how to setup duet 3 extension 1LC driver ?

-

@Veti

okay, I check the wiring and now the motor is spining.

But, when it stop spining it make a strage noise like electrical noise or like he is forcing, it is normal ? -

send M569 P121.0 in the console.

if it is in spreadcycle that is normal.

see this

https://duet3d.dozuki.com/Wiki/Reducing_Stand-Still_Noise -

It return this. I now how to interprete it ?

M569 P122.0

Driver 122.0 runs forwards, active low enable, mode spreadCycle, ccr 0x00053, toff 3, tblank 0, hstart/hend/hdec 5/0/0, pos 612 -

-

@Veti I don't now if it help but I use this motor :

https://www.bondtech.se/wp-content/uploads/2019/02/13003-Nema17-25mm.pdfAnd I have an other question, did the E-step is the step per mm ?

-

@Pseud3mys said in how to setup duet 3 extension 1LC driver ?:

I don't now if it help but I use this motor :

no it does not help. you need to follow the guide and try it for yourself which parameter reduces the standstill noise.

did the E-step is the step per mm ?

i am not sure what you are asking.

-

@Veti Thanks, now fixed in configtool version 3.1.10.

-

@Veti yes I change the mode It is okay now thank you.

-

@Veti I have always some issues..

Some time the button here don't stop spinning, even after than the motor stop spining. -

try a newer dwc

-

Have you defined the heater on the toolboard using the M950 command in your config.g?

For example:

M950 H1 C"121.out0" T1And you need to map the thermistor using the M308 command.

M308 S1 P"121.temp0" Y"thermistor" T100000 B4725 C7. 06e-8 A"Hot End" -

@Veti said in how to setup duet 3 extension 1LC driver ?:

try a newer dwc

It is already the lastest version, beta4.1 for the reprap firmawre and beta4 for the web interface.

-

@CaLviNx yes, this is my config for it:

; configure sensor 1 as thermistor on pin 121.temp0 M308 S1 P"121.temp0" Y"thermistor" T500000 B3600 C1.196220e-7 H-12 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 -

Try this instead

M569 P121.0 S1 ; Driver 121.0 is connected to the extruder motor output (Driver 0) on the toolboard LC1 & goes forwards -

@CaLviNx said in how to setup duet 3 extension 1LC driver ?:

M569 P121.0 S1 ; Driver 121.0 is connected to the extruder motor output (Driver 0) on the toolboard LC1 & goes forwards

ah yes for the driver I aldready put some thing similary:

; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P121.0 S1 D3 V2000 ; physical drive 1.0 goes forwards M569 P122.0 S1 D3 V2000 ; physical drive 2.0 goes forwards M584 X0.0 Y0.1 Z0.2 E121.0:122.0 ; set drive mapping M350 X256 Y256 Z256 E64:64 I0 ; configure microstepping without interpolation M92 X80.00 Y80.00 Z400.00 E415.00:415.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min) M203 X31800.00 Y31800.00 Z31800.00 E1200.00:1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800:800 ; set motor currents (mA) M84 S0 ; Disable motor idle current reduction -

Please post your complete config.g file.

-

@dc42

Here my full config.g file:; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.1.9 on Wed Dec 02 2020 17:31:45 GMT+0100 (heure normale d’Europe centrale) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"MultiTool Cartesian" ; set printer name ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P121.0 S1 D3 V2000 ; physical drive 1.0 goes forwards M569 P122.0 S1 D3 V2000 ; physical drive 2.0 goes forwards M584 X0.0 Y0.1 Z0.2 E121.0:122.0 ; set drive mapping M350 X256 Y256 Z256 E64:64 I0 ; configure microstepping without interpolation M92 X80.00 Y80.00 Z400.00 E415.00:415.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min) M203 X31800.00 Y31800.00 Z31800.00 E1200.00:1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800:800 ; set motor currents (mA) M84 S0 ; Disable motor idle current reduction ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X1000 Y1000 Z800 S0 ; set axis maxima ; Endstops ; WARNING: No endstops configured ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X20:980 Y20:980 S80 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C ; configure sensor 1 as thermistor on pin 121.temp0 M308 S1 P"121.temp0" Y"thermistor" T500000 B3600 C1.196220e-7 H-12 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; configure sensor 2 as thermistor on pin 122.temp0 M308 S2 P"122.temp0" Y"thermistor" T500000 B3600 C1.196220e-7 H-10 L-12 M950 H2 C"122.out0" T2 ; create nozzle heater output on 122.out0 and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S280 ; set temperature limit for heater 2 to 280C ; Fans M950 F0 C"121.out2" Q500 ; create fan 0 on pin 121.out2 and set its frequency M106 P0 S0 H1 T160 ; set fan 0 value. Thermostatic control is turned on M950 F1 C"122.out2" Q500 ; create fan 1 on pin 122.out2 and set its frequency M106 P1 S0 H2 T160 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 S"Extrudeur 0" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 S"Extrudeur 1" D1 H2 F1 ; define tool 1 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C M563 P2 S"Spindle" F-1 ; define tool 2 G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory -

@Pseud3mys said in how to setup duet 3 extension 1LC driver ?:

M350 X256 Y256 Z256 E64:64 I0 ; configure microstepping without interpolation

this will overload your cpu. go with x16 and interpolation for now.

M906 X800 Y800 Z800 E800:800 ; set motor currents (mA)

you need to set the correct current for the motors. go with 75% of the rated current.

-

The X, Y, Z motors are, for now not connected. I am just tring to setup the extruder/hotend. So I don't use the XYZ driver.

-

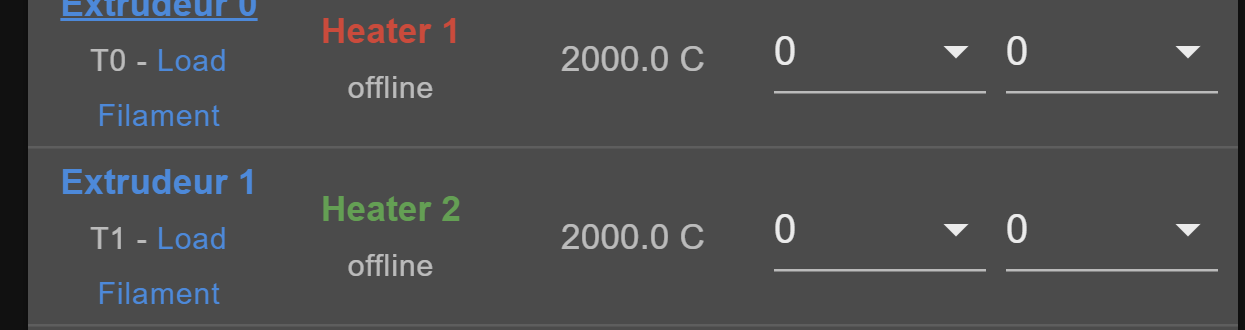

just to prevent, after a restart when we change the config.g file (when we click yes on the pupop "reset board ?") this happen:

I am in beta4.1 and I think this didn't happen in beta4 (whoever I am not sure).

I just need an emergency stop to fixe it.