How does an overheated drive present? v0.6 board.

-

Morning All,

Having a real difficulty in an area of a part that I thought was one of the simpler bits of it!

I'm getting skipped steps that show as a layer shift. By the time I spot the layer shift the machine has normally done a few more layers, and so if it is a part curl/overbuild issue it has already been hidden.

I was wondering what a thermal shut down drive would look like? If the thermal protection kicks in and then recovers without a reset I was expecting the layer shift to be much more than 0.5mm or so?

Board is a v0.6 with a shield. Running a P3Steel with dual drive z.

Most recent failures occurred 6.5 and 5.5hrs into their prints.

I'll add current setting shortly.

-

No one got a clue what happens when the drive goes into thermal protection then?

My gut feeling was that it would shut down for longer than just a skipped step and make quite a mess. Likewise I was assuming that the first generation boards don't return an alarm message if the driver dropps into thermal protection.

-

@DocTrucker As far as I remember from the 'old days', there's no warning generated about overheating as it's not monitored, the driver will just skip steps until it cools down. I managed to do this a few times on RAMPS boards, and they tended to stutter and lose a few steps, but then carry on with the pauses getting longer and longer if they continued to heat up. But I can't remember it happening on Duet 0.6 - never needed to drive them that hard.

If you think it's overheating, best to fit the board vertically and have a fan that blows on both sides of the board. Stick on heatsinks don't do much from what I remember; clone boards come with them for added bling!

Ian

-

Thanks!

I think it's the head hitting something. Either that or a short sequence of vectors are causing resonate and skip a step. If it was going to skip steps due to dropping into thermal protection it would be unusual for it to go for so long without skipping and then just miss one step?

-

@DocTrucker said in How does an overheated drive present? v0.6 board.:

If it was going to skip steps due to dropping into thermal protection it would be unusual for it to go for so long without skipping and then just miss one step?

Yes, I'd think that would be unusual. More likely to be collision/sticky axis/resonance (though I'd be surprised at that if you've got the current turned up high) or possibly just motor settings set just a bit to aggressively.

Ian

-

My current acceleration setting is aggressive, but the way I understand the DAA (dynamic acceleration adjustment) feature it is supposed to be high and let the DAA sort it out. That said I'm running up against it on what should be a simple print (alas with supports) and so I will look at dropping X/Y axis acceleration by 10% or so.

Don't like doing loads of changes at once but no time left to do it properly!

-

I don't think DAA is to stop your acceleration going too fast; it's for avoiding specific frequencies. See https://duet3d.dozuki.com/Wiki/Gcode#Section_M593_Configure_Dynamic_Acceleration_Adjustment

Ian

-

Current:

M906 X1200 Y1200 Z1200:1200 E1250Accelerations:

M201 X1800 Y1800 Z250 E3600Going to drop the latter to:

M201 X1600 Y1600 Z250 E3600(12V)

-

I wouldn't have thought 1.2A would overheat. The Duet sinks heat better than the RAMPS type plug in drivers, which I think I got to overheat at 1.5A.

Ian

-

Thanks fella. That's what I suspected but was beginning to doubt myself.

Another candidate was the Gyroid infill was never reaching requested speed. I doubt it but wonder if things got a little weird on the extrusion.

-

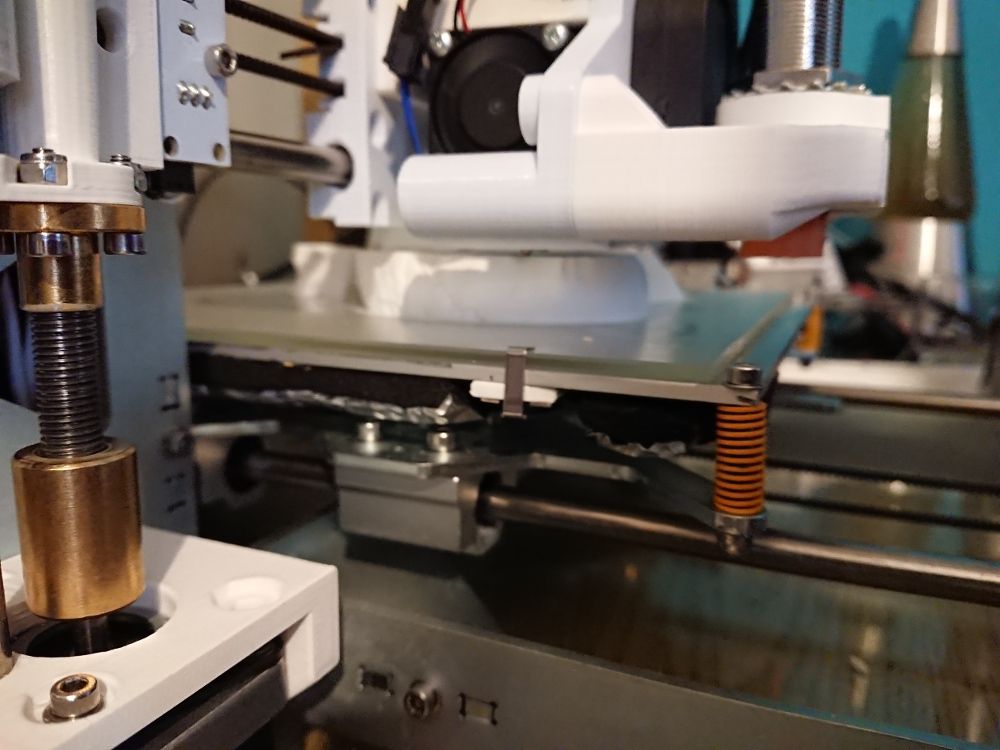

I hope I have finally got to the bottom of this issue! It appears as if the glass bed on my machine was slipping.

I'd used picture clips like on the Ormerods to secure the glass bed to the heated bed. On my most recent build I didn't have one of the MDF insulators that went on the back and so bought some stick on foam insulation instead. I cleared the foam where the clips went and thought the clips held well enough. I may have been wrong!

Running a build with an extra spacer on all of the bed clips and it is looking a little better already.