@gloomyandy posted

[[ Both the 5160 and 2209 were a pain to tune with the 0.9 steppers. I started out with 2209s and managed to get them working pretty well. ]]

But this is in Stealthchop mode ONLY 100% of the time ... utilizing print speeds < 100 mm/s and non print travel moves < 200 mm/s right ? Probably fine for MOST cartesians but not the OPS - travel moves over 200 mm/s are doable as are much faster print moves.

Operating in stealthchop for several of us is just not a solution - especially on a Voron 2.4 - purpose built to far exceed Stealthchop limitations.

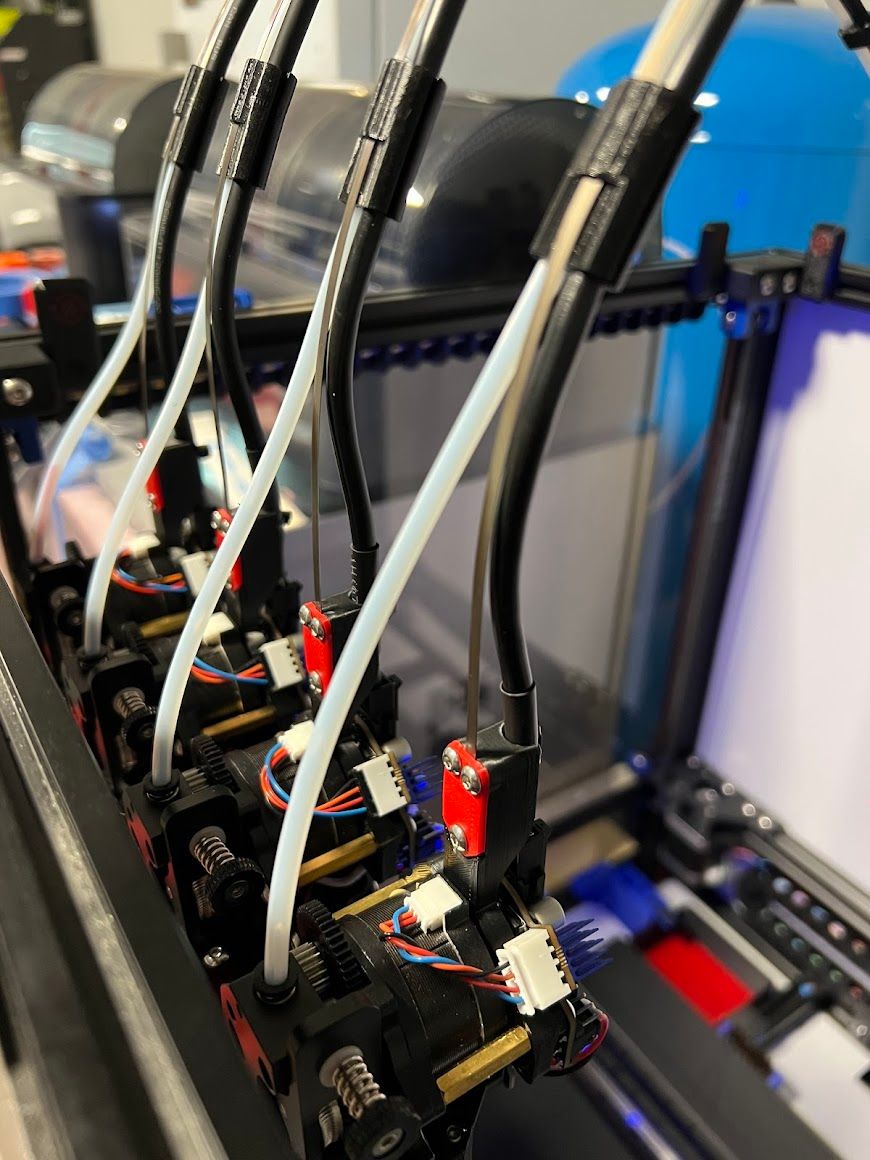

The issue we're fighting isnt Homing sensitivity and the PITA that that is- we've gotten past that - we're now missing steps during print moves < 100 mm/s in Spreadcycle. Thats a very serious issue for a 3d print and the FW - somewhere. This post is far beyond mere inconvenience, its now to the point of the Duet 3 Mini 5+ viability as a useable board.

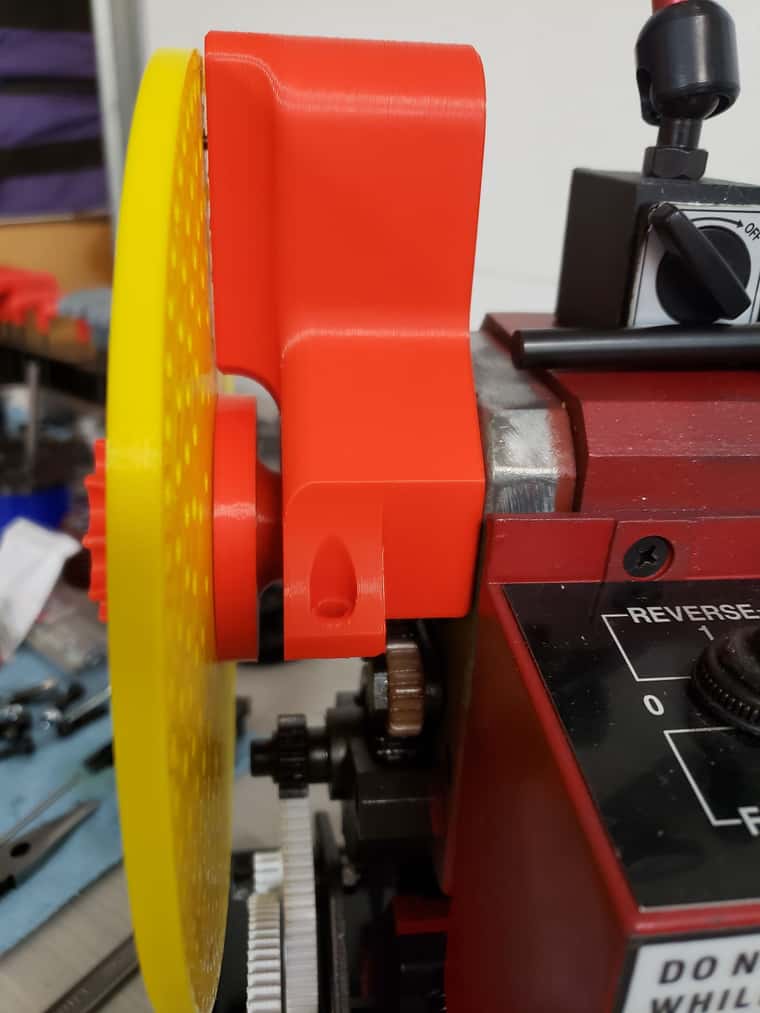

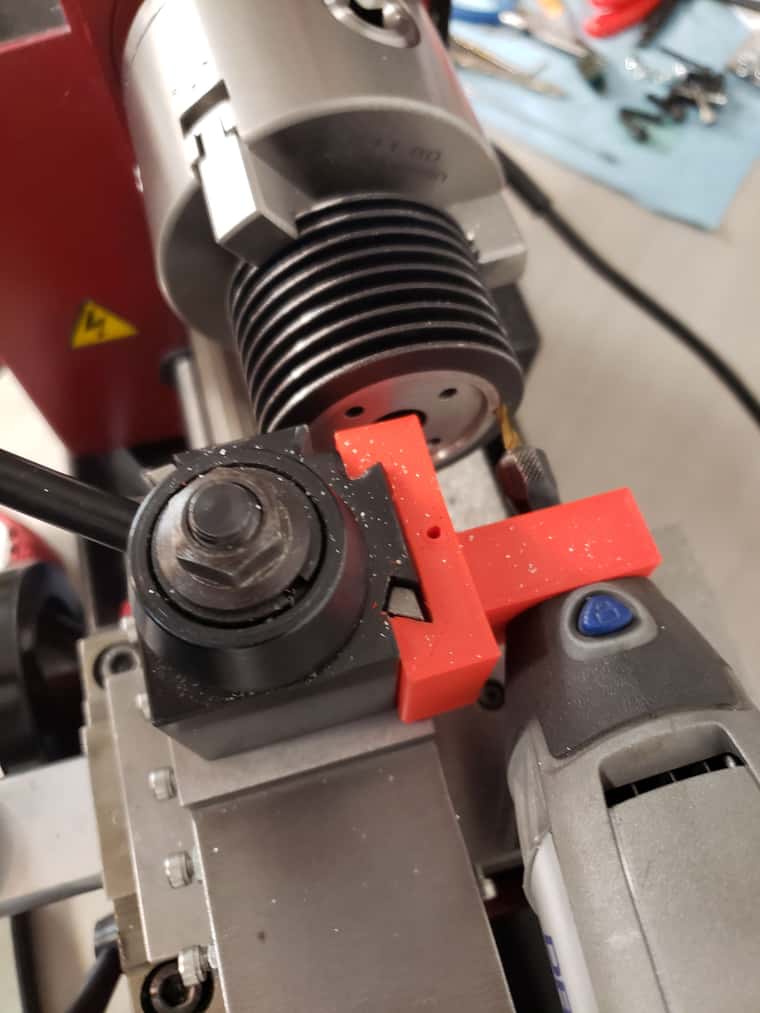

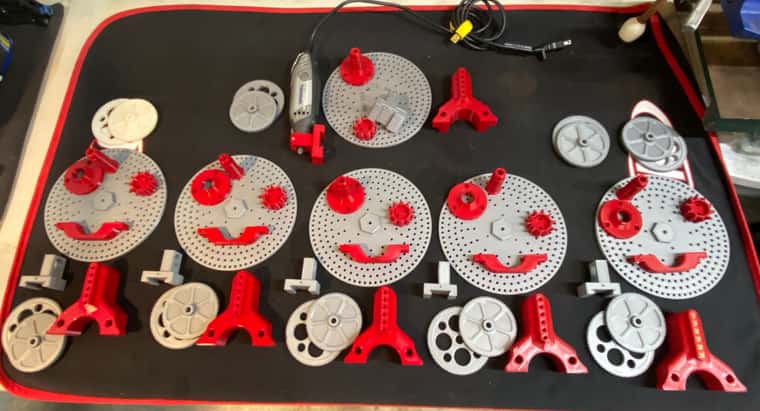

Rookie red stuff is ...

Rookie red stuff is ...