Laser Gcode S Sticky after G0 question

-

Thanks for both your replies.

An S2 option would help me out would only mean changing the first 5lines or so lines of the gcode.

As for lightburn it can output many controllers.

Grbl

Ruida

Marlin

Trocen AWC 608 and 708c

Smoothie

Maybe more than this.I use smoothie config as it seems to be the closest to what is needed.

Greyscale Images work well as there is S on every G1 line. -

@mikeisamonk

I've been looking for an excuse to trial LightBurn, so I just had a play; It's a pretty good tool. I might even splash $40 on this for myself.But not adding

Sparameters to every initialG1when cutting vectors (as opposed to ditering and grayscale) is most annoying. It would help if the Duet could have a less-safe 'on while in motion' option to M452 for this case.I found this:

https://forum.lightburnsoftware.com/t/how-to-make-the-software-add-sx-to-the-end-of-the-first-g1-line-after-m3-sx-in-a-cut-operation/6551

Where they recommend using the GRBL-M3 (non lasermode) profile; but having done some quick testing I do not think it would help for this problem; it will just fill your code with lots ofM3/M5's, without adding theSparameters where needed.Edit: Of course; you could select the GRBL-M3 mode, edit the header but leave lasermode OFF; and make darn sure you don't set anything on fire.. but it is a bad recommendation. Ok.

-

I do really like lightburn it also has good support well worth the money imo, I also have a k40 with C3D (smoothie) controller which is brilliant the problem is the space inside the k40 is limited.

With the laser attached on the 1m² CNC mill I can engrave any ply I cut.I did try all of the different firmware outputs but the smoothie option seems the closest. (Might be biased as I'm more familiar with it).

If the S2 option can't be implemented I will try writing a script to post process the gcode automatically.

Mike

-

I just got my laser working on my printer. If you are ok with buying a program PicEngrave will produce the correct gcode.

https://www.picengrave.com/PicEngrave_Pro_6_+_Laser.htm

It will let you decide if you want the Sxx on the same line or on seperate line. It will also let you dictate what M code will control the laser (M106 or M3 etc.) -

I am also interested in getting lightburn to work with the Duet. I have attatched a CO2 laser tube onto the gantry of my CNC router. Currently I use machinekit to drive it as it has support for 3d printing head that I use sometimes.

I would like to use the duet for its ease of use and its ability to sync dual z axis and y axis motors. It also supports bed leveling which machinekit does not. I would like that very much as mesh leveling on a 6'x4' bed can be very useful for keeping the nozzle and laserhead at the correct height.

From what I have read, lightburn is not currently supported. I would still be waiting on the duet 3 to push my nema 23 motors though. Is there plans to support lightburn's gcode in the near future?

-

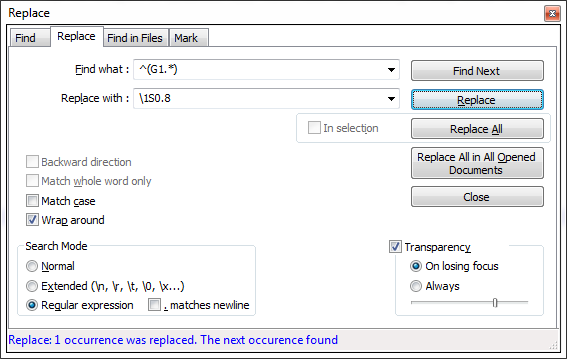

At the moment I am loading gcode In notepad++

It should add an S value on all lines starting with G1

This is only good if your using 1 level of power.Mike

-

@mrsolis93 said in Laser Gcode S Sticky after G0 question:

Is there plans to support lightburn's gcode in the near future?

It may be a better idea to ask the same of the LightBurn people; they could support Duet as a controller; add a more appropriate header to the code and a S parameter to every active G command.

Even if Duet solves the resume problem andsupports persisting the level from cut-to-cut, the gcode preamble (headers) will still be wrong.The LightBurn developers have made a decision not to support custom headers and commands. The available devices (controllers) are in a dropdown; and they just offer a few options on a per-controller basis. Duet is not in that list, so you will always need to post-process, until they add it

I understand their reasoning (avoiding some support and 'you broke my machine' hassles), but it does mean they need to be proactive in supporting popular controllers.

From my perspective this is ok since it's grbl-laser support is perfect and I'm using grbl-esp32 in my engraver. I'm going to give it a go since it's cheap and probably makes a great alternative to my current free open source toolchain, aka InkScape and LaserWeb4.

-

I've made a change to the source code to preserve the laser power across G0 commands. It will be in the 2.04RC3 release. I've done the build already, but I won't have time to test it until Wednesday.

-

@dc42 thanks for the update.

Going to save me a lot of post processing.

-

@EasyTarget

What headers are necessary for the duet to run lightburn?Wouldnt it be possible to just write a lightburn header Macro? I would have to use headers anyway for autoleveling since laser cutters don't usually support that anyway.

-

@mrsolis93 said in Laser Gcode S Sticky after G0 question:

What headers are necessary for the duet to run lightburn?

I dont really know.. not using my Dued for my CNC work I've never investigated; but if you look at the example given by @mikeisamonk in the OP you can see the sort of preamble that is needed.

Wouldnt it be possible to just write a lightburn header Macro? I would have to use headers anyway for autoleveling since laser cutters don't usually support that anyway.

It would indeed, the core problem being that LightBurn has nowhere to enter the header. So you'd need to post process, or persuade it's developers to add the Duet and support all the M307,452,571 combinations people might need.

-

@mrsolis93

This is what I use. This is slightly different to the above code the max output is set to 1.00 as lightburn outputs from 0-1 when smoothie hardware is selected.What laser are you using?

I had to invert and convert the ppm signal from 3.3 to 5v for my diode laser.G00 G17 G21 G54 G90 M307 H3 A-1 C-1 D-1 ; Disable Heater output on H3 M452 P3 S1 R1.00 F2000 ; Enable Laser mode, on output 3 (heater 3), with max intensity being 1.00, and a PWM frequency of 2000 M571 P3 F200 S0 M3Mike

-

Thanks for the header information!

I am using a 60w CO2 laser tube and power supply from amazon. Also picked up a mirror/lens kit to bounce it all around my CNC router.

I am still playing with it and determining whether it is worth it to keep it on my machine or move it to a separate one. Part of that is finding a board that will support all the different tasks.