Stop print on motor unplug

-

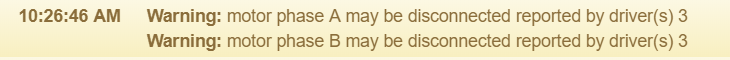

I ran a print over a few hours and when I returned to the printer I noticed that it had stopped extruding. I found that the extruder motor had somehow been unplugged during the print. I found that this error was shown repeatedly and was able to reproduce it this morning.

However, the print does not stop printing when this warning is shown. Is there anyway to pause the print when this occurs? -

A filament sensor (that detects movement as well as presence) would achieve the desired result.

If its possible to use the warning directly or if its something that can be added to future versions is something the developers can address maybe.

-

I would strongly advise not trying to reproduce this error anymore, unplugging motors while they're running is a great way to burn out a driver.

-

This is a good feature request or even a bug fix.

Clearly if a motor has disconnected it should pause. Perhaps continue until the next gcode that requests a move on thay axis and pause - this would save lost builds on multi extruder systems where there was mo need for the extruder that faulted.

-

Facilitating recovery in firmware encourages dangerous behavior like pointed out, hot plugging motors isn't recommended despite the Duets seemingly being more rugged than most other control boards. Stop, okay, pause, not sure thats a good idea, but I recon there are higher powers with more knowledge to descide.

Secure the cables in the first place, if a cable breaks you'd want to shut down the machine to make repairs and not have the firmware encourage working on it live imo.

-

...may be disconnected... According to Trinamic data sheets, this detection sometimes yields false positives. I don't want a pause on a false positive.

And... as stated over and over, a real disconnect while the motor is turning is almost certain to blow the driver on older drivers. (I am unwilling to experiment with Trinamics. ) Therefore, as mentioned, messing with cables with power on = bad bad bad.

Given all above, no pause for me!!

-

Just to be clear I am not endorsing yanking cables about with the system powered.

Do the drivers lock a fault flag or only hold it temporarily while it thinks the fault is present? The duet may keep a pop up warning active for longer than the fault exists to warn of pending failure. If the fault flag doesn't lock then a fault must exist for x seconds before pause may catch most false posatives.

Main use case for this is capturing failures in highly dynamic power cables such as direct extruders and serial manipulators such as cartesians where the x axis stepper is moved for a change in y.