STUMPED : Slicer sending Garbage Start.g GCode to 1LC toolboard

-

@sputnikoc3d said in STUMPED : Slicer sending Garbage Start.g GCode to 1LC toolboard:

https://github.com/prusa3d/PrusaSlicer/issues/6726

theres 25 other posted issue across superslicer git issue forum and prusa slicer ive read nearly 1000 posts in threads on the issue.

Both slicers will add G10 / M116 or G10 P0 [ prusa slicer ] / M116 [ sslicer ]

Here the dev of superslicer indicates you can turn the autogenerated gcode behavior off - but I cant seem to sort out how

Here is the start code from my install of Prusa 2.3.3.

This is with extruder/bed temps set to some typical values:

M107 M190 S60 ; set bed temperature and wait for it to be reached G10 S200 ; set temperature M98 P"print_begin.g" G10 S200 ; set temperature M116 ; wait for temperature to be reached G21 ; set units to millimeters G90 ; use absolute coordinates M82 ; use absolute distances for extrusion G92 E0```This is with extruder/bed temps set to zero:

M107 M98 P"print_begin.g" G21 ; set units to millimeters G90 ; use absolute coordinates M82 ; use absolute distances for extrusion G92 E0As you can clearly see you only get the G10/M116 commands when extruder/bed temps are set.

Perhaps this behavior is only true for version 2.3.3 - but that is the version I have.

Frederick

-

with temps set in slicer 2.3.3

M73 P0 R65 M107 G10 S215 ; set temperature ;TYPE:Custom ;========================================== ;Start GCode DasVoron2.4 - as of 8-30-2021 ;Print Area is X10 Y10 to X285 Y285 ;========================================== G21 ; set units to millimeters G90 ; use absolute positioning M83 ; relative extrusion mode M140 S65 ; set bed H0 temp T0 ; set Tool 0 to proper tool to get this started M568 P0 R175 S215 A1 ; Sets Tool0 /Nozz/ 1st layer Temp / Standby Temps | Sets Tool0 to Standby M561 ; Disable ANY and ALL Mesh Bed Level Compensation G28 ; home X / Y / Z w/out mesh bed level G29 S1 P"/sys/heightmap.csv" ; Load and use latest heightmap for Mesh Bed Compensation | heightmap.csv is Default/latest G92 E0.0 ; reset extruder distance position G1 X5 Y5 Z20 F5000 ; go to Steve's Dribble Zone and wait M190 S65 ; wait for bed temp M116 H0 S12 ; RRF3 - Waits for H0/Bed to get within 12*C | S5 Param | of Set Temp Above M568 P0 S215 A2 ; Sets Tool0 /Nozz/ | S - to 1st layer Temp | A-Sets Tool0 to Active /0-1-2/ M116 P0 H1 ; Waits for Tool0 / H1 Heater 1 Nozz to get to get to Print temps in M568 above G1 Z0.24 F3000 ; drop to 0.24 print height G1 X5 Y5 F3000 ; move to purge strip start position G1 E10.0 F140 ; puddle from Tilley Test G1 Y60.0 E9.0 F1000.0 ; intro line 1 from Tilley Test G1 Y100.0 E12.5 F1000.0 ; intro line 2 from Tilley Test G92 E0.0 ; reset extruder distance position G10 S215 ; set temperature M116 ; wait for temperature to be reached G21 ; set units to millimeters G90 ; use absolute coordinates M83 ; use relative distances for extrusion M572 D0 S0.06 G1 F2400.000 G1 X139.381 Y130.088 E0.04073 G1 X140.090 Y129.928 E0.02459 G1 X140.820 Y129.869 E0.02478 G1 X159.131 Y129.869 E0.61939 G1 X160.056 Y129.953 E0.03144 G1 X160.957 Y130.202 E0.03163 G1 X161.800 Y130.608 E0.03163 G1 X162.551 Y131.154 E0.03144without temps set / using custom start.g code from before

M73 P0 R65 M107 ;TYPE:Custom ;========================================== ;Start GCode DasVoron2.4 - as of 8-30-2021 ;Print Area is X10 Y10 to X285 Y285 ;========================================== G21 ; set units to millimeters G90 ; use absolute positioning M83 ; relative extrusion mode M140 S0 ; set bed H0 temp T0 ; set Tool 0 to proper tool to get this started M568 P0 R175 S0 A1 ; Sets Tool0 /Nozz/ 1st layer Temp / Standby Temps | Sets Tool0 to Standby M561 ; Disable ANY and ALL Mesh Bed Level Compensation G28 ; home X / Y / Z w/out mesh bed level G29 S1 P"/sys/heightmap.csv" ; Load and use latest heightmap for Mesh Bed Compensation | heightmap.csv is Default/latest G92 E0.0 ; reset extruder distance position G1 X5 Y5 Z20 F5000 ; go to Steve's Dribble Zone and wait M190 S0 ; wait for bed temp M116 H0 S12 ; RRF3 - Waits for H0/Bed to get within 12*C | S5 Param | of Set Temp Above M568 P0 S0 A2 ; Sets Tool0 /Nozz/ | S - to 1st layer Temp | A-Sets Tool0 to Active /0-1-2/ M116 P0 H1 ; Waits for Tool0 / H1 Heater 1 Nozz to get to get to Print temps in M568 above G1 Z0.24 F3000 ; drop to 0.24 print height G1 X5 Y5 F3000 ; move to purge strip start position G1 E10.0 F140 ; puddle from Tilley Test G1 Y60.0 E9.0 F1000.0 ; intro line 1 from Tilley Test G1 Y100.0 E12.5 F1000.0 ; intro line 2 from Tilley Test G92 E0.0 ; reset extruder distance position G21 ; set units to millimeters G90 ; use absolute coordinates M83 ; use relative distances for extrusion M572 D0 S0.06 ;LAYER_CHANGE ;Z:0.24 ;HEIGHT:0.24 M73 P0 R64 G1 Z0.240 F12000.000 G10 ; retract G1 X138.275 Y130.564 G11 ; unretract ;TYPE:Skirt ;WIDTH:0.42 G1 F2400.000 G1 X139.381 Y130.088 E0.04073 G1 X140.090 Y129.928 E0.02459 G1 X140.820 Y129.869 E0.02478 G1 X159.131 Y129.869 E0.61939 G1 X160.056 Y129.953 E0.03144 G1 X160.957 Y130.202 E0.03163 G1 X161.800 Y130.608 E0.03163 G1 X162.551 Y131.154 E0.03144with zero temps set in filaments / using a print start macro in slicer's custom start.g section

*** of note - it now generate E0.xxxx filament extrusion values. First time I tried it did not - odd

; generated by PrusaSlicer 2.3.3+win64 on 2021-09-04 at 18:18:14 UTC ; ; external perimeters extrusion width = 0.45mm ; perimeters extrusion width = 0.45mm ; infill extrusion width = 0.45mm ; solid infill extrusion width = 0.45mm ; top infill extrusion width = 0.40mm ; first layer extrusion width = 0.42mm M73 P0 R64 M107 ;TYPE:Custom M98 P"Print_Start.g" G21 ; set units to millimeters G90 ; use absolute coordinates M83 ; use relative distances for extrusion M703 ; Use / Engage Firmware retraction | Make sure this filament is in Duet w / filament / config..g ;M572 D0 S0.05 ; This should be in filaments / config..g ;LAYER_CHANGE ;Z:0.24 ;HEIGHT:0.24 G10 ; retract G1 Z0.240 F12000.000 G1 X138.275 Y130.564 G11 ; unretract ;TYPE:Skirt ;WIDTH:0.42 G1 F2400.000 G1 X139.381 Y130.088 E0.04162 G1 X140.090 Y129.928 E0.02512 G1 X140.820 Y129.869 E0.02532 G1 X159.131 Y129.869 E0.63285 G1 X160.056 Y129.953 E0.03212 G1 X160.957 Y130.202 E0.03231So three slices - different approaches .... still odd behaviors

-

-

RepRap ... for these examples. reprap / sprinter exhibits same issues tho.

got the error again too

Warning Discarded std reply src=121 RID=4094 exp 206""

Separate issue:

Error: in file macro line 1 M221 Parameter 'D' too high

filament config.g error

M221 S0.94 D121.0 ; set extrusion multiplierSeems I do not address the E0 toolboard extruder via the 121 prefix. ; super noob

-

@sputnikoc3d said in STUMPED : Slicer sending Garbage Start.g GCode to 1LC toolboard:

RepRap ... for these examples. reprap / sprinter exhibits same issues tho.

Odd.

got the error again too

Warning Discarded std reply src=121 RID=4094 exp 206""

Error: in file macro line 1 M221 Parameter 'D' too high

Well that should be an easy error to find and fix.

How about exporting from Prusa the config bundle with printers and post it here. I will import it into my Prusa install and see if I can find what you are doing that I am not doing which is causing the differences we are seeing.

Frederick

-

well as much as I appreciate that ... I think Id be wasting your time brother.

Im heading towards your macro methodology. I think long term it will serve me better. Prusa Slicer keeps driving more and more prusa centric interface and stuff into their fork, and Superslicer dev[s] seem agnostic to reprap and lean towards klipper. Being slicer agnostic and having more control over my well being seems prudent. Leaving the slicer to just handle basic slicing and pathing etc and besides Ive been looking closely recently at iDeaMaker. Super Slicer seems pretty nice and familiar as well. The devil I DO know sort of thing.

It seems a small price to pay to merely have to stuff a pair of M codes into the start.g if I still use that - but I think the /macro/Print_Start.g approach is where its at. Id rather spend time ironing out the details of getting that working and porting my filament profiles into that ... Seems like its working that way ... by passing my old way in start.g and using a macro to set all my environment and safeguards myself.

-

@fcwilt my last code example above that uses the M98 P"Print_Start.g" - seems to have worked and generated some proper gcode.

I just need to get a good Print_Start.g macro written

that said - Im trying to get my head round my filaments config.g. So far here's what I think I need to have in each one.

M221 - extrusion multiplier

M207 - retraction / de retraction / speeds and distances

M568 - nozzle print and standby temps

M140 - bed temps

M572 - Pressure Advanceuncertain items

Input shaping settings ? have no idea how that works yetGlobal Var's - not sure what needs to be set and where else they will be used.

-

@sputnikoc3d said in STUMPED : Slicer sending Garbage Start.g GCode to 1LC toolboard:

@fcwilt my last code example above that uses the M98 P"Print_Start.g" - seems to have worked and generated some proper gcode.

I just need to get a good Print_Start.g macro written

that said - Im trying to get my head round my filaments config.g. So far here's what I think I need to have in each one.

M221 - extrusion multiplier

M207 - retraction / de retraction / speeds and distances

M568 - nozzle print and standby temps

M140 - bed temps

M572 - Pressure Advanceuncertain items

Input shaping settings ? have no idea how that works yetGlobal Var's - not sure what needs to be set and where else they will be used.

Well I think I posted most of my print_begin.g file - didn't I?

And the global variables are something that can be used or not. Nothing special about them. In my case it just allowed me to change certain priming/retract settings as needed by different filaments, in the filament config.g file and later use them in the print_begin.g file.

Frederick

-

@fcwilt - yes I have your macro saved and Im going thru it ... stealing what I understand and incorporating that and finessing my stuff in there - fingers crossed

thanks for all the help.

-

@fcwilt just went all in on 3.4.0 beta 3 - lol fingeres crossed ..

-

@sputnikoc3d said in STUMPED : Slicer sending Garbage Start.g GCode to 1LC toolboard:

@fcwilt just went all in on 3.4.0 beta 3 - lol fingeres crossed ..

You are braver then I - I wait until the release version is out .

Frederick

-

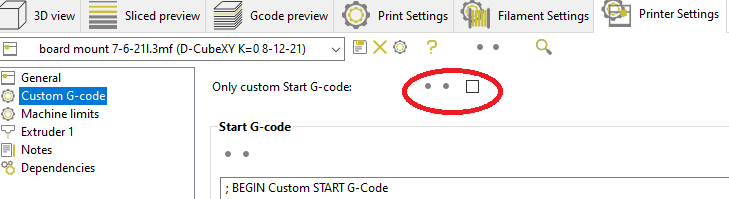

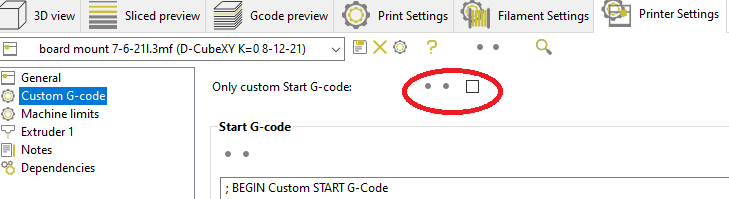

@fcwilt - heres a solution for Super Slicer ...

https://github.com/supermerill/SuperSlicer/issues/425#issuecomment-913036749

found the setting [ if it were a snake it have bit me ]

-

@sputnikoc3d said in STUMPED : Slicer sending Garbage Start.g GCode to 1LC toolboard:

@fcwilt - heres a solution for Super Slicer ...

https://github.com/supermerill/SuperSlicer/issues/425#issuecomment-913036749

found the setting [ if it were a snake it have bit me ]

I like that. Every slicer ought to have that option rather than having to figure which other settings will stop the generation of this or that bit of code.

Good work.

Frederick