFirmware/releases/download/3.1.1/Duet2and3Firmware-3.1.1.zip

Can you also send M98 P"config.g" and report the results?

-

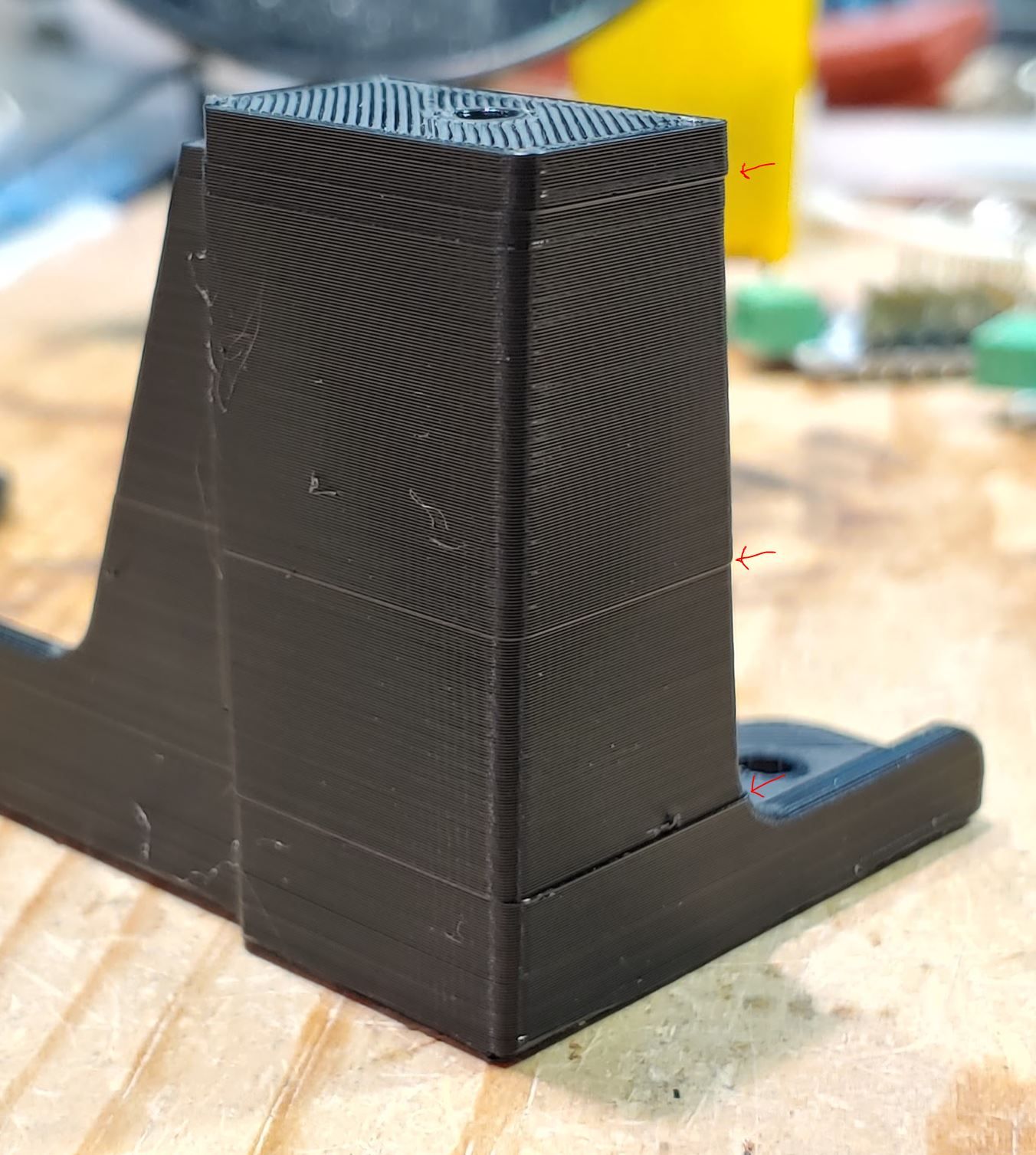

I seem to be having this same issue. After upgrading to 3.2.2 I started seeing layer shifts in prints. They seem to be only in the x axis, possibly a very tiny y shift at the same time. After printing this long print with 3 layer shifts, I downgraded to 3.1.1 and printed the same gcode again without changing anything else. The second print had no issues. Not totally conclusive I know, but suggestive.

I run a modified ATOM delta printer.

Each shift feels like the same distance, measures about 0.25mm. In this part it shifted negative, then positive, then positive.

M122 after downgrading, forgot to capture it while on 3.2.2.

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.1.1 running on Duet WiFi 1.02 or later Board ID: 08DDM-9FAM2-LW4S4-6JTDA-3SN6L-K3V7Y Used output buffers: 3 of 24 (22 max) === RTOS === Static ram: 27980 Dynamic ram: 94164 of which 60 recycled Exception stack ram used: 264 Never used ram: 8604 Tasks: NETWORK(ready,384) HEAT(blocked,1224) MAIN(running,1824) IDLE(ready,80) Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:00:44 ago, cause: power up Last software reset details not available Error status: 0 MCU temperature: min 11.0, current 16.4, max 16.5 Supply voltage: min 23.8, current 24.0, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes Driver 0: standstill, SG min/max not available Driver 1: standstill, SG min/max not available Driver 2: standstill, SG min/max not available Driver 3: standstill, SG min/max not available Driver 4: standstill, SG min/max not available Date/time: 2021-02-20 11:15:45 Cache data hit count 69622987 Slowest loop: 6.92ms; fastest: 0.15ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 2.7ms, write time 0.0ms, max retries 0 === Move === Hiccups: 0(0), FreeDm: 169, MinFreeDm: 169, MaxWait: 0ms Bed compensation in use: mesh, comp offset 0.000 === MainDDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === AuxDDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === Heat === Bed heaters = 0 -1 -1 -1, chamberHeaters = 2 -1 -1 -1 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 30.56ms; fastest: 0.00ms Responder states: HTTP(2) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 - WiFi - Network state is active WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 0 WiFi firmware version 1.23 WiFi MAC address 60:01:94:34:3e:3d WiFi Vcc 3.36, reset reason Hardware watchdog WiFi flash size 4194304, free heap 25480 WiFi IP address 192.168.12.123 WiFi signal strength -64dBm, reconnections 0, sleep mode modem Socket states: 4 0 0 0 0 0 0 0 === Filament sensors === Extruder 0 sensor: ok; General preferences M111 S0 ; Debugging off G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M555 P1 ; Set firmware compatibility to look like RepRapFirmare ;M555 P2 ; Set firmware compatibility to look like Marlin G29 S1 ; Load Mesh Bed Compensation Map from SD Card M911 S19.5 R22 P"G91 M83 G1 Z3 E-5 F1000" ; Setup auto pause on power fail ;*** The homed height is deliberately set too high in the following - you will adjust it during calibration. M665 R105.11 L225.51 B110 H365 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; Put your endstop adjustments here, or let auto calibration find them M208 Z0 S1 ; Set minimum Z ; Endstops M574 X2 S1 P"xstop" M574 Y2 S1 P"ystop" M574 Z2 S1 P"zstop" ; Z-Probe M558 P5 C"^!e0stop" F60 T2000 A3 S0.01 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds, active high G31 P600 X0 Y0 Z4.805 ; Set Z probe trigger value, offset and trigger height (Position for Inductive Iouch center mount) ;G31 P600 X0 Y0 Z14.805 ; Set Z probe trigger value, offset and trigger height (Position for IR Touch center mount) ;G31 P600 X0 Y0 Z-12.03 ; Set Z probe trigger value, offset and trigger height (Position for micro switch center mount) ;G31 P600 X0 Y0 Z15.765 ; Set Z probe trigger value, offset and trigger height (Position for induction center mount) ;G31 P600 X-24 Y-1 Z4.4 ; Set Z probe trigger value, offset and trigger height (Position for my Chimera print head) ; Calibration M557 R105 S20 ; Define mesh grid. Radius and Spacing ; Filament Sensor (Using Endstop Input) M591 P2 C"exp.e2stop" S1 D0 ; External Triggers M950 P1 C"e1stop" M581 P1 T1 S0 ; Use a falling edge on E0 endstop to trigger a print Pause command ; Drives M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes forwards M92 X160 Y160 Z160 E412 ; Set steps per mm at default 16x microstepping M350 X16 Y16 Z16 E128 I1 ; Configure microstepping with interpolation M566 X1200 Y1200 Z1200 E600 ; Set maximum instantaneous speed changes (mm/min) M203 X30000 Y30000 Z30000 E30000 ; Set maximum speeds (mm/min) M201 X2000 Y2000 Z2000 E2000 ; Set accelerations (mm/s^2) M906 X1500 Y1500 Z1500 E800 I35 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Stall Detection M915 P0 S15 F0 H400 R3 ;On stall detection rehome and restart M915 P1 S15 F0 H400 R3 ;On stall detection rehome and restart M915 P2 S15 F0 H400 R3 ;On stall detection rehome and restart ; Temperature Sensors M308 S0 P"bed_temp" Y"thermistor" T100000 B4725 C7.060000e-8 A"Bed" M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.060000e-8 A"Hot End" M308 S2 P"e1temp" Y"thermistor" T100000 B4725 C7.060000e-8 A"Air" ; Heater to Temperature Sensor Connection ; Set Bed Heater M950 H0 c"bed_heat" T0 M140 H0 ; Set Hot End Heater M950 H1 c"e0heat" T1 ; Set Chamber Heater M950 H2 c"exp.heater4" Q0 T2 M141 H2 ; Heater Config M301 H0 S1.00 P10 I0.1 D200 T0.4 W180 B30 ; Use PID on bed heater (may require further tuning) M143 H0 S120 ; Set temperature limit for heater 0 to 120C M143 H1 S310 ; Set temperature limit for heater 1 to 310C ;M143 H2 S120 ; Set temperature limit for heater 2 to 120C M570 S120 ; Configure heater fault detection. Cancel if heating takes longer than time (seconds) ; Tools Z Offset ; More negative z value is farther from the build plate ; Tools M563 P0 D0 H1 S"Chimera CORE 0.4mm KKIINNGG" ; Define tool 0 G10 P0 X0 Y0 Z-10.8 ; Set tool 0 axis offsets (FlexPlate Magnet with PEI Powder Coated Spring Steel) ;G10 P0 X0 Y0 Z-9.8 ; Set tool 0 axis offsets (Old PEI Bed) G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C M563 P1 D0 H1 S"Volcano 1mm" ; Define tool 1 G10 P1 X0 Y0 Z-18.6 ; Set tool 1 axis offsets (FlexPlate Magnet with PEI Powder Coated Steel) ;G10 P1 X0 Y0 Z-16.8 ; Set tool 1 axis offsets (Old PEI Bed) G10 P1 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C ; Network M550 PATOM2 ; Set machine name M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Fans M950 F0 C"fan0" M950 F1 C"fan1" M950 F2 C"!fan2" Q500 M950 F3 C"e1heat" M106 P0 S0 H-1 C"Part Cooling" M106 P1 S1 H1 T50 C"Hotend Fan" M106 P2 C"Enclosure Fan" M106 P3 S0 L1 H-1 C"Circulation Fan" ; Water Cooling (hot end and motors) Power Enable M950 F4 C"exp.heater3" M106 P4 S1 H1 T50 C"WaterCooling" ; Enclosure Filter Fan Power Enable M950 F5 C"exp.heater5" M106 P5 S1 H1 T35 C"EnclosureFan" ; Default tool selection ;T0 M912 P0 S-18 ; CPU Temp Calibration M501 ; Load overrides -

Hmm, well after some more prints still on 3.1.1 I got the layer shifting again. So I guess the problem is something else...