Homing failed, heating failed. Delta HC-250

-

We bought duet 3d board online from build3dprinter.eu. We received board on 2nd April, 2018 for our printer DELTA HC-250. we updated firmware to 1.21. now, We are facing the following problems. We read all the documentation & many forums regarding to this problem but nothing work.

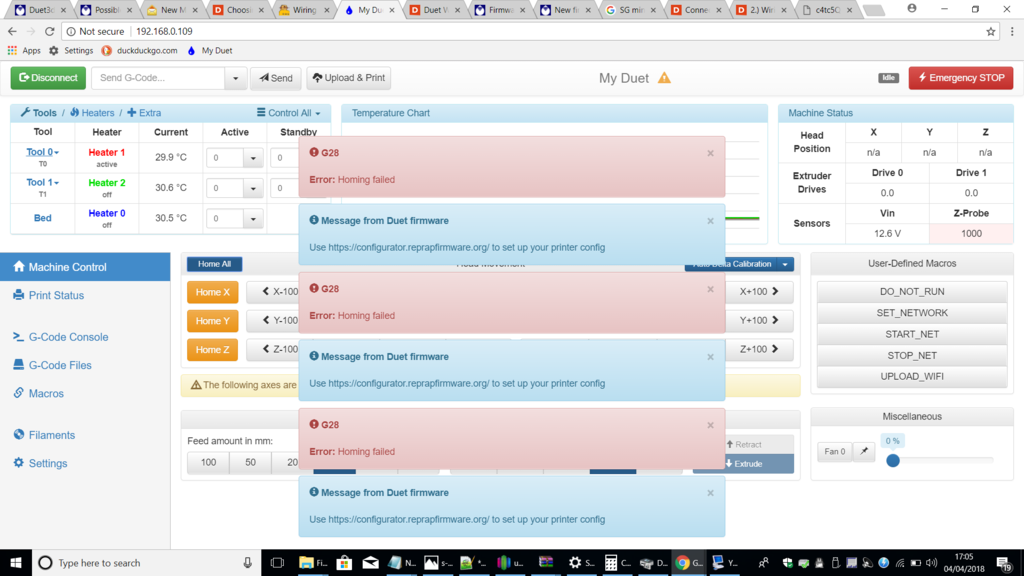

- The Printer homing command fails to execute. We are getting homing fail error.The motor dont move at all.

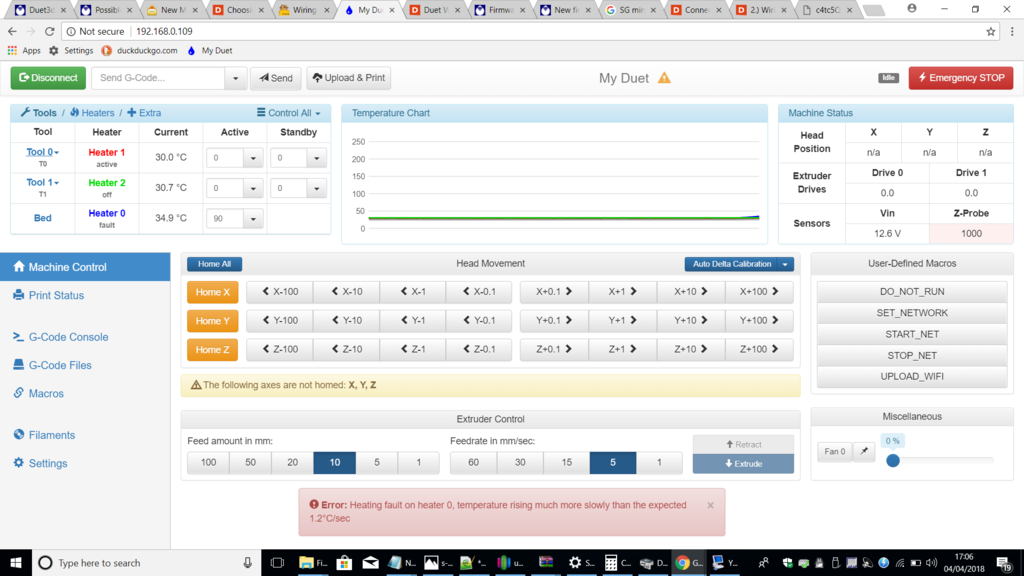

- While heating the heated bed after 30 temp. rise we get error message heating failed the temp. rise is lower than 1.20/sec.

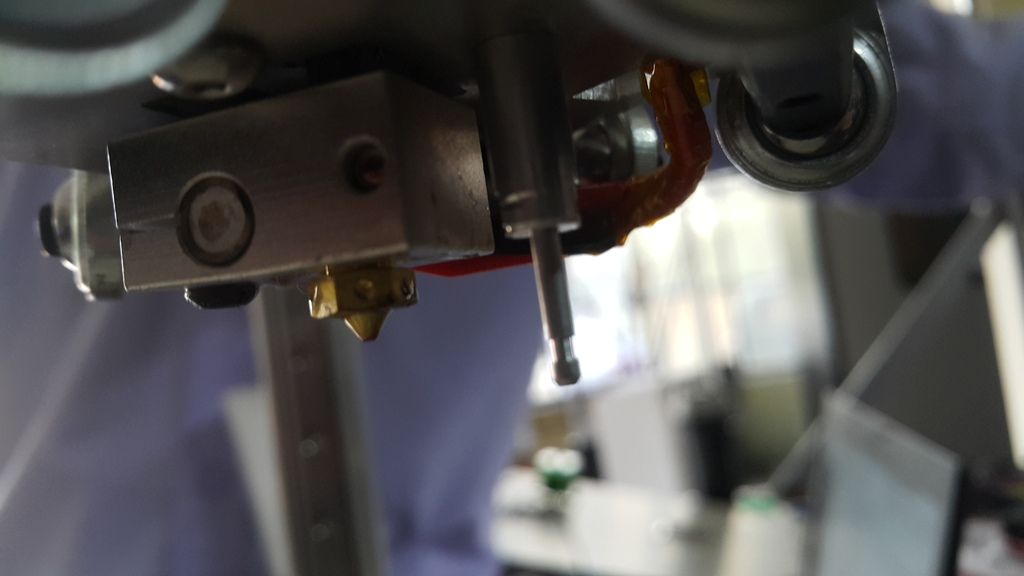

- also suggest us how to configure the probe.

config file

config file

; Configuration file for testing Duet Ethernet and Wifi with V1.19.2 firmware

FOR TESTING ONLY! USE https://configurator.reprapfirmware.org/ to generate configuration files for your printer!

; Communication and general

M111 S0 ; Debug off

M550 DELTAHC250 ; Machine name and Netbios name (can be anything you like)

M551 Preprap ; Machine password (used for FTP);*** Networking

M552 S1 ; Turn network on;*** Ethernet networking: Adjust the IP address and gateway in the following 2 lines to suit your network

M552 P192.168.1.14 ; (0 = DHCP)

M554 P192.168.1.255 ; Gateway

M553 P255.255.255.0 ; NetmaskM555 P2 ; Set output to look like Marlin

G21 ; Work in millimetres

G90 ; Send absolute coordinates…

M83 ; ...but relative extruder moves; Disable Fan 1 thermostatic mode

M106 P1 H-1; Axis and motor configuration

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M569 P4 S1 ; Drive 4 goes forwards

M574 X2 Y2 Z2 S1 ; set endstop configuration (all endstops at high end, active high)

;*** The homed height is deliberately set too high in the following - you will adjust it during calibration

M665 R105.6 L215.0 B85 H250 ; set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them

M350 X16 Y16 Z16 E16:16 I1 ; Set 16x microstepping with interpolation

M92 X80 Y80 Z80 ; Set axis steps/mm

M906 X1000 Y1000 Z1000 E800 I60 ; Set motor currents (mA) and increase idle current to 60%

M201 X1000 Y1000 Z1000 E1000 ; Accelerations (mm/s^2)

M203 X20000 Y20000 Z20000 E3600 ; Maximum speeds (mm/min)

M566 X1200 Y1200 Z1200 E1200 ; Maximum instant speed changes mm/minute; Thermistors

M305 P0 T100000 B3950 R4700 H30 L0 ; Put your own H and/or L values here to set the bed thermistor ADC correction

M305 P1 T100000 B3974 R4700 H30 L0 ; Put your own H and/or L values here to set first nozzle thermistor ADC correction

M305 P2 T100000 B3974 R4700 H30 L0 ; Put your own H and/or L values here to set 2nd nozzle thermistor ADC correction; Adjustments for Lite6 hotends used as dummy heaters on test rig

M307 H0 A250 C140 D5.5 B1

M307 H1 A250 C140 D5.5 B0

M307 H2 A250 C140 D5.5 B0; Fans

M106 P1 S-1 ; disable thermostatic mode for fan 1; Tool definitions

M563 P0 D0 H1 ; Define tool 0

G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures

;*** If you have a single-nozzle build, comment the next 2 lines

M563 P1 D1 H2 ; Define tool 1

G10 P1 S0 R0 ; Set tool 1 operating and standby temperatures

M92 E663:663 ; Set extruder steps per mm; Z probe and compensation definition

;*** If you have a switch instead of an IR probe, change P1 to P4 in the following M558 command

M558 P1 X0 Y0 Z0 ; Z probe is an IR probe and is not used for homing any axes

G31 X0 Y0 Z4.80 P500 ; Set the zprobe height and threshold (put your own values here);*** If you are using axis compensation, put the figures in the following command

M556 S78 X0 Y0 Z0 ; Axis compensation hereM208 S1 Z-0.2 ; set minimum Z

T0 ; select first hot end

M117 Use https://configurator.reprapfirmware.org/

This is a bl touch style probe but its deployed and retract is manually.

-

M122

=== Diagnostics ===

Used output buffers: 3 of 32 (10 max)

=== Platform ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 1.21 running on Duet WiFi 1.02 or later

Board ID: 08DDM-9FAM2-LW4S4-6J1DJ-3SJ6M-TJVZY

Static ram used: 16152

Dynamic ram used: 100800

Recycled dynamic ram: 1832

Stack ram used: 1224 current, 4400 maximum

Never used ram: 7888

Last reset 00:02:04 ago, cause: power up

Last software reset at 2018-04-04 17:43, reason: User, spinning module GCodes, available RAM 7760 bytes (slot 3)

Software reset code 0x0003 HFSR 0x00000000, CFSR 0x00000000, ICSR 0x0441f000, BFAR 0xe000ed38, SP 0xffffffff

Error status: 0

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest block write time: 0.0ms

MCU temperature: min 62.5, current 109.4, max 109.5

Supply voltage: min 0.5, current 12.6, max 12.7, under voltage events: 0, over voltage events: 0

Driver 0: standstill, SG min/max not available

Driver 1: standstill, SG min/max not available

Driver 2: standstill, SG min/max not available

Driver 3: standstill, SG min/max not available

Driver 4: standstill, SG min/max not available

Date/time: 2018-04-04 20:49:36

Slowest main loop (seconds): 0.014060; fastest: 0.000041

=== Move ===

MaxReps: 0, StepErrors: 0, LaErrors: 0, FreeDm: 240, MinFreeDm 240, MaxWait: 0ms, Underruns: 0, 0

Scheduled moves: 0, completed moves: 0

Bed compensation in use: none

Bed probe heights: 0.000 0.000 0.000 0.000 0.000

=== Heat ===

Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1

Heater 1 is on, I-accum = 0.0

=== GCodes ===

Segments left: 0

Stack records: 1 allocated, 0 in use

Movement lock held by null

http is idle in state(s) 0

telnet is idle in state(s) 0

file is idle in state(s) 0

serial is idle in state(s) 0

aux is idle in state(s) 0

daemon is idle in state(s) 0

queue is idle in state(s) 0

autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Responder states: HTTP(1) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0)

HTTP sessions: 1 of 8- WiFi -

Network state is running

WiFi module is connected to access point

Failed messages: pending 0, notready 0, noresp 0

WiFi firmware version 1.21

WiFi MAC address 5c:cf:7f:76:5f:f6

WiFi Vcc 3.28, reset reason Turned on by main processor

WiFi flash size 4194304, free heap 17032

WiFi IP address 192.168.0.109

WiFi signal strength -57dBm, reconnections 0, sleep mode modem

Socket states: 2 0 0 0 0 0 0 0

=== Expansion ===

- WiFi -

-

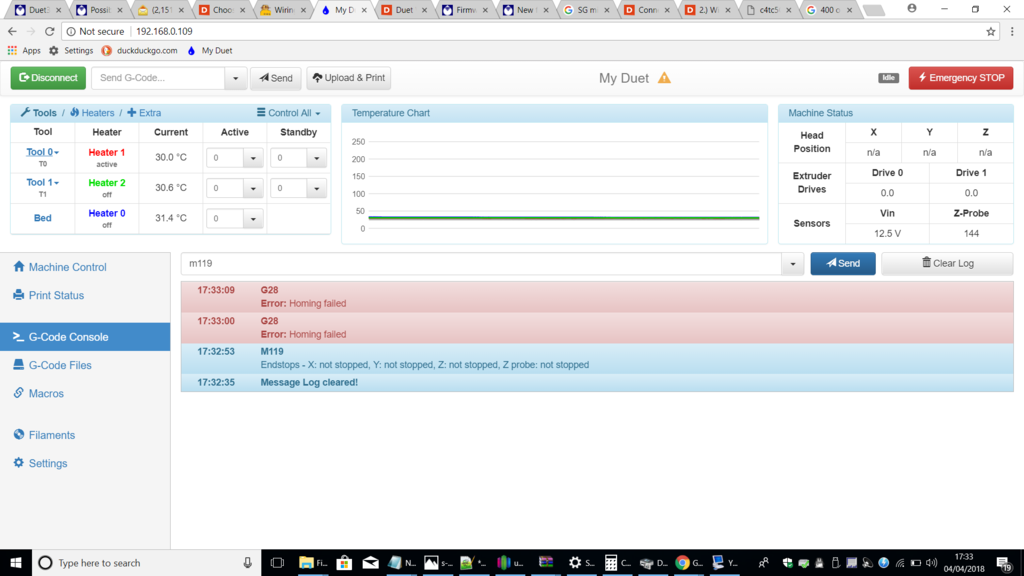

why does it show not available? how to solve this issue

Driver 0: standstill, SG min/max not available

Driver 1: standstill, SG min/max not available

Driver 2: standstill, SG min/max not available

Driver 3: standstill, SG min/max not available

Driver 4: standstill, SG min/max not available -

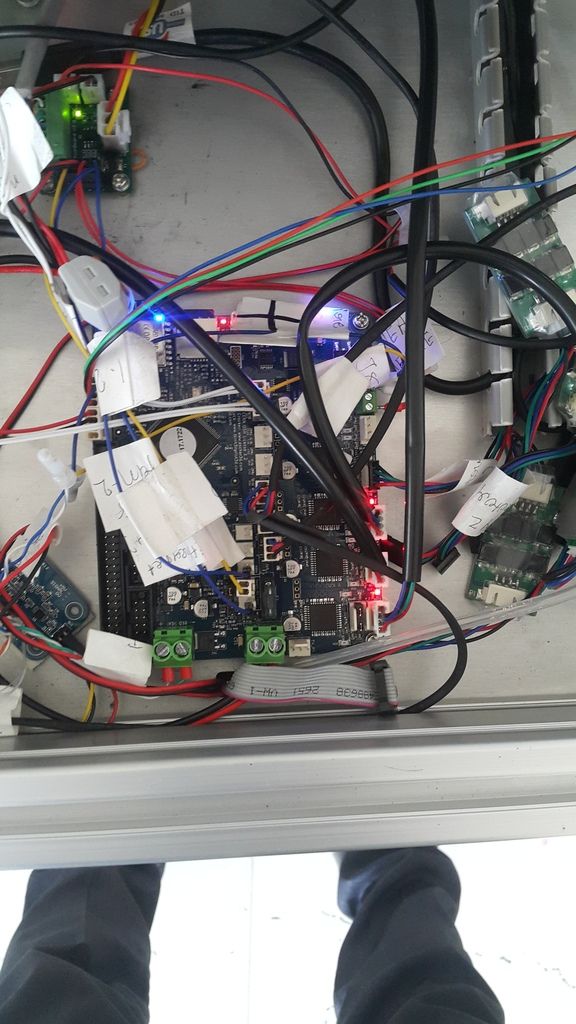

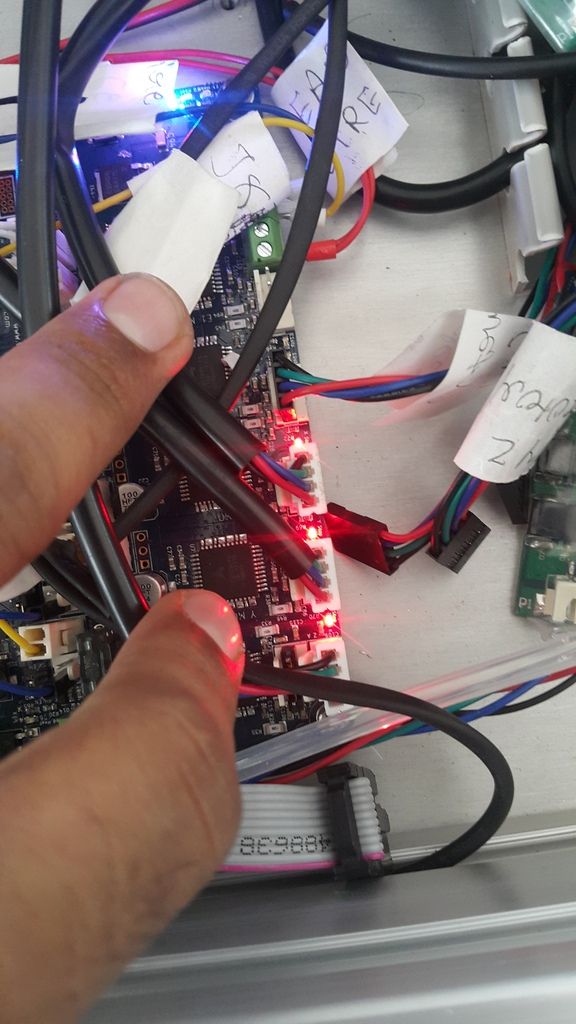

Your images are showing "3rd party hosting has been temporarily disabled" so I am not able to see them however:

1. Please test the motors individually as described at https://duet3d.dozuki.com/Wiki/ConfiguringRepRapFirmwareDeltaPrinter#Section_Testing_the_motors_individually. If the motors don't move:

- Send M906 to check that the motor currents are as you set them (XYZ all 1000mA). if they are all zero then config.g was not read from the SD card at startup.

- Check that the blue LED on the Duet is illuminated, indicating that you have VIN power to the Duet.

2. Heater temperature rise not as expected: tune the bed heater using M303. See https://duet3d.dozuki.com/Wiki/Spurious_heater_faults_and_how_to_avoid_them.

3. See https://duet3d.dozuki.com/Wiki/Connecting_a_Z_probe and https://duet3d.dozuki.com/Wiki/Calibrating_a_delta_printer. What type of Z probe do you have?

-

I hope you can see the images

-

The images were clicked by our phone and computer I don't know why it shows this message

-

No, I still can't see the images. This is a common problem with photobucket, I think you need to have a paid-for account for other people to see them.

PS - if you want to use Dropbox to host your images, replace ?dl=0 at the end of the Dropbox URL by ?raw=1.

-

Is it possible to send you the image through email

-

Please host them on imgur or dropbox. See https://www.csoonline.com/article/3205765/internet/photobucket-replaced-millions-of-images-with-ransom-demand.html for more about the photobucket issue.

-

Thanks for the advice will do it.

-

Also please post your homedelta.g file here as text, as you did with your config.g file.

-

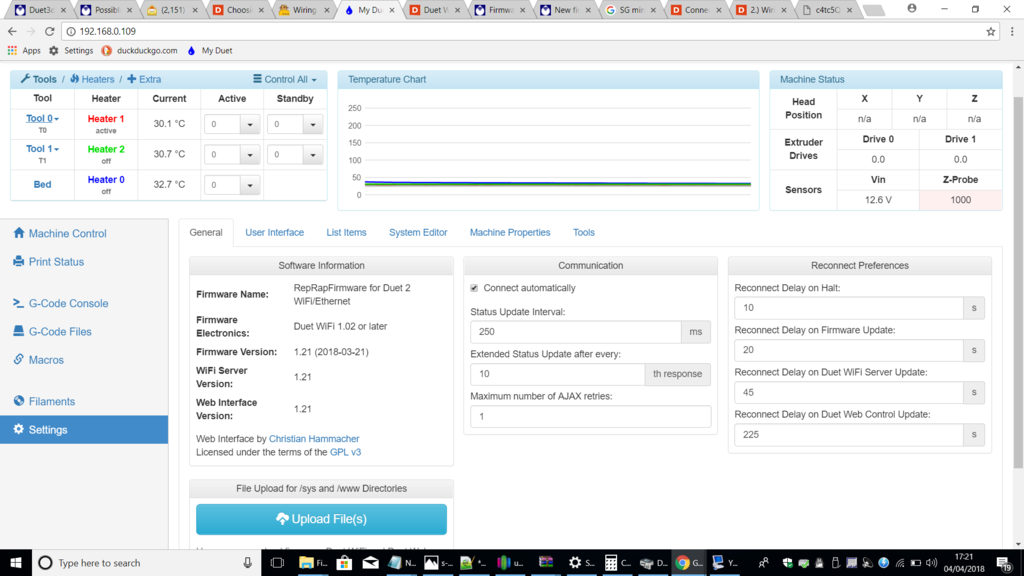

please check the images for more information.

image 1: https://www.dropbox.com/s/6f9cyjz5yapg6fx/1.png?dl=0

image 2: https://www.dropbox.com/s/btuo4v3rr9bbm56/2.png?dl=0

image 3: https://www.dropbox.com/s/ej00uy2vy4z6pu4/111.png?dl=0

image 4: https://www.dropbox.com/s/8s0gq0t6o3vecdv/4444.png?dl=0

image 5(connection): https://www.dropbox.com/s/ym6z2h2cjh7z1s1/20180404_160125.jpg?dl=0

image 6: https://www.dropbox.com/s/rrbxpl4cnmjnxgy/7.jpg?dl=0

image 7(Z probe): https://www.dropbox.com/s/6j265fm6p375g08/20180404_171502%20-%20Copy.jpg?dl=0 -

Thanks, I can see those images.

1. Homing failed: I still need to see the contents of your homedelta.g file.

2. Heating fault (temperature rising too slowly): see my reply yesterday, https://www.duet3d.com/forum/thread.php?pid=44742#p44742.

-

homing problem is solved the homing file had everything commented

Thanks -

The z probe always shows at min stop. The threshold value is shows 1000 and when triggered it shows 165 how to reverse this one ?

-

@JGR:

The z probe always shows at min stop. The threshold value is shows 1000 and when triggered it shows 165 how to reverse this one ?

Add parameter I1 in your M558 command. That's letter-i followed by digit-1. Better still, use the NC conrtacts of your switch instead of the NO contacts, which is safer if the switch becomes disconnected.

-

yes it solved the problem. Is it ok if we use 31865 board for PT 100 sensor with a reference resistance of 430ohms. I have read the instructions where it says use 400ohms Ref resister. we also have a Resister 391 ohms but have to replace that one on the board. we have also order the daughter board but it will take 2-3 week to reach our office. Is it possible to use 31865 board as we currently have in stock.

-

To use a PT100 board with a 430 ohm reference resistor, use parameter R430 in the M305 command that configures the heater to use that PT100 channel.

-

this is the new config file

; Configuration file for testing Duet Ethernet and Wifi with V1.19.2 firmware

FOR TESTING ONLY! USE https://configurator.reprapfirmware.org/ to generate configuration files for your printer!

; Communication and general

M111 S0 ; Debug off

M550 DELTAHC250 ; Machine name and Netbios name (can be anything you like)

M551 Preprap ; Machine password (used for FTP);*** Networking

M552 S1 ; Turn network on;*** Ethernet networking: Adjust the IP address and gateway in the following 2 lines to suit your network

M552 P192.168.1.14 ; (0 = DHCP)

M554 P192.168.1.255 ; Gateway

M553 P255.255.255.0 ; NetmaskM555 P2 ; Set output to look like Marlin

G21 ; Work in millimetres

G90 ; Send absolute coordinates…

M83 ; ...but relative extruder moves; Disable Fan 1 thermostatic mode

M106 P1 H-1; Axis and motor configuration

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S0 ; Drive 1 goes forwards

M569 P2 S0 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M569 P4 S1 ; Drive 4 goes forwards

M574 X2 Y2 Z2 S1 ; set endstop configuration (all endstops at high end, active high)

;M574 E0 S1

;*** The homed height is deliberately set too high in the following - you will adjust it during calibration

M665 R105.6 L215.0 B85 H322 ; set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them

M350 X16 Y16 Z16 E16:16 I1 ; Set 16x microstepping with interpolation

M92 X80 Y80 Z80 ; Set axis steps/mm

M906 X1000 Y1000 Z1000 E800 I60 ; Set motor currents (mA) and increase idle current to 60%

M201 X1000 Y1000 Z1000 E1000 ; Accelerations (mm/s^2)

M203 X20000 Y20000 Z20000 E3600 ; Maximum speeds (mm/min)

M566 X1200 Y1200 Z1200 E1200 ; Maximum instant speed changes mm/minute; Thermistors

M305 P0 T100000 B3950 R4700 H30 L0 ; Put your own H and/or L values here to set the bed thermistor ADC correction

M305 P1 X200 ; Put your own H and/or L values here to set first nozzle thermistor ADC correction

M305 P1 X200 ; Put your own H and/or L values here to set 2nd nozzle thermistor ADC correction

M305 P2 T100000 B3950 R4700 H30 L0

;heated chamberM141 H2 ; heater 3 is the chamber heater

M301 H2 B1 ; use bang-bang control for the chamber heater; Adjustments for Lite6 hotends used as dummy heaters on test rig

M307 H0 A250 C140 D6.5 B1

M307 H1 A250 C140 D6.5 B0

M307 H2 A250 C140 D6.5 B1 S0.5

M143 H0 S170

M143 H1 S410

M143 H2 S95; Fans

M106 P1 S-1 ; disable thermostatic mode for fan 1; Tool definitions

M563 P0 D0 H1 ; Define tool 0

G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures

;*** If you have a single-nozzle build, comment the next 2 lines

M563 P1 D1 H1 ; Define tool 1

G10 P1 S0 R0 ; Set tool 1 operating and standby temperatures

M92 E663:663 ; Set extruder steps per mm; Z probe and compensation definition

;*** If you have a switch instead of an IR probe, change P1 to P4 in the following M558 command

M558 P4 X0 Y0 Z0 F100 I1 T2000 H15 ; Z probe is an IR probe and is not used for homing any axes

G31 X0 Y18 Z2.80 P500 ; Set the zprobe height and threshold (put your own values here);*** If you are using axis compensation, put the figures in the following command

M556 S78 X0 Y0 Z0 ; Axis compensation hereM208 S1 Z-0.2 ; set minimum Z

T0 ; select first hot end

-

All the heaters are fluctuating more or less 5C even after auto tuning. The Chamber behaves a little wired sometime it gives the temperature rise error and some time it doesn't. please guide us through right procedure.

Also during bed levelling, While clicking at the UI Autobedlevel button it will take all the points correctly , but if we give the g32 command the head will move outside the bed size to take the points.