What kind of servo motor are recommend connect to duet 2 wifi?

-

Hi All expect, I'm new in this forum.

Here some question need to ask:

- What kind of continuous (360 degree) high torque servo motor are recommend connect to duet 2 wifi?

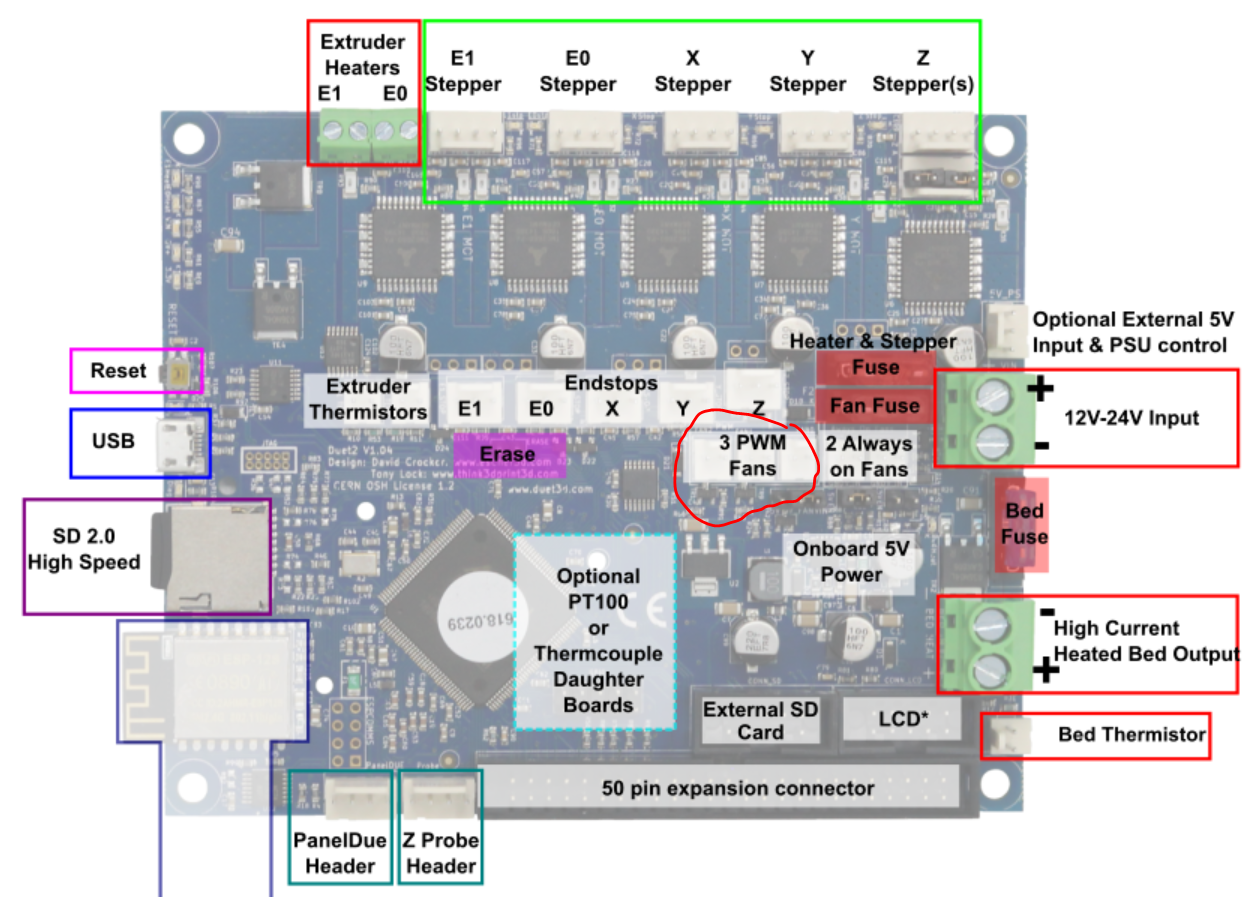

- PWM 3 pin connector is for servo motor also?

- If used 5v on the PWM connector, can it work for servo motor?

- Only gcode can control the servo motor position?

-

@daxzero said in What kind of servo motor are recommend connect to duet 2 wifi?:

Only gcode can control the servo motor position?

Can't control position of continuous rotation servo, only direction?

-

@bearer sorry, what you mean?

-

@daxzero said in What kind of servo motor are recommend connect to duet 2 wifi?:

- What kind of continuous (360 degree) high torque servo motor are recommend connect to duet 2 wifi?

- PWM 3 pin connector is for servo motor also?

- If used 5v on the PWM connector, can it work for servo motor?

- Only gcode can control the servo motor position?

Traditional hobby servos use pulse width input to specify a position. Pulse widths in ms: 1000 is all the way one way, 2000 the other way, 1500 ms is generally centered. So, say, 1250, would position it about halfway between center and end of movement.

Continuous rotation servos use pulse width input to specify rotation speed. Pulse widths in ms: 1000 is rotating at full speed one way, 2000 rotating the other way, 1500 ms is not moving. So, say, 1250 would have it continuously rotating at about half of top rotation speed.

I.E. Nothing to do with Duet... continuous rotation servos cannot be positioned (via their pulse width input).

-

Yeah

Maybe you can elaborate a little on your use case to get some ideas?

-

@Danal i want to make a tool changer with 7 extruder, so looking for a servo motor that can control each different position of the 7 extruder.

if not continuous servo motor, which servo motor can do for this?

-

@daxzero said in What kind of servo motor are recommend connect to duet 2 wifi?:

@Danal i want to make a tool changer with 7 extruder, so looking for a servo motor that can control each different position of the 7 extruder.

if not continuous servo motor, which servo motor can do for this?

By "toolchanger" do you mean a rotary tray (like a big commercial CNC machine) or do you mean an E3D/Jubilee style "pick up and park tools"?

-

@bearer i want to make 7 extruder tool changer.

-

OK, then you don't need servos at all.

The carriage has a tool lock driven by a stepper motor that lock/unlocks a tool. Macros are auto-invoked by the Duet firmware when it sees a T0 or T1 or whatever, and those macros position the carriage, lock a tool, or park and unlock a tool, or whatever.

All done with the XY steppers and the tool lock stepper.

Watch the video, and you will see a Jubilee pick up a tool and print with it.

At about 45 seconds, it parks the first tool and mounts a different one. The in/out motion on pickup is wiping the nozzle on a fixed strip of silicone just below the parking stall.

-

More info on the Jubilee:

https://github.com/machineagency/jubilee

It is one of the better toolchangers out there, right now.

-

@Danal said in What kind of servo motor are recommend connect to duet 2 wifi?:

E3D/Jubilee style

rotary style.

-

@Danal i see... i prefer rotary motion because it just move directly like the clock. Example clock at 1 pm is E1, 2pm is E2 and same to others extruder position. So it will take less than time to change to another extruder.

-

Okay, you will still not be able to control a continuous rotation servo to a specific location. You might be able to find a 360 degree servo but it will not be a continuous rotation servo. However a stepper motor may be easier and smoother as you can control acceleration and jerk.

-

@bearer so which brand or model of 360 servo motor are recommend to used in duet 2 wifi board?

-

@daxzero said in What kind of servo motor are recommend connect to duet 2 wifi?:

@bearer so which brand or model of 360 servo motor are recommend to used in duet 2 wifi board?

The reason why nobody is answering that is: Almost any of them. All servos that take 1000 to 2000 ms pulses will work. Which is 99% of them.

So choosing the servo has almost nothing to do with the Duet. You need to choose it based on torque, speed, positioning accuracy, rotating vs. positional, whatever you need. The Duet will drive it.

Oh, and I strongly agree with @bearer, a stepper motor is a MUCH better choice to drive a rotary tool changer table, as vs. a servo. As he said, accel, speed, decell will be important to moving that much mass, and a Duet driven stepper does that as a base function. Servos don't.

-

@Danal Ok. Can i used gcode to control stepper motor for rotary tool changer table?

-

@daxzero said in What kind of servo motor are recommend connect to duet 2 wifi?:

Can i used gcode to control stepper motor for rotary tool changer table?

just set up the steps/mm as steps/degree and use it like any other stepper

-

you mean yes and able to do that on slicer, right?

-

@Danal i just want to know more about servo motor and what happen if i do it.

the red circle highlighted is also used to servo motor right?

if yes, then can i used gcode to control it? -