Finally. magnetic sensor working

-

Re: Duet magnetic filament monitor adventures

1.

Unfortunately, not DUET. Orthus.

Excellent case. Good fittings. Very good ideea with sensitivity switch.

It is also difficult to use though. I am using it on lowest sensitivity setting (3 settings, with a microswitch, rotary). On any other, it will sense any vibration. Maybe on the medium setting would work, but only very close to extruder, wich I cant, as I have not space there (water cooling, direct drive).Long story short, here are my settings:

M591 D0 P7 C"1.io1.in" S1 R20:200 E10 L1.246 A0 ; filament magnetic monitor Orthus.Rather... very permisive settings. It is enough to sense common problems, like ... nozzle scratching to bed.

For those needing a very thin first layer, I suggest using a macro for enabling/disabling the magnetic sensor, while, in fact, this would not be needed at all in most normal situation, with a proper setup.2.

If anybody needs a second or even a third filament sensor (for the same tool I mean), they may use triggers:M950 J7 C"1.io3.in" ;define pin GPIO 7 1.io3.in M581 T2 P7 S0 R0 ; define trigger T2, pause on filament over, comutarea pe active /inactive edge pin GPIO 7, anytimeFor me, T2 trigger is

; trigger2.g ; called when filament is over M118 P2 S"S-a terminat rola de filament" M118 P3 S"S-a terminat rola de filament" M25 ;pauseI did not tested the messaging, but the M25. Very simple and effective, I am starting to like this ... gcode thing.

Why this sensor? It is needed because I want to splice the filament long before leaving the magnetic sensor, as usually it is a pain to change filament, when working with a 130C bed and 70C enclosure, and have the magnetic sensor in the front of your direct extruder. Splicing it in exterior make sense.

3.

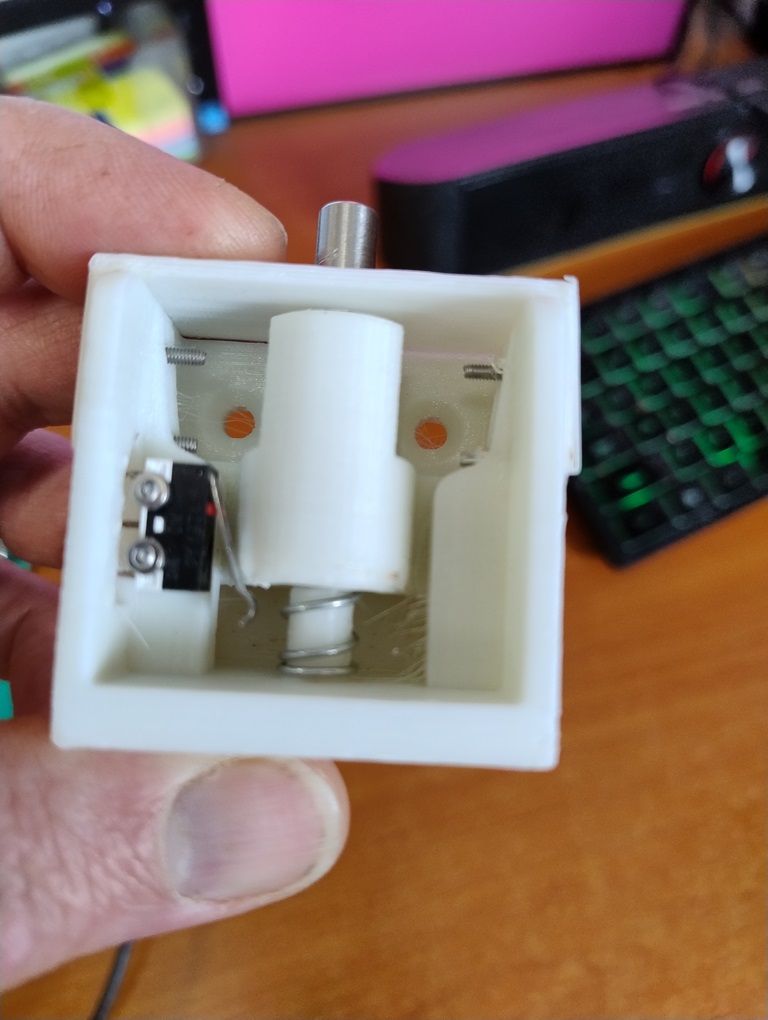

I also have another (3rd) filament sensor, wich is a simple gauge sensor, with microswitch and spring, as I had in the past some filament with MANY defects on it (bigger diameter, wich would clog the throat (nasty stuff, and when one passed, you think you are ok, restart print, go to sleep, and..., there are others waiting).

For it, trigger is a little different, as we do not want the head to move, but only to go up a little. Of course, it need adapted.

; trigger4.g ; called when filament is too big diameter ; M118 P2 S"Filament decalibrat" M118 P3 S"Filament decalibrat" M83 ; relative extruder moves G1 E-0.4 F1200 ; retract 0.4mm of filament G91 ; relative positioning G1 Z25 F360 ; lift Z by 25mm ;stay thereWill test these days.

Sensor body needs to be adapted for your switch, spring, etc, so it is not useful to post. However, it is very useful in practice, and I am sure most of you will do it much better, as mine is bulky (only it is not a problem for me). Oh, and I wonder, why I did not saw anything like this for sale...

4.

Finally, I am sure that Duet magnetic sensor works, with a very good enclosure, and maybe some firmware tweaking (talking about not needing such high sensivity).Hope these helps.