Magnetic Filament Sensor - false alarms

-

I recently purchased Magnetic Filament Sensor. 1st I had issue with RRF 3.3beta1, I did have issues with delayed alarm or alarm was not triggered at all. After downgrade to RRF 3.2.2 I have opposite, I have false too little movement alarms, this time I suspect that it is mechanical problem and not related to RRF, but I might be wrong.

Sensor is mounted right before direct drive Hemera extruder via PTFE tube. I'm running Duet 3 + Toolboard. Sensor is connected to Toolboard.

What I tried:

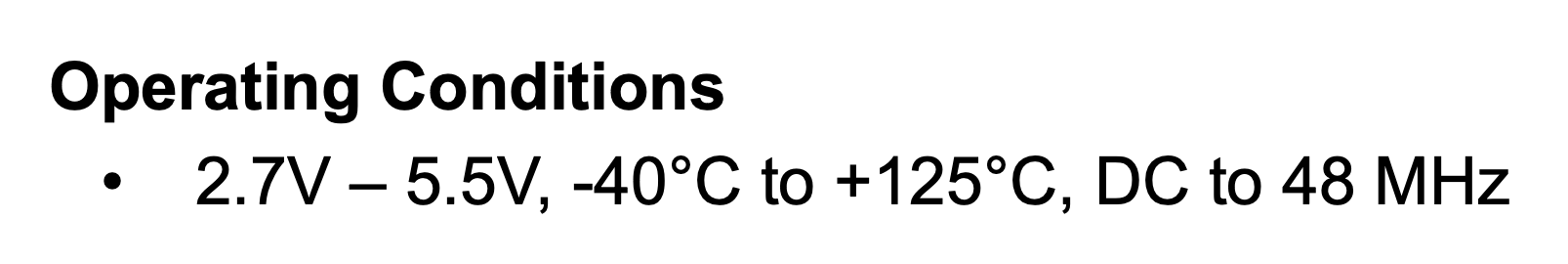

- Sanded down sensor case so that I have recommended values for 'agc' of 85 to 105. Now I have 94, so right in the middle of recommended values;

- I changed PTFE tube which has smaller ID, to have tight fit and minimise the slack and keep filament as straight as possible;

- Rechecked wiring, sensor assembly, no issues there.

I suspect that there is an issue with slipping filament, but maybe I am wrong, and if there is I don't have anymore ideas how to get rid slipping filament issue.

I bought sensor from https://hobby-store.pl, maybe this is just coincident but person from this post has the same issues and bought sensor from the same store: https://forum.duet3d.com/topic/17132/magnetic-filament-sensor

Do you have any recommendations?

Now I can even see that max value went up, what that could mean?

config.g

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name M669 K1 ; select CoreXY mode ; Drives M569 P0.0 S0 ; physical drive 0.0 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S0 ; physical drive 0.2 goes backwards M569 P0.3 S0 ; physical drive 0.3 goes backwards M569 P0.4 S0 ; physical drive 0.4 goes backwards M569 P121.0 S0 ; physical drive 121.0 goes forwards M584 X0.0 Y0.1 Z0.2:0.3:0.4 E121.0 ; set drive mapping M671 X-34.2:180.5:395.2 Y56:368.7:56 S8 ; Motor order: Front Left (1 - P0.2), Rear Center (2 - P0.3), Front Right (3 - P0.4) M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X100.00 Y100.00 Z800.00 E409.00 ; set steps per mm M566 X900.00 Y900.00 Z90 E240.00 ; set maximum instantaneous speed changes (mm/min) M203 X12000.00 12000.00 Z240.00 E2400.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z250.00 E1000.00 ; set accelerations (mm/s^2) M906 X1200 Y1200 Z1200 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X350 Y350 Z350 S0 ; set axis maxima ; Endstops M574 X1 S1 P"121.io2.in" ; configure active-high endstop for low end on X via pin 121.io1.in M574 Y2 S1 P"io1.in" ; configure active-high endstop for low end on Y via pin io1.in ; Z-Probe M950 S0 C"121.io0.out" ; create servo pin 0 for BLTouch M558 P9 C"^121.io0.in" H3 F120 T8000 A5 R0.2 S0.03 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X-34 Y9 Z1.99 M557 X36:316 Y9:349 S20 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"121.temp0" Y"pt1000" ; configure sensor 1 as thermistor on pin 121.temp0 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S285 ; set temperature limit for heater 1 to 300C ; Fans M950 F0 C"!121.out1+out1.tach" Q500 ; create fan 0 on pin 121.out1 and set its frequency M106 P0 S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"121.out2+out2.tach" Q25000 ; create fan 1 on pin 121.out2 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"!out4+out4.tach" Q25000 ; create fan 2 on pin out4 and set its frequency M106 P2 C"PSU1" S0.4 H-1 ; set fan 2 name and value. Thermostatic control is turned off M950 F3 C"!out5+out5.tach" Q25000 ; create fan 3 on pin out5 and set its frequency M106 P3 C"PSU2" S0.4 H-1 ; set fan 3 name and value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Rotating Magnet Filament Monitor M591 D0 P3 C"121.io1.in" S0 R85:115 L24.15 E3.0 ; Duet3D rotating magnet sensor for extruder drive 0 is connected to E0 endstop input, enabled, sensitivity 24.8mm.rev, 70% to 130% tolerance, 3mm detection length ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDueM122:

M122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.2.2 running on Duet 3 MB6HC v1.01 or later (SBC mode) Board ID: 08DJM-956BA-NA3TJ-6J9DA-3SN6S-9AAUV Used output buffers: 1 of 40 (18 max) === RTOS === Static ram: 149788 Dynamic ram: 63524 of which 200 recycled Never used RAM 145320, free system stack 126 words Tasks: Linux(ready,95) HEAT(blocked,297) CanReceiv(blocked,813) CanSender(blocked,344) CanClock(blocked,352) TMC(blocked,17) MAIN(running,720) IDLE(ready,19) Owned mutexes: HTTP(MAIN) === Platform === Last reset 01:03:37 ago, cause: software Last software reset at 2021-03-01 06:04, reason: User, none spinning, available RAM 145352, slot 0 Software reset code 0x0012 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0044a000 BFAR 0x00000000 SP 0x00000000 Task Linu Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 Aux1 errors 0,0,0 MCU temperature: min 36.9, current 38.0, max 38.2 Supply voltage: min 23.9, current 24.1, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.1, current 12.1, max 12.2, under voltage events: 0 Driver 0: position 44921, ok, reads 16581, writes 21 timeouts 0, SG min/max 0/1023 Driver 1: position -2011, ok, reads 16581, writes 21 timeouts 0, SG min/max 0/1023 Driver 2: position 3204, standstill, reads 16581, writes 21 timeouts 0, SG min/max 0/1023 Driver 3: position 0, standstill, reads 16581, writes 21 timeouts 0, SG min/max 0/1023 Driver 4: position 0, standstill, reads 16581, writes 21 timeouts 0, SG min/max 0/1023 Driver 5: position 0, standstill, reads 16591, writes 11 timeouts 0, SG min/max 0/0 Date/time: 2021-03-01 07:08:22 Slowest loop: 154.52ms; fastest: 0.04ms === Storage === Free file entries: 10 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === DMs created 125, maxWait 34680ms, bed compensation in use: mesh, comp offset 0.000 === MainDDARing === Scheduled moves 32894, completed moves 32888, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 1], CDDA state 3 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 Heater 0 is on, I-accum = 0.2 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 1 Movement lock held by null HTTP* is doing "M122" in state(s) 0 Telnet is idle in state(s) 0 File* is doing "G1 F2763.586914" in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue* is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Filament sensors === Extruder 0: no data received === CAN === Messages queued 47399, send timeouts 0, received 47856, lost 0, longest wait 3ms for reply type 6048, free buffers 48 === SBC interface === State: 4, failed transfers: 0 Last transfer: 2ms ago RX/TX seq numbers: 23875/23875 SPI underruns 0, overruns 0 Number of disconnects: 0, IAP RAM available 0x2c8a8 Buffer RX/TX: 208/1720-0 === Duet Control Server === Duet Control Server v3.2.2 File: Buffered code: G1 F2763.587 Buffered code: G1 X162.992 Y237.189 E0.05731 Buffered code: G1 X163.212 Y236.105 E0.14235 Buffered code: G1 X163.275 Y235.159 E0.12190 Buffered code: G1 X163.644 Y234.872 E0.06004 Buffered code: G1 X164.517 Y233.989 E0.15980 Buffered code: G1 X165.391 Y233.221 E0.14958 Buffered code: G1 X166.265 Y232.779 E0.12595 Buffered code: G1 X167.138 Y232.609 E0.11446 Buffered code: G1 X168.012 Y232.636 E0.11241 Buffered code: G1 X168.885 Y232.838 E0.11534 Buffered code: G1 X169.759 Y233.251 E0.12426 Buffered code: G1 X170.632 Y233.931 E0.14239 Buffered code: G1 X171.506 Y234.814 E0.15980 Buffered code: G1 X172.379 Y235.582 E0.14958 Buffered code: G1 X173.253 Y236.024 E0.12595 Buffered code: G1 X174.126 Y236.194 E0.11446 Buffered code: G1 X175.000 Y236.167 E0.11241 Buffered code: G1 X175.874 Y235.965 E0.11534 Buffered code: G1 X176.747 Y235.552 E0.12426 Buffered code: G1 X177.621 Y234.872 E0.14239 Buffered code: G1 X178.494 Y233.989 E0.15980 Buffered code: G1 X179.368 Y233.221 E0.14958 Buffered code: G1 X180.241 Y232.779 E0.12595 Buffered code: G1 X181.115 Y232.609 E0.11446 Buffered code: G1 X181.988 Y232.636 E0.11241 Buffered code: G1 X182.862 Y232.838 E0.11534 Buffered code: G1 X183.736 Y233.251 E0.12426 Buffered code: G1 X184.609 Y233.931 E0.14239 Buffered code: G1 X185.483 Y234.814 E0.15980 Buffered code: G1 X186.356 Y235.582 E0.14958 Buffered code: G1 X186.764 Y235.788 E0.05879 ==> 1512 bytes Code buffer space: 2376 Configured SPI speed: 8000000 Hz Full transfers per second: 40.61 Maximum length of RX/TX data transfers: 2856/1664 File /opt/dsf/sd/gcodes/f119e32e-cf3a-46c6-97b3-237b4b389e3c_0.8n_0.4mm_PLA__3h34m.gcode is selected, processingM122 B121:

M122 B121 Diagnostics for board 121: Duet TOOL1LC firmware version 3.2.2 (2021-02-11) Bootloader ID: SAMC21 bootloader version 2.2 (2021-01-16b1) Never used RAM 3540, free system stack 22 words HEAT 90 CanAsync 89 CanRecv 83 TMC 56 MAIN 218 AIN 64 Last reset 01:49:43 ago, cause: power up Last software reset time unknown, reason: OutOfMemory, available RAM 15440, slot 1 Software reset code 0x01c0 ICSR 0x00000000 SP 0x20003638 Task MAIN Freestk 796 ok Stack: 20000d10 0001234f 20000d10 0001e5f1 00000000 00004008 20000d10 0001e565 20000d0c 00004000 a5a5a5a5 a5a5a5a5 00000000 0001e42d 00004000 000191b1 a5a5a5a5 000191cd a5a5a5a5 0001219d a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 Driver 0: position 7722896, 409.0 steps/mm, ok, SG min/max 0/28, read errors 0, write errors 0, ifcnt 17, reads 14832, writes 17, timeouts 0, DMA errors 0 Moves scheduled 42412, completed 42409, in progress 1, hiccups 0 Next step interrupt due in 272 ticks, enabled VIN: 24.1V MCU temperature: min 22.8C, current 54.5C, max 56.2C Ticks since heat task active 88, ADC conversions started 6557110, completed 6557108, timed out 0 Last sensors broadcast 0x00000002 found 1 91 ticks ago, loop time 0 CAN messages queued 82301, send timeouts 0, received 101775, lost 0, free buffers 36 === Filament sensors === Interrupt 5 to 34us, poll 8 to 742us Driver 0: pos 208.12, errs: frame 10 parity 0 ovrun 0 pol 0 ovdue 0 -

@gunrak said in Magnetic Filament Sensor - false alarms:

Sensor is mounted right before direct drive Hemera extruder via PTFE tube.

Is the sensor in horizontal position then? As far as I understand, the steelball should be above the filament path and drop down by gravity. Then the sensor has to be in vertical position.

-

Yes it is mounted in horisontal position. I am not sure what do you mean by steelball. Inside the sensor there is idler bearing which is pushed by spring. I don't think that gravity would help much in this case.

-

@gunrak

OK, I confused it with the Finda-probe. Sorry. -

No problem.

There is one more thing that slipped through my mind. Even if cable is short between sensor and toolboard, Steeper motor and steeper motor cables are quite close, maybe I should try to use shielded cable?

Later today I will be in my workshop and crimp shielded cable, maybe there is some interference from stepper and that could help. -

The measured sensitivity started off looking sensible, but increased to -240 to +395% over a few tens of minutes. Here are some possible reasons:

- Filament slippage, as you suspect.

- Severe interference pickup by the cable. Run M122 at the end of the print and look at the filament monitor error counts. That will indicate whether interference is a problem.

- We saw a small number of instances during inspection of the magnet not being held securely on the shaft, leaving it free to rotate on the shaft. So check that the magnet is secure.

- It could possibly be that a part of your print uses the extruder in a way that confuses the firmware. If that's the case then it should be consistent if you repeat the print.

-

@dc42 Thanks for quick replay.

- I will make shielded cable and try to route it away from stepper cable. I will check the errors after my print finishes.

- I will check the magnet.

-

@dc42

Maybe it's not the right place to discuss it here, but a optical mouse sensor reading the surface of a rough idler roller would have a much higher resolution than a magnet&hall combo. And the rough surface of the roller avoids slipping, too.Just my 2 Cent

-

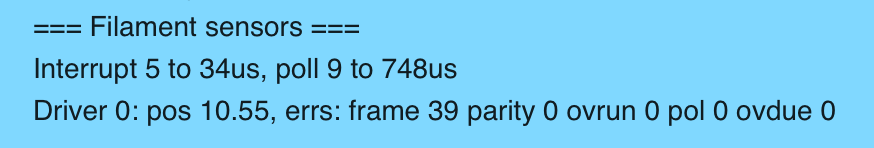

print finished. Could you point out where exactly should I look for filament monitor error counts?

Here is M122:M122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.2.2 running on Duet 3 MB6HC v1.01 or later (SBC mode) Board ID: 08DJM-956BA-NA3TJ-6J9DA-3SN6S-9AAUV Used output buffers: 5 of 40 (25 max) === RTOS === Static ram: 149788 Dynamic ram: 63524 of which 200 recycled Never used RAM 145320, free system stack 122 words Tasks: Linux(ready,93) HEAT(blocked,297) CanReceiv(blocked,809) CanSender(blocked,337) CanClock(blocked,352) TMC(blocked,17) MAIN(running,720) IDLE(ready,19) Owned mutexes: HTTP(MAIN) === Platform === Last reset 04:17:50 ago, cause: software Last software reset at 2021-03-01 06:04, reason: User, none spinning, available RAM 145352, slot 0 Software reset code 0x0012 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0044a000 BFAR 0x00000000 SP 0x00000000 Task Linu Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 Aux1 errors 0,0,0 MCU temperature: min 38.4, current 38.5, max 38.7 Supply voltage: min 23.9, current 24.0, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.1, current 12.1, max 12.2, under voltage events: 0 Driver 0: position 35000, standstill, reads 23835, writes 1 timeouts 0, SG min/max 0/193 Driver 1: position -35000, standstill, reads 23835, writes 1 timeouts 0, SG min/max 0/588 Driver 2: position 14397, standstill, reads 23835, writes 1 timeouts 0, SG min/max 0/966 Driver 3: position 0, standstill, reads 23835, writes 1 timeouts 0, SG min/max 0/1023 Driver 4: position 0, standstill, reads 23835, writes 1 timeouts 0, SG min/max 0/149 Driver 5: position 0, standstill, reads 23835, writes 0 timeouts 0, SG min/max not available Date/time: 2021-03-01 10:22:36 Slowest loop: 89.64ms; fastest: 0.05ms === Storage === Free file entries: 10 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === DMs created 125, maxWait 158ms, bed compensation in use: mesh, comp offset 0.000 === MainDDARing === Scheduled moves 187797, completed moves 187797, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 Heater 0 is on, I-accum = 0.2 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP* is doing "M122" in state(s) 0 Telnet is idle in state(s) 0 File* is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue* is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause* is idle in state(s) 0 Code queue is empty. === Filament sensors === Extruder 0: no data received === CAN === Messages queued 296, send timeouts 0, received 502, lost 0, longest wait 1ms for reply type 6029, free buffers 48 === SBC interface === State: 4, failed transfers: 0 Last transfer: 1ms ago RX/TX seq numbers: 8784/8784 SPI underruns 0, overruns 0 Number of disconnects: 0, IAP RAM available 0x2c8a8 Buffer RX/TX: 0/0-0 === Duet Control Server === Duet Control Server v3.2.2 Code buffer space: 4096 Configured SPI speed: 8000000 Hz Full transfers per second: 37.24 Maximum length of RX/TX data transfers: 5152/1664M122 B121 Diagnostics for board 121: Duet TOOL1LC firmware version 3.2.2 (2021-02-11) Bootloader ID: SAMC21 bootloader version 2.2 (2021-01-16b1) Never used RAM 3540, free system stack 22 words HEAT 86 CanAsync 89 CanRecv 83 TMC 56 MAIN 218 AIN 64 Last reset 05:06:54 ago, cause: power up Last software reset time unknown, reason: OutOfMemory, available RAM 15440, slot 1 Software reset code 0x01c0 ICSR 0x00000000 SP 0x20003638 Task MAIN Freestk 796 ok Stack: 20000d10 0001234f 20000d10 0001e5f1 00000000 00004008 20000d10 0001e565 20000d0c 00004000 a5a5a5a5 a5a5a5a5 00000000 0001e42d 00004000 000191b1 a5a5a5a5 000191cd a5a5a5a5 0001219d a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 Driver 0: position 23666167, 409.0 steps/mm, standstill, SG min/max 0/32, read errors 0, write errors 0, ifcnt 18, reads 17544, writes 1, timeouts 0, DMA errors 0 Moves scheduled 192404, completed 192404, in progress 0, hiccups 0 No step interrupt scheduled VIN: 24.2V MCU temperature: min 22.8C, current 41.5C, max 56.2C Ticks since heat task active 159, ADC conversions started 18341517, completed 18341516, timed out 0 Last sensors broadcast 0x00000002 found 1 162 ticks ago, loop time 0 CAN messages queued 148007, send timeouts 0, received 256537, lost 0, free buffers 36 === Filament sensors === Interrupt 5 to 34us, poll 9 to 744us Driver 0: pos 311.13, errs: frame 72 parity 0 ovrun 0 pol 0 ovdue 0 -

Will give it a try:

-

Apparently no difference with shelded cable routed as far as possible from stepper and stepper cable:

Next I will check the magnet.

-

@dc42 said in Magnetic Filament Sensor - false alarms:

- Filament slippage, as you suspect.

Could filament slippage actually increase max up to 115% as you can see in screenshot? And negative min, how could I achieve that due to slippage? correct me if I am wrong but negative value means that filament is traveling backward, correct? If so, slippage should not cause the issue.

- Severe interference pickup by the cable. Run M122 at the end of the print and look at the filament monitor error counts. That will indicate whether interference is a problem.

Changed wired to shielded cable, wired away from all possible interferers, did not help. In theory it still could be potential issue.

- We saw a small number of instances during inspection of the magnet not being held securely on the shaft, leaving it free to rotate on the shaft. So check that the magnet is secure.

Still have to check this, but again, could freely rotating magnet cause negative min, and 115% max?

- It could possibly be that a part of your print uses the extruder in a way that confuses the firmware. If that's the case then it should be consistent if you repeat the print.

Print is plain as it possible be, I do use 0.8mm nozzle, but print speeds are relatively low and retraction is set to 0.6mm 35 mm/s. Not sure that such a plain print could could cause confusion to firmware.

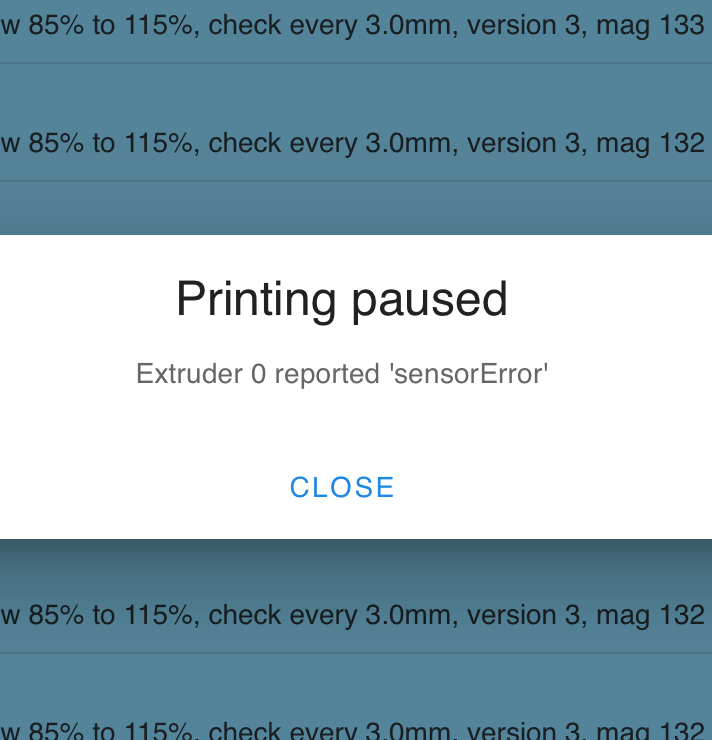

Before last print finished 99%, it was paused due to sensor error or something like that, even if filament monitoring set to disabled (S0)

Could it actually be firmware bug? Anything to do with the fact that I use toolboard? Is there any way to debug/log/view communication between sensor and firmware?

-

@gunrak said in Magnetic Filament Sensor - false alarms:

Anything to do with the fact that I use toolboard?

@gunrak said in Magnetic Filament Sensor - false alarms:

MCU temperature: min 22.8C, current 41.5C, max 56.2C

Maybe not related, but IMHO the MCU temp is pretty high on the toolboard.

-

And it happened again!

-

-

Last print:

01/03/2021, 16:52:29 M122 B121 Diagnostics for board 121: Duet TOOL1LC firmware version 3.2.2 (2021-02-11) Bootloader ID: SAMC21 bootloader version 2.2 (2021-01-16b1) Never used RAM 3540, free system stack 22 words HEAT 86 CanAsync 89 CanRecv 83 TMC 56 MAIN 218 AIN 64 Last reset 04:19:02 ago, cause: power up Last software reset time unknown, reason: OutOfMemory, available RAM 15440, slot 1 Software reset code 0x01c0 ICSR 0x00000000 SP 0x20003638 Task MAIN Freestk 796 ok Stack: 20000d10 0001234f 20000d10 0001e5f1 00000000 00004008 20000d10 0001e565 20000d0c 00004000 a5a5a5a5 a5a5a5a5 00000000 0001e42d 00004000 000191b1 a5a5a5a5 000191cd a5a5a5a5 0001219d a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 Driver 0: position 21862546, 409.0 steps/mm, standstill, SG min/max 0/28, read errors 0, write errors 0, ifcnt 14, reads 37736, writes 14, timeouts 0, DMA errors 0 Moves scheduled 183899, completed 183899, in progress 0, hiccups 0 No step interrupt scheduled VIN: 24.2V MCU temperature: min 32.6C, current 46.7C, max 57.0C Ticks since heat task active 31, ADC conversions started 15480195, completed 15480195, timed out 0 Last sensors broadcast 0x00000002 found 1 35 ticks ago, loop time 0 CAN messages queued 194317, send timeouts 0, received 323864, lost 0, free buffers 36 === Filament sensors === Interrupt 5 to 34us, poll 9 to 748us Driver 0: pos 10.55, errs: frame 39 parity 0 ovrun 0 pol 0 ovdue 0 01/03/2021, 16:51:47 M122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.2.2 running on Duet 3 MB6HC v1.01 or later (SBC mode) Board ID: 08DJM-956BA-NA3TJ-6J9DA-3SN6S-9AAUV Used output buffers: 7 of 40 (39 max) === RTOS === Static ram: 149788 Dynamic ram: 63388 of which 172 recycled Never used RAM 145484, free system stack 130 words Tasks: Linux(ready,95) HEAT(blocked,272) CanReceiv(blocked,809) CanSender(blocked,339) CanClock(blocked,352) TMC(blocked,17) MAIN(running,675) IDLE(ready,19) Owned mutexes: HTTP(MAIN) === Platform === Last reset 04:18:19 ago, cause: power up Last software reset at 2021-03-01 06:04, reason: User, none spinning, available RAM 145352, slot 0 Software reset code 0x0012 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0044a000 BFAR 0x00000000 SP 0x00000000 Task Linu Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 Aux1 errors 0,0,0 MCU temperature: min 38.1, current 39.4, max 40.2 Supply voltage: min 23.9, current 24.0, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.1, current 12.1, max 12.2, under voltage events: 0 Driver 0: position 35000, standstill, reads 9594, writes 1 timeouts 0, SG min/max 0/1023 Driver 1: position -35000, standstill, reads 9594, writes 1 timeouts 0, SG min/max 0/1023 Driver 2: position 14397, standstill, reads 9594, writes 1 timeouts 0, SG min/max 0/1023 Driver 3: position 0, standstill, reads 9594, writes 1 timeouts 0, SG min/max 0/1023 Driver 4: position 0, standstill, reads 9595, writes 1 timeouts 0, SG min/max 0/1023 Driver 5: position 0, standstill, reads 9596, writes 0 timeouts 0, SG min/max not available Date/time: 2021-03-01 14:51:46 Slowest loop: 198.42ms; fastest: 0.02ms === Storage === Free file entries: 10 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === DMs created 125, maxWait 160ms, bed compensation in use: mesh, comp offset 0.000 === MainDDARing === Scheduled moves 187795, completed moves 187795, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 Heater 0 is on, I-accum = 0.2 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP* is doing "M122" in state(s) 0 Telnet is idle in state(s) 0 File* is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue* is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause* is idle in state(s) 0 Code queue is empty. === Filament sensors === Extruder 0: no data received === CAN === Messages queued 229693, send timeouts 0, received 162403, lost 0, longest wait 3ms for reply type 6048, free buffers 48 === SBC interface === State: 4, failed transfers: 0 Last transfer: 1ms ago RX/TX seq numbers: 8291/8291 SPI underruns 0, overruns 0 Number of disconnects: 0, IAP RAM available 0x2c8a8 Buffer RX/TX: 0/0-0 === Duet Control Server === Duet Control Server v3.2.2 Code buffer space: 4096 Configured SPI speed: 8000000 Hz Full transfers per second: 44.04 Maximum length of RX/TX data transfers: 5076/1684 -

I did check the magnet and it sits firmly on the shaft.

So, I am out of ideas, what else I could do.

Duet 3 is probably the best 3D printer board available on the market, combined with Toolboard it offers unique functionality. I love it. It is so good that I have temptation to replace my CNCs Duet 2 with Duet 3, especially if I keep SBC mode in mind.

Magnetic Filament Sensor is exactly 65EUR of disappointment + wasted time and filament on failed prints, especially if it not clear where is the issue. Hardware, software, user error?

It defiantly has great potential, but it should be reliable, I guess I will try to return it and get the refund, and print out simple microswitch filament run out sensor.

-

@o_lampe said in Magnetic Filament Sensor - false alarms:

@dc42

Maybe it's not the right place to discuss it here, but a optical mouse sensor reading the surface of a rough idler roller would have a much higher resolution than a magnet&hall combo. And the rough surface of the roller avoids slipping, too.Just my 2 Cent

Have you seen https://forum.duet3d.com/topic/18497/indirect-laser-monitor-remix-ii-working ?

-

@gunrak said in Magnetic Filament Sensor - false alarms:

So, I am out of ideas, what else I could do.

Please post the GCode file you are printing. I have a machine using a tool board with magnetic filament monitor, so I will try printing your part on it.

-

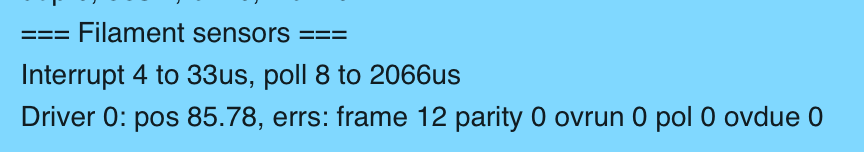

I did upgrade to RRF 3.3beta1, just to see if this will make any difference.

Errors are still there, but a bit less than yesterday printing the same file:

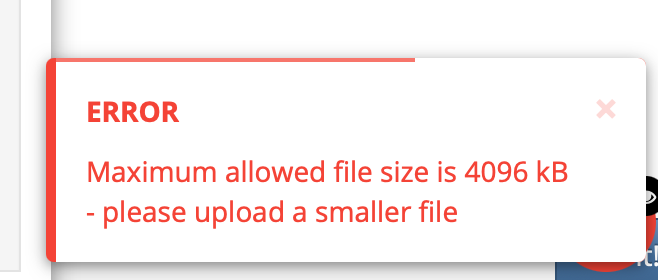

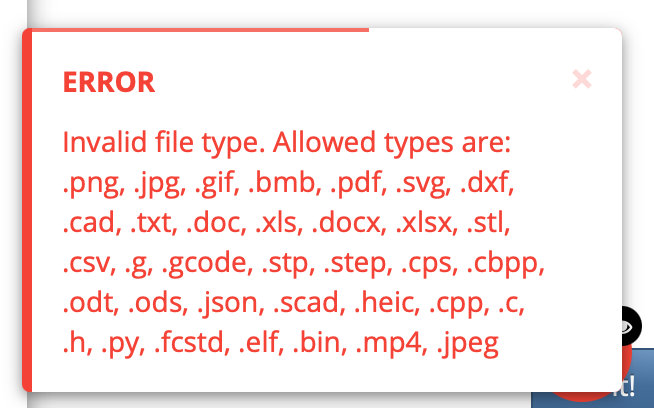

and .zip is not allowed to upload.

Uploaded to DropBox: https://www.dropbox.com/s/tnevy8i5yhnym6x/f119e32e-cf3a-46c6-97b3-237b4b389e3c_0.8n_0.4mm_PLA__3h34m.gcode?dl=0