Trouble with Auto bed levelling

-

Before I start, I am certain this is not an issue with the Duet or likely even the settings on the Duet firmware, I think this will be a mechanical issue but I can't work it out so am running it by people much better than this than me!

I have been trying to get my printer to be able to level the X axis automatically with a macro as sometimes the Z motors can get a little out of sync, requiring me to manually get the X axis level. I am sure that the macro is working correctly but the sensor seems to think the bed is tilted when it is actually level. I have checked that the X axis rods is level to the printer frame/extrusions.

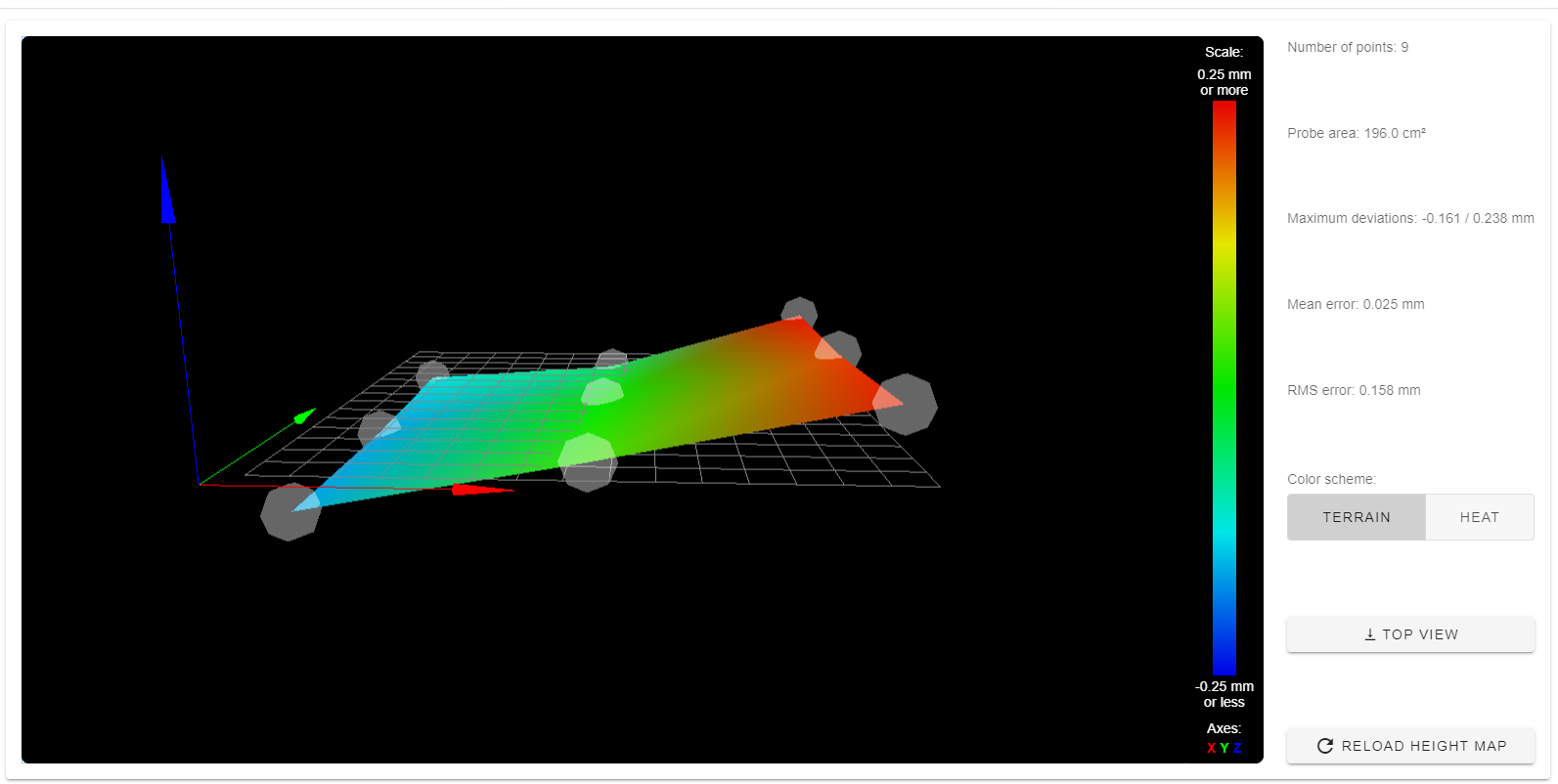

Here is a photo with a bed level test and also a screenshot of a 9 point test taken straight after. I can repeatably get this slanted result when the bed is levelled. Also, If i get the macro to level the X axis the 9 point shows it flat but the nozzle is not flat to the bed and the X axis not square to the printer frame.

The sensor is a BL touch clone, which I guess could be the issue but I am getting repeatable results, I also have the sensor setup for 0.02mm tolerance so it will only accept the result if its within that.

So where I am stuck and wondering if anyone may have a clue, is that it seems that the sensor thinks the bed is slanted and yet the nozzle is correct. I'm just really not sure what this really means and how to fix it, anyone got any ideas? I suppose maybe my printer's frame is not perfectly square but I would have thought the nozzle and probe should be relative to each other so if one is level the should be too.

X gantry for reference:

Thanks! -

Hy,

i have an idea for you .

Measuring the Distance between underside of the lower X-Axis rail to the top of the right y-Axis Rail.

Then measuring at the left side again !it looks like there is a difference in measurement

Ideally Use an gauge block

or an industrie measuring stickis this exact the same ?

Best regards Marco -

Thanks for the idea.

I have tried measuring with Digital calipers the distance between bottom of X rod and top of Y and ended up with L=66.68, R=66.8 and also top of X rod and bottom of Y rod L82.7 R82.77 which is off but not considerably and I don't really trust I can measure very accurately.

What I have noticed though is that the distance between the two X rods is 36.88 on the far left and right but nearer to the X carriage it goes to up to as high as 37.3 so I think the X carriage bearings are not spaced correctly and stretching the rods apart. So that could be it. though if this was affecting the levelling I would have thought it would be a curve along X rather than a slant consistent the whole way.