Inconsistent results with optical encoder wheel filament sensor

-

@arhi said in Inconsistent results with optical encoder wheel filament sensor:

the interrupter on those boards require pullup, wether pullup is already mounted on the pcb with the interrupter or not I don't know but testing with pullup on the duet is simple so nothing to lose by trying it IMHO

I added the pullup. Results seem more consistent. Still a broader range than I'd hope for a vase mode cylinder. I'll tweak the settings a bit - perhaps increase the measurement length, and try again.

Pulse-type filament monitor on pin (connlcd.encb,connlcd.3), disabled, sensitivity 1.200mm/pulse, allowed movement 50% to 1500%, check every 5.0mm, measured sensitivity 1.368mm/pulse, measured minimum 28%, maximum 428% over 521.3mm -

@JohnOCFII Sadly - continued testing shows similar wild results:

Pulse-type filament monitor on pin (connlcd.encb,connlcd.3), disabled, sensitivity 3.000mm/pulse, allowed movement 30% to 1500%, check every 10.0mm, measured sensitivity 1.731mm/pulse, measured minimum 72%, maximum 2606% over 1026.4mmI had changed the pulse sensitivity to be closer too what the measured results were on the previous tests, but now it moves again.

-

dunno that sound really bad, maybe move the connection to the

C"^e0stop"connector, dunno if it makes a difference but I'm not getting that big span on that pin -

If you can get that BitScope DSO to run I think that's a good way to move forward. Dunno if it's capable of "passtrough" grabbing like saleae, that would be ideal...

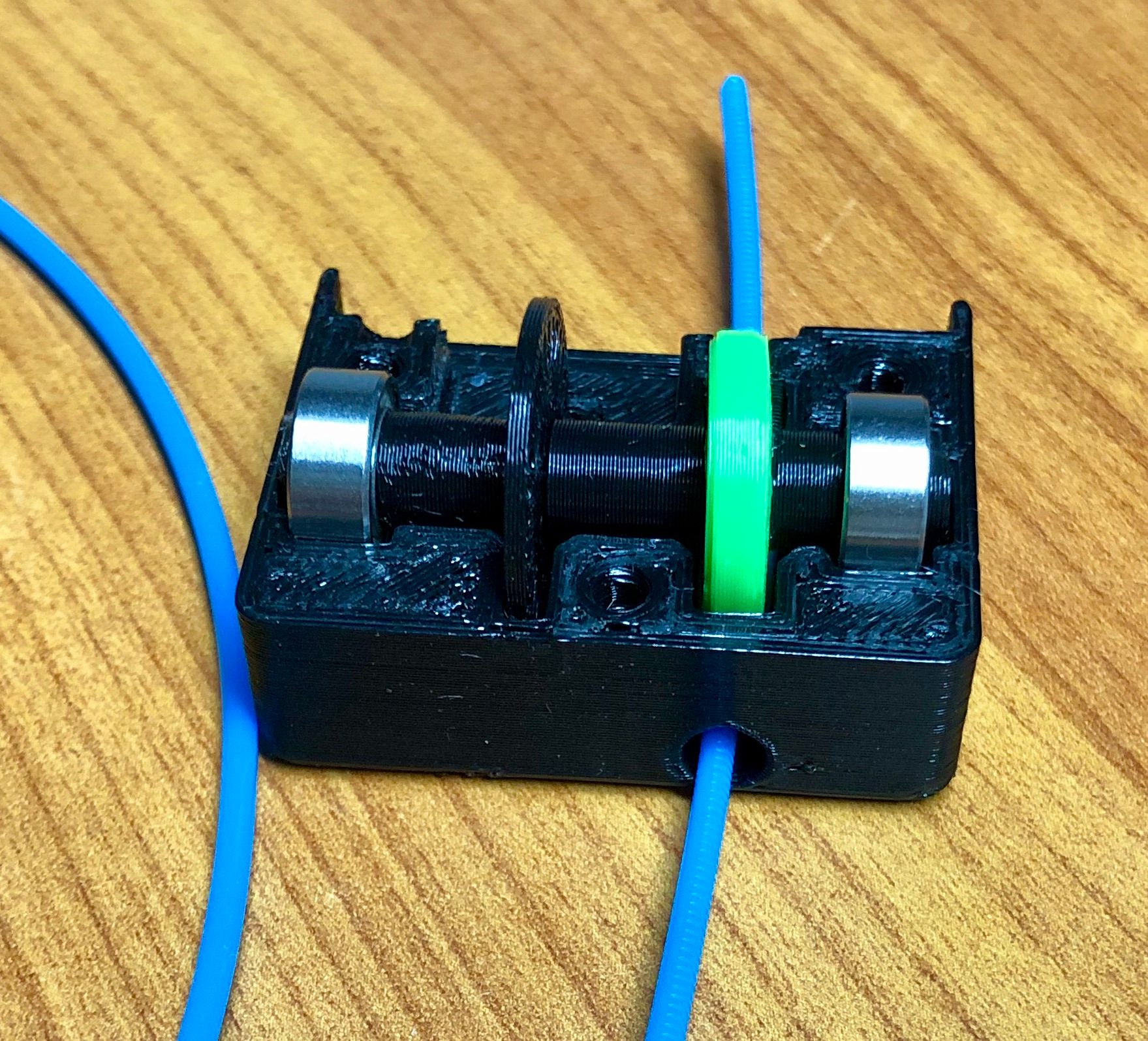

What is the interface material between the roller and the filament? And how is filament pressed to the roller? I was having a lot of slipping when my roller wheel was just a piece of PLA/ABS and since I didn't have any real flex to print it out of I made a roller wheel to have groove and added a small wide rubber band (I actually redesigned my sensor to fit that rubber band

and that's the only small one I have, when it wares out I'll have to figure something new)

and that's the only small one I have, when it wares out I'll have to figure something new) -

@arhi said in Inconsistent results with optical encoder wheel filament sensor:

dunno that sound really bad, maybe move the connection to the

C"^e0stop"connector, dunno if it makes a difference but I'm not getting that big span on that pinThat'd be wild if a different connection made a difference. I'll have to think about that.

-

@arhi said in Inconsistent results with optical encoder wheel filament sensor:

If you can get that BitScope DSO to run I think that's a good way to move forward. Dunno if it's capable of "passtrough" grabbing like saleae, that would be ideal...

I did install the software and it appears to function. To be honest, I've never actually used it, so that may take some effort. :).

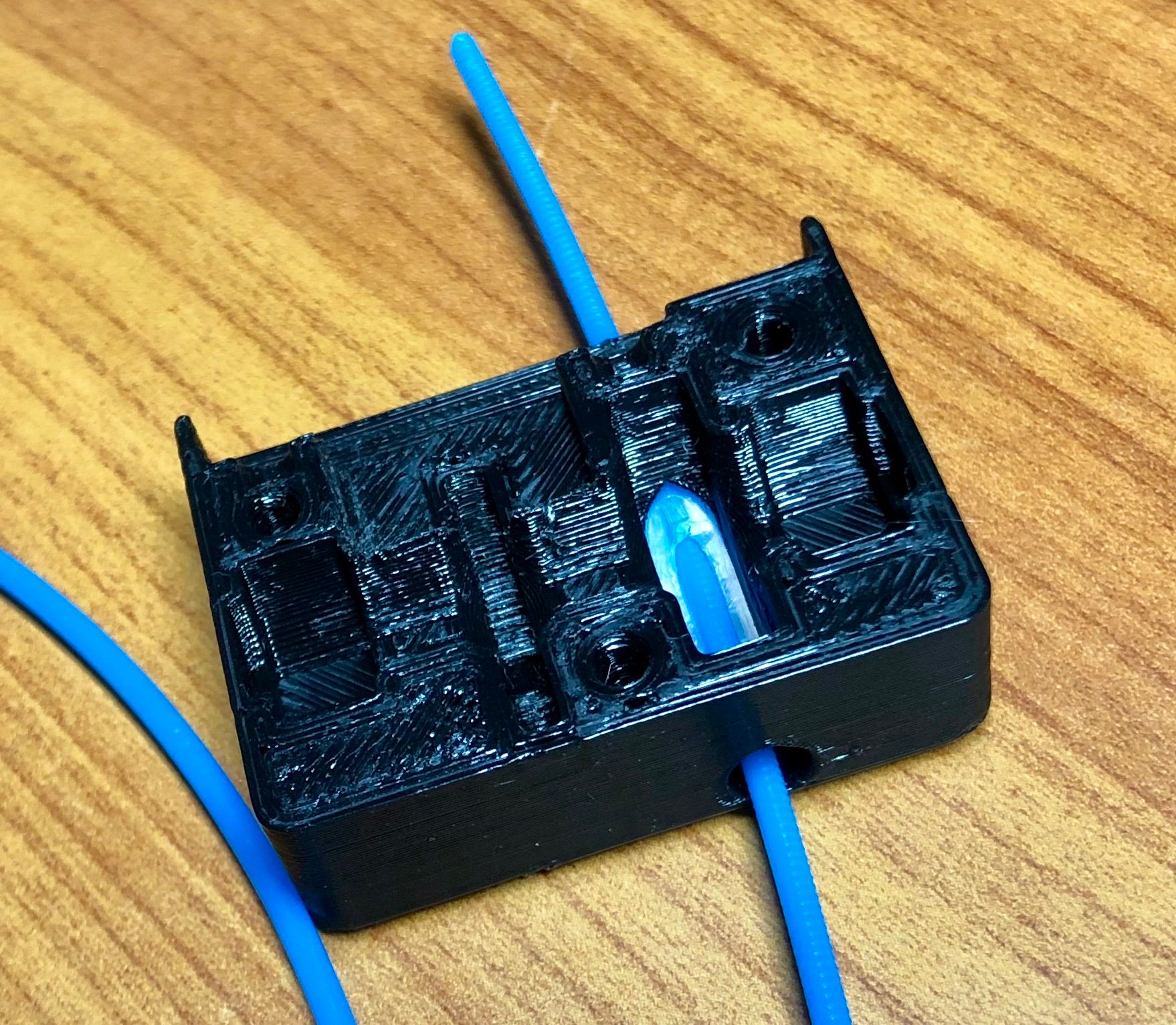

What is the interface material between the roller and the filament? And how is filament pressed to the roller?

It is a TPE roller pressing against the filament that is in a carved out channel of PTFE.

I've switched to a wheel with fewer, larger "spokes" as that was one recommendation from @fractalengineer

-

dunno how soft is that tpu, if you hold the encoder wheel witha hand and move the filament, how much force you need to apply to move it (as it will be slipping 'cause you are holding the encoder wheel) ?

a possible issue I see here is that many black plastic filaments are actually transparent to IR light and does not work reliably, or at all, as a light stop for the gap sensors. back in the day of darwin I had to tape the alu foil over the printed blade (and then painting it black with marker) going into the sensor for sensor to register it every time and at the same location. I haven't used printed wheels for more than a decade as when I make pcb's at home when I do films I have to pay for full width of the film (30 or 60cm) so I add to the film different encoder wheel designs I can later use in designes like this (high precision, low precision...).

I believe you can do the same here, just tape the piece of alu foil over the wheel and cut the holes trough alu matching holes on the plastic using a blade, black marker paint the alu foil after that and the transparency of the plastic issue should be gone

-

@arhi said in Inconsistent results with optical encoder wheel filament sensor:

dunno how soft is that tpu, if you hold the encoder wheel witha hand and move the filament, how much force you need to apply to move it (as it will be slipping 'cause you are holding the encoder wheel) ?

It is a semi-flex material, and printed mostly solid. I'll try that test this evening, but I'm expecting it is held pretty firmly.

a possible issue I see here is that many black plastic filaments are actually transparent to IR light and does not work reliably, or at all, as a light stop for the gap sensors. back in the day of darwin I had to tape the alu foil over the printed blade (and then painting it black with marker) going into the sensor for sensor to register it every time and at the same location. I haven't used printed wheels for more than a decade as when I make pcb's at home when I do films I have to pay for full width of the film (30 or 60cm) so I add to the film different encoder wheel designs I can later use in designes like this (high precision, low precision...).

I believe you can do the same here, just tape the piece of alu foil over the wheel and cut the holes trough alu matching holes on the plastic using a blade, black marker paint the alu foil after that and the transparency of the plastic issue should be gone

Interesting! The wheel I have in there now is actually a brown PLA plastic, but seeing the same results as with the black. I can try the foil method too -- or print in a different color/material. The black in the photograph is PETG, the current one is PLA+ .

Thanks,

John

-

@JohnOCFII I have not tested how each plastic is transparent to the IR but most are to some extent... alu tape is pretty simple and effective solution for that transparency... I'm not sure that's the issue you are having but at this point...

-

@arhi said in Inconsistent results with optical encoder wheel filament sensor:

If you can get that BitScope DSO to run I think that's a good way to move forward. Dunno if it's capable of "passtrough" grabbing like saleae, that would be ideal...

Passthrough would be ideal. Do you know how the Saleae Logic units do that? Do all the current models do that (might upgrade if so...). I'd prefer to use something that is still actively developed.

-

@JohnOCFII said in Inconsistent results with optical encoder wheel filament sensor:

@arhi said in Inconsistent results with optical encoder wheel filament sensor:

dunno how soft is that tpu, if you hold the encoder wheel witha hand and move the filament, how much force you need to apply to move it (as it will be slipping 'cause you are holding the encoder wheel) ?

It is a semi-flex material, and printed mostly solid. I'll try that test this evening, but I'm expecting it is held pretty firmly.

If I held the encoder wheel tightly, I could move the filament past the TPU wheel with less force than I expected. I had previously only tested by ensuring that when I moved filament through the unit, that the encoder wheel was moving properly.

I'll have to think about this.

a possible issue I see here is that many black plastic filaments are actually transparent to IR light and does not work reliably, or at all, as a light stop for the gap sensors. back in the day of darwin I had to tape the alu foil over the printed blade (and then painting it black with marker) going into the sensor for sensor to register it every time and at the same location. I haven't used printed wheels for more than a decade as when I make pcb's at home when I do films I have to pay for full width of the film (30 or 60cm) so I add to the film different encoder wheel designs I can later use in designes like this (high precision, low precision...).

Interesting!

I believe you can do the same here, just tape the piece of alu foil over the wheel and cut the holes trough alu matching holes on the plastic using a blade, black marker paint the alu foil after that and the transparency of the plastic issue should be gone

I'll give that a shot. I need to make sure that I can do something that doesn't make the encoder wheel much wider, as the channel is pretty thin.

Thanks again for the ideas.

John

-

@JohnOCFII saleae 8 uses the CY7C68013A mcu. That series of cypress mcu's have 8051 compatible core and a way to directly copy a port on to usb at 24MHz so to have 24 MHz pass trough 8 bit logic analyzer you just need that mcu + some input handling

I'm not sure if they configure trigger condition on the '51 or they do it in software

Their 16pin version comes with fpga and does not work the same but I don't have 16pin version so no clue how exactly it works nor what it supports. For more than pins I use obls or I use my trusty 400MHz agilent mxo

-

@JohnOCFII said in Inconsistent results with optical encoder wheel filament sensor:

If I held the encoder wheel tightly, I could move the filament past the TPU wheel with less force than I expected.

so if the dirt gets in, wheel get stuck, it will slip ?

I'll give that a shot. I need to make sure that I can do something that doesn't make the encoder wheel much wider, as the channel is pretty thin.

IMHO you can sand off 1mm from the side of the wheel where you will apply alu tape. IIRC alu tape is .25mm thick so that should do it.

-

@arhi said in Inconsistent results with optical encoder wheel filament sensor:

@JohnOCFII saleae 8 uses the CY7C68013A mcu. That series of cypress mcu's have 8051 compatible core and a way to directly copy a port on to usb at 24MHz so to have 24 MHz pass trough 8 bit logic analyzer you just need that mcu + some input handling

Do you need extra hardware, or is it just a matter of connecting one lead from the Saleae to the signal pin on the optical encoder (in this case) and a different lead to the appropriate signal pin on the Duet, and setting the software to "passthrough from lead x to lead y?

-

@arhi said in Inconsistent results with optical encoder wheel filament sensor:

@JohnOCFII said in Inconsistent results with optical encoder wheel filament sensor:

If I held the encoder wheel tightly, I could move the filament past the TPU wheel with less force than I expected.

so if the dirt gets in, wheel get stuck, it will slip ?

Yes, especially with the Bondtech extruder pulling as strongly as it does.

I'll give that a shot. I need to make sure that I can do something that doesn't make the encoder wheel much wider, as the channel is pretty thin.

IMHO you can sand off 1mm from the side of the wheel where you will apply alu tape. IIRC alu tape is .25mm thick so that should do it.

The encoder wheel is only 1mm thick...

I'm going to have to think about this...

Thanks for your ideas and input!

-

@JohnOCFII said in Inconsistent results with optical encoder wheel filament sensor:

The encoder wheel is only 1mm thick...

looks thicker on the picture

.. anyhow, if you have aluminium tape, you can stick it on one side, cut, then sand plastic side till it fits the groove properly... the alu tape is rather thin so it is easy to sand off that much from the plastic side.

.. anyhow, if you have aluminium tape, you can stick it on one side, cut, then sand plastic side till it fits the groove properly... the alu tape is rather thin so it is easy to sand off that much from the plastic side.Do you need extra hardware, or is it just a matter of connecting one lead from the Saleae to the signal pin on the optical encoder (in this case) and a different lead to the appropriate signal pin on the Duet, and setting the software to "passthrough from lead x to lead y?

the saleae has the "extra hardware" as the input circuitry (iirc there's octal bus transciever or something like that making it work ok with 3v3 and 5v signals) so what you would do is connect GND from saleae to GND on the duet and S1 from the saleae to the connlcd.encb set the sw to start scanning at some lower freq (no need to do 25MHz, 100Hz is more than enough I think, maybe 1kHz) and let it scan for couple of minits during printing and then you click stop and analyze the trace.

-

@arhi said in Inconsistent results with optical encoder wheel filament sensor:

@JohnOCFII said in Inconsistent results with optical encoder wheel filament sensor:

The encoder wheel is only 1mm thick...

looks thicker on the picture

.. anyhow, if you have aluminium tape, you can stick it on one side, cut, then sand plastic side till it fits the groove properly... the alu tape is rather thin so it is easy to sand off that much from the plastic side.

.. anyhow, if you have aluminium tape, you can stick it on one side, cut, then sand plastic side till it fits the groove properly... the alu tape is rather thin so it is easy to sand off that much from the plastic side.I can also sand out the slot too -- or maybe see if @fractalengineer will share the design files so I can widen out the slot.

Do you need extra hardware, or is it just a matter of connecting one lead from the Saleae to the signal pin on the optical encoder (in this case) and a different lead to the appropriate signal pin on the Duet, and setting the software to "passthrough from lead x to lead y?

the saleae has the "extra hardware" as the input circuitry (iirc there's octal bus transciever or something like that making it work ok with 3v3 and 5v signals) so what you would do is connect GND from saleae to GND on the duet and S1 from the saleae to the connlcd.encb set the sw to start scanning at some lower freq (no need to do 25MHz, 100Hz is more than enough I think, maybe 1kHz) and let it scan for couple of minits during printing and then you click stop and analyze the trace.

Cool. I might just have to upgrade. I see they have "Enthusiast Pricing" for the basic Logic 8.

-

well the saleae software is very very very good (better than most I tried, maybe the best) but hw prices are not very popular, logic8 is $400 while clone that features 90% identical hw is $7 (the clone is only missing a few $ worth parallel adc to have analog channel instead of 8 digital ones)... the logic16 is $1000 .. that's really high ... no it should have unlimited depth trough usb3 at 100mhz but ... for $1k ..

-

@arhi said in Inconsistent results with optical encoder wheel filament sensor:

well the saleae software is very very very good (better than most I tried, maybe the best) but hw prices are not very popular, logic8 is $400 while clone that features 90% identical hw is $7 (the clone is only missing a few $ worth parallel adc to have analog channel instead of 8 digital ones)... the logic16 is $1000 .. that's really high ... no it should have unlimited depth trough usb3 at 100mhz but ... for $1k ..

Looks like Enthusiasts can get the Logic 8 for half price:

https://blog.saleae.com/saleae-discounts/

I value good software, and will pay for it.

-

@JohnOCFII $200 is totally acceptable ... I don't remember how much I paid for mine (I think it was 300eur but not sure) but I needed a throughput then so much I was willing to pay even more as I had a choice - a ready-made device with working SW, or making one from arm32 with software from scratch, 300eur was waaaaaaaaaaaaaay cheaper than me making it from scratch and OBLS while superbly good could not get the job done as I needed depth (and even chained 3 obls's I have could not cut it). few other logic analyzers use almost identic schematic as logic8 ... anyhow getting too much off-topic

my idea of using logic analyzer here, low scan frequency needed only, 1 channel, so could probbly made using arduino board, is to grab signals from a probe during "constant extrusion time" ... so if you know that next "minute" the extrusion will be "constant"

- reset the sensor data on the duet (by issuing

M591 D0 P7 C"connlcd.encb" S0 R50:1500 L1.2 E5 A1or what is your filament sensor config line) - start recording

- wait a minute

- stop recording and read filament data

now compare min/max with what you read from the logic analyzer.

analyze jitter in the impulses you read from the probe - you should have pulses evenly spaced. if you see pulses "too close to one another" or pulses missing those are either errors from the sensor or errors in g-code (extrusion is not that constant as you would expect - this will happen often with shitty slicers).One other thing that's possible requires some disassembling or using spare parts. That's what I'd do

- make a logic analyzer out of some arduino board or similar (no need for MHz speed so no need for a few hundred bucks worth of LA for this purpose, by all means, if you need a good LA saleae is great, dl the sw to test it works without LA in demo mode, you will love it

)

) - feed filament trough your sensor

- feed filament into extruder (you said you use bondtech)

- remove hotend, so filament is now just going out of the extruder, no melting...

- make your own g-code to something like this

M302 P1 ; Allow cold extrusion G92X0Y0Z0 ; duet now assume we are homed M82 ; extruder absolute position G92E0 ; reset extruder to 0 M591 D0 P7 C"connlcd.encb" S0 R50:1500 L1.2 E5 A1 ; config filament sensor G1 E1000 F120 ; extrude 1000mm at 2mm/sec, so will be extruding around 8 minutes M591 ; query filament sensor- mark the filament with a marker at exit point of the extruder

- execute this code as gcode file (you need to start print for filament to actually work)

- while code is running log the impulses with logic analyzer

- when code finish, mark the filament at exit point of the extruder

now you

- analyze logic analyzer output

- look at the readout of the m591

- measure the exact length of the filament extruder with a meter (you have two marks on it) and compare to M591 output (over xxx mm value)

- reset the sensor data on the duet (by issuing