Hi guys,

I'm playing with my new extruder and would like to know how much it extrudes in a real print.

Is it possible to display extrusion volume in DWC? Printspeed, layerheight and layerwidth? should be available for calculations.

I extruded in free air to get ballpark numbers, but real life is different.

Best posts made by o_lampe

-

Displaying current extrusion volume possible?posted in Duet Web Control wishlist

-

RE: Music skipping beats after firmware update (3.4.0beta6)posted in Tuning and tweaking

@gtaman

It's actually the same:- create a global variable blockDaemon

- set global.blockDaemon = true at the start of the M300 file

- set global.blockDaemon = false at the end

Then anyone using Daemon.g for real can add these lines

while global.blockDaemon = true G4 S1000 -

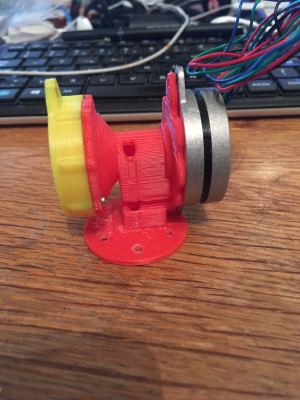

RE: Hollow shaft extruderposted in General Discussion

Had my first simpleFOC project running today. It was an old brushless gimbal controller without encoders and with 8bit mcu.

I was able to control two motors independently and relatively smooth (USB power only)

The atmega328 was also at it's limit, but I'm now confident it will work well with the right mcu. -

RE: External stepper drivers (TB6600) on duet 2 wifiposted in Using Duet Controllers

@m0ck1nj

Check the TB6600 datasheet. If it is OK with 3.3V signals on step, dir, enable you can wire it directly.

If it needs differential signals or 5V you can use the much cheaper expansion breakout board -

RE: Hollow shaft extruderposted in General Discussion

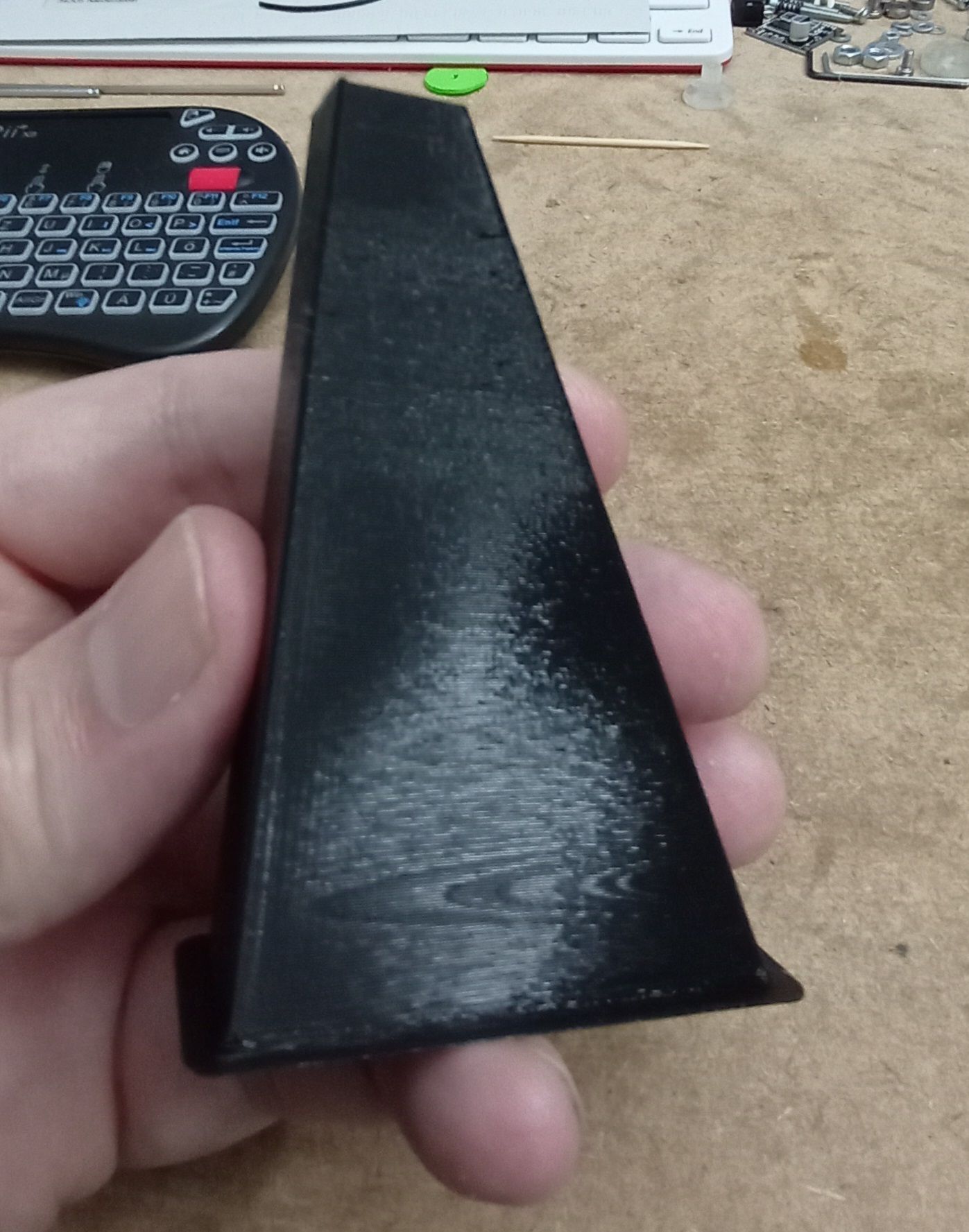

First print today

Instead of a benchy, I tried the extruder-woodgrain test. Yes there is some, but hardly visible. The corners were sharp and even, that was a relieve. The close loop PID setting are quite soft, so I expected worse...

At the top third, the printspeed got so low, that the filament overheated. 10°C less temp and it was nice and shiny again.

-

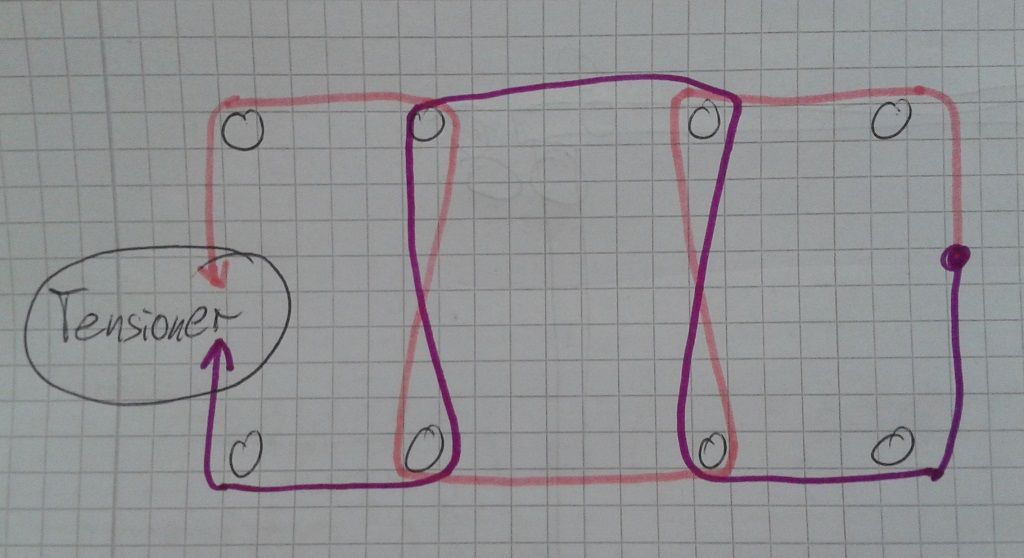

#- (hash) printer with super simple gantryposted in Example setups and prints

Hi gents,

I started pondering the idea to build a hash-printer with the least amount of hardware. The video of the original design shows the typical shaft & dual belt approach we've seen on H-bots and cross-gantry printers to avoid racking.

But I want to use a dual roller constraint as I did on other occasions before. I wasn't sure if that would also work with two beams per axis, so I cobbled together a quick and dirty test rig.

To make it clearer how to wrap the Aramid fishing line around the four rollers I started with a drawing:

This is the Y-axis only, imagine two more extrusions horizontally to build a '#'.

And finally I made demo video to show how easy it is to move the beam from only one side without racking.

-

RE: Accelerometer Usageposted in Beta Firmware

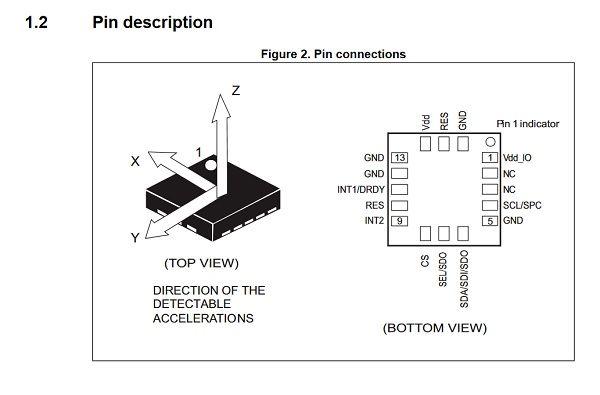

According to this picture

- positive X goes to the right

- positive Y goes to the back

- positive Z goes up

-

RE: Smart Effector including toolboard-capabilities?posted in Smart effector for delta printers

@dc42 said in Smart Effector including toolboard-capabilities?:

It's clear to me that the Orbiter could not be used with a Smart Effector made to the current dimensions. We would need to increase the rod spacing to at least 80mm in order to accommodate the various parts of the extruder. We are looking into this, however it would make it unsuitable for the smaller delta printers.

Hi dc42,

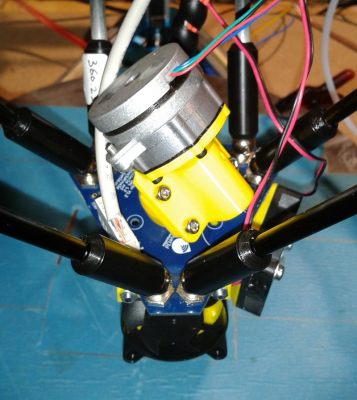

I just stumbled across this thread and wanted to guide you back to 2016 , when we discussed the cycloidal direct drive. (I still have it laying around)

I've made an 45 degree adapter for it, that suited the smart effector pretty well.

Another way to mount it, was the split motor/gearbox idea.

I could try to reuse my motor and design a BMG-drive for the Smart effector?

-

Display current back EMF for tuningposted in Duet Web Control wishlist

Hi devs,

based on the "extrusion volume" thread, I also think a back EMF calculator as DWC plugin would be helpful for tuning.

The required parameters are almost completely known for the calculation. It only misses coil resistance and inductivity (AFAIK)Since my Duet boards run on their own network, I don't have access to the EMF calculator at reprapfirmware.org

If we could integrate it as plugin and use 'live' values from the current object model/gcode file, we'd have a nice tuning tool

-

RE: Add 'pre-retract' and 'post-retract'posted in Firmware wishlist

@nikscha I like the idea. It's like the tool-change macros.

But there is also a problem when you retract / unretract within a toolchange.

Maybe you can solve your problem by renaming G10/G11 to G10.1 and G11.1 via postprocessing. Then you need only one macro for retraction (which also contains the real G10 move)

Latest posts made by o_lampe

-

RE: Dual Extruder on Polar Printerposted in General Discussion

@LüDi

Did you try Cura taking charge of the tool offset?

Using offsets in RRF is a bit counterintuitive regarding the +/- sign of the offset.

Check out theG10 L2orG10 L20description. It might give you another option to make it work. -

RE: Closed loop firmware for CNCposted in CNC

AFAIK, the current closed loop strategy in RRF is to add the missed steps to the axis involved. But that could end up very bad on CNC machines.

Slowing down the other axis' would be the safer way, but with a buffered path planner it's still not in real time. -

RE: Dead driver or dying board?posted in Duet Hardware and wiring

@kazolar I ruined my CNC frame with a similar problem. One Y motor stopped and skipped steps, the other went on.

To avoid that once and for all, you should add an "anti racking" mechanism.

Maybe couple both motors (dual shaft motors preferably) with a shaft extension or do what is common in big machines: add a cord/wire to the crossbeam to eliminate racking.

Check out the first few pages of my hashPrinter thread, where I used that method a lot. There are also some links to my Youtube channel, where I demonstrate the anti racking effect.PS: If you want more people to read your wall of text, you should edit it for better readability.

-

RE: Integrating AI with 3D printerposted in 3D Printing General Chat

This smells like ChatGPT BS.

OTOH, a bit more autotuning in some areas (pressure advance and input shaping) coming from a local PC or SBC would be nice.... -

RE: Spirograph emulator with Duet2posted in CNC

@mrehorstdmd Currently I'm using Sandify, but I can also produce gcode from .dxf files. With inkscape I could theoreticaly use any bitmap to generate patterns and I could manually drag every knot of a path out of the zones.

I used it frequently, when my K40 laser was new.I haven't thought to look elsewhere, but if others (CNC or laser scene? ) have the same problem with keep out zones, I'd be happy to know.

Is the PERL post processor open source? I'm looking for a good starting point to write my own.(open file, modify gcode lines, write new file) -

RE: Spirograph emulator with Duet2posted in CNC

@droftarts said in Spirograph emulator with Duet2:

I'd say it was rare to design a machine with the axes inside the build area.

You're right, but I wanted the footprint of the table aka delta tower-triangle to be small.

I got a nice 38cm dia glasstable with a predrilled footprint of 320mm. I'll have to place the towers accordingly.

@droftarts said in Spirograph emulator with Duet2:

Currently only one keep out zone is supported

Guess, I have to write a postprocessor which takes care of three keepout zones and doesn't quit the job.

-

RE: Spirograph emulator with Duet2posted in CNC

Just found out that M599 can define keep out zones. But searching for "keep out" in the Wiki gave no result...

Bad news is, it only works on Duet3 boards due to RAM restrictions.Guess I can build a few sandify patterns, that match such an odd working area, but wipe-patterns usually apply to rectangular or polar areas only

-

RE: Spirograph emulator with Duet2posted in CNC

The Slim Delta is alive and I could reach areas outside of the triangle.

The problem is, how do I tell RRF that it mustn't foul the towers?

I know there are people using that for their leadscrew area and such, but I couldn't find it in the Wiki.

-

RE: 3-phase 2-pole CPAP pump with 6HC?posted in Duet Hardware and wiring

@gnydick These controllers require hall sensors. I couldn't find info about them in your motor sheet.

If it comes with hall sensors, you're probably good. (400W seems an awful lot for these small controllers)

If not you can try rc-hobby ESCs. They work without halls, but need a "hobby-servo" compatible signal. RRF can send that, too. It's just a matter of declaration. -

RE: Sovol SV08 Multiple Motion System Upgrade.posted in My Duet controlled machine

@dwuk3d said in Sovol SV08 Multiple Motion System Upgrade.:

Plus a more serious issue.

I might have to do with endstop offset adjustment.