Will a fluctuating extrusion rate cause step errors?

-

I'm trying to figure out what causes the GCode from IceSL to generate no hiccups, and 1 single unerrun, while the Gcode from PrusaSlicer of the same model, with as-close-as-possible settings, produces many more underruns and a hiccup that I think caused a HUGE blob of filament to extrude into a support tower (which caused the nozzle to hit it and knock the support tower over).

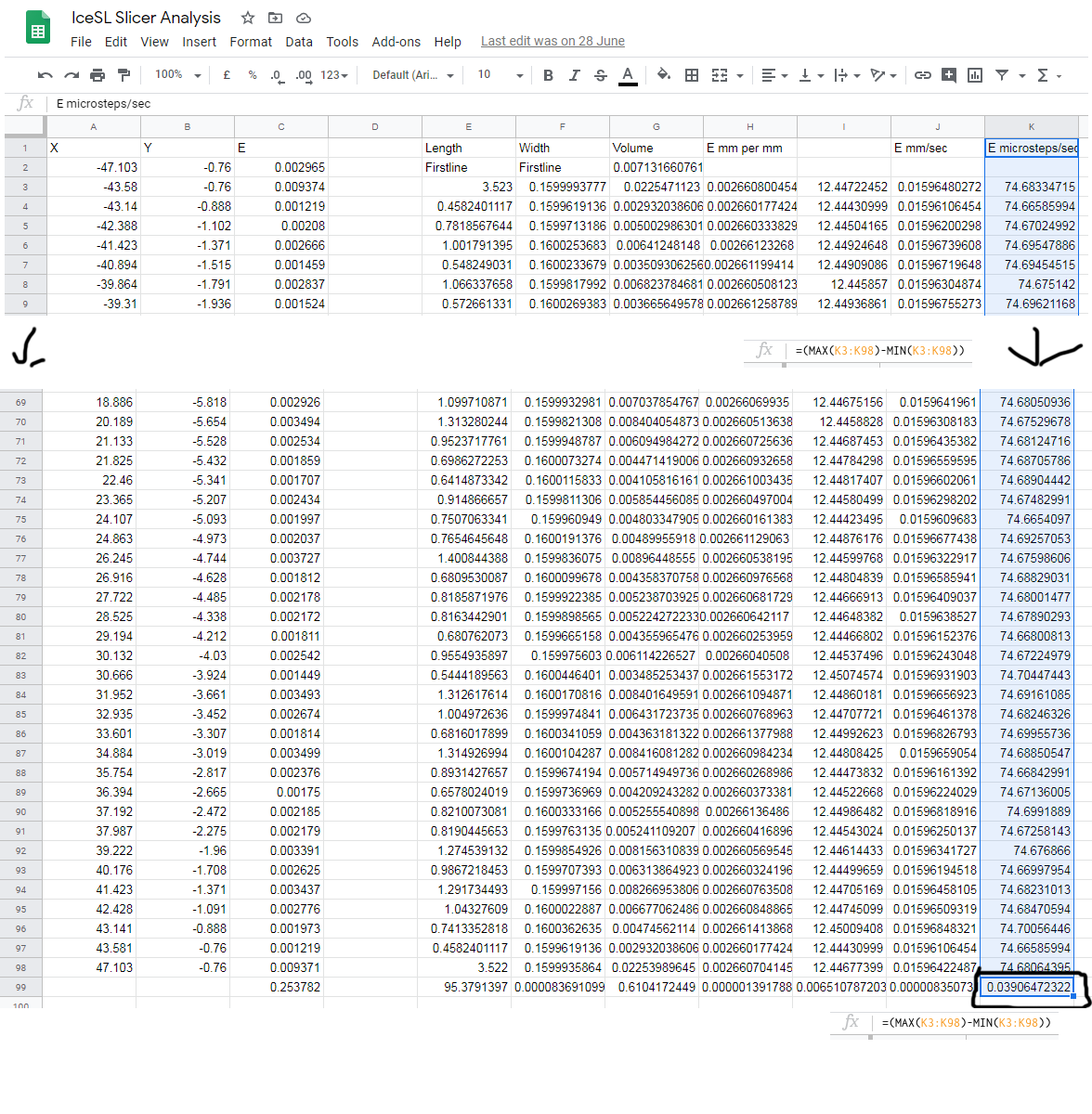

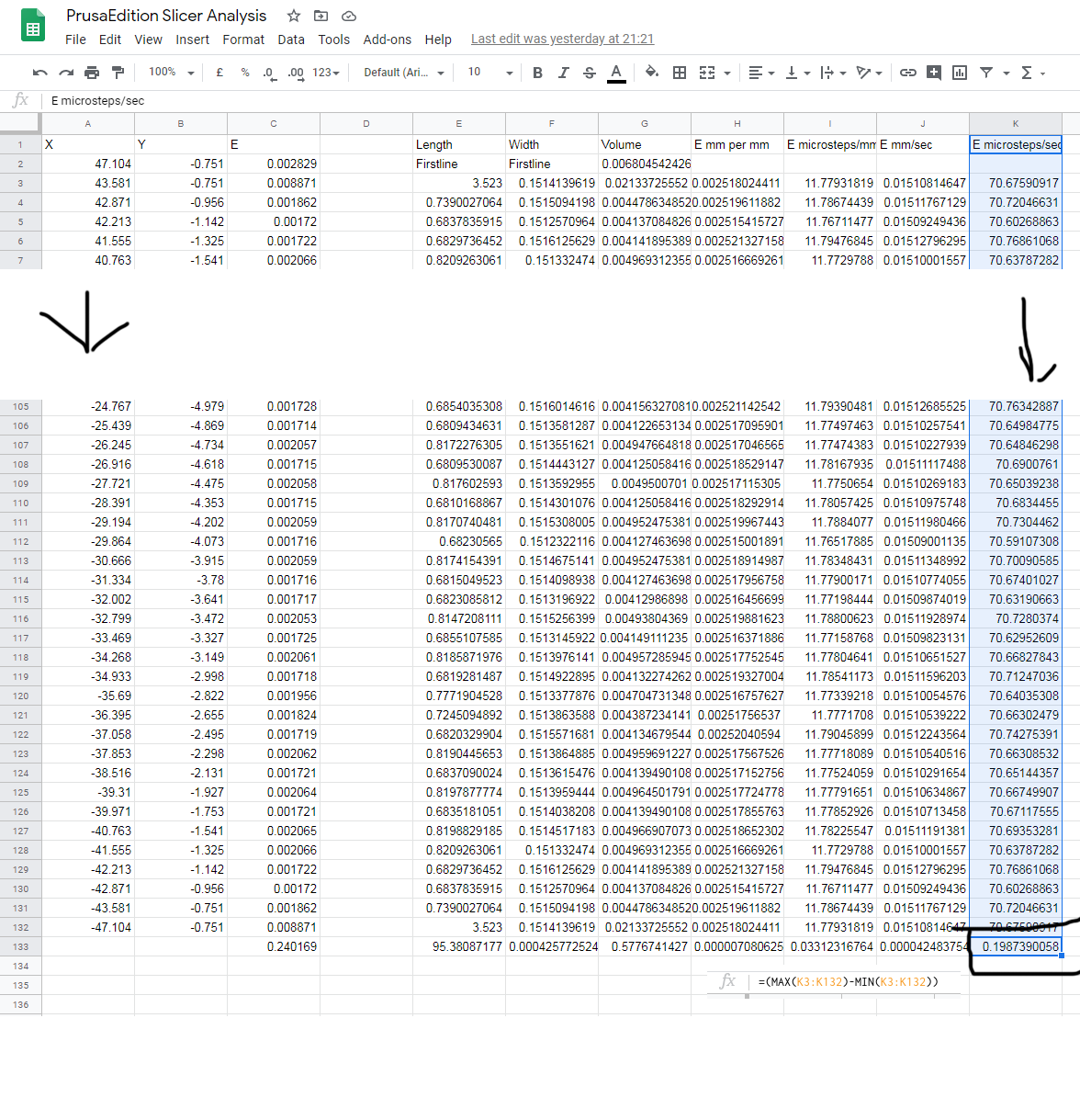

See these analyses of the two slicers:

Might that be my problem? Or, is it more likely related to the actual toolpaths they generate -- perhaps the support structure or infill is generating these underruns/hiccups?

-

Assuming you are printing from SD card, underruns should be rare. It's normal to get one at the end of a print. Otherwise they are normally caused by printing from a PC over USB instead of from SD card, or the GCode model containing a long sequence of very short segments.

Hiccups are usually caused by the product of microstepping and maximum speed being too high.

-

I'm printing from SD card. This GCode does have lots of small segments, but only on the perimeters and they are printed at 6-12 mm/s.

The problem areas seem to be the infill or support, which are merely rectilinear with small zig zags.

But actually, now that I think about it, the dense support structures from PrusaSlicer draw loops that conform to the curve of the model. This could be it, since I was printing the supports lightning fast with PA enabled.