IDEX printer plays TicTacToe (soon)

-

To celebrate the new level of 3D printing named conditionals and variables I thought it would be funny to rebuild my old Prusa i3 to an IDEX with infinite Y-axis.

A macro would then apply Tic Tac Toe rules to the two feltpen-tools which actually write X and O to a foil on the bed.

The infinite Y-axis would then scroll the foil around and thereby wipe off the nonpermanent ink.With this thread I want to encourage other users to think out off the box and come up with their crazy ideas to celebrate the amazing Duet team and their breakthrough Firmware.

-

Sounds fun! You can use the random(nn) function to randomise the moves either partially or completely.

-

@dc42

Random for the first move is OK, but then I hope to create a bit of AI in the macro. -

The first step was easy.

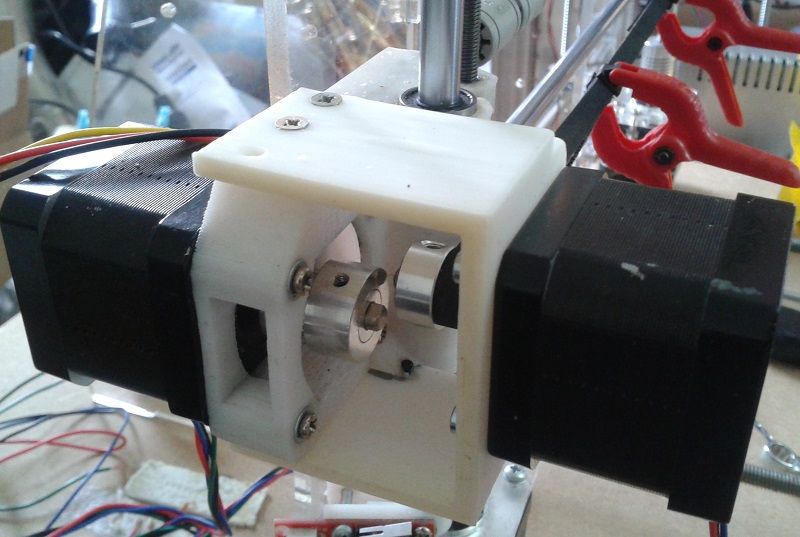

I made a bracket that fits onto the existing X-motor.

Also extended the idler-shaft. Not my best design, but it's only a fun project moving feltpens around.

-

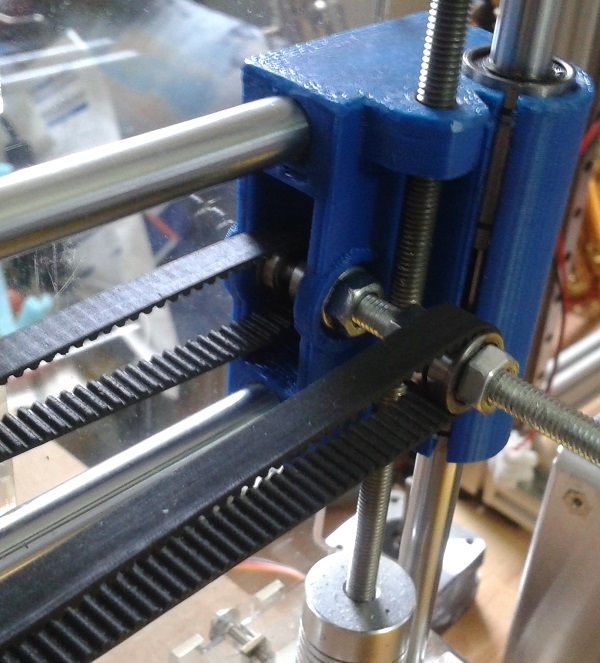

Today I made the toolholders, which isn't perfect yet. I thought, I could design a universal tool, but the belts are rubbing on the unused beltclamp. Have to saw them off or reprint two versions. No biggy! Tomorrow is config-time. Never had a IDEX before, it's gonna be a headache to find all relevant infos (and understand them

)

)PS: This might be a nice diode-laser toolholder too

-

Ok, configuring the DuetMaestro as "PruDEX" wasn't to hard. It's updated to RRF3.3b2, also the DWC interface.

And here it get's a bit ugly.

@chrishamm

How can I configure DWC not to show temp-graphs and all the stuff I don't have?

I've read there are versions for CNC machines (maybe laser too?), but couldn't figure out how to set these?

Do I have to put my machine in Laser-mode?THX

-

@o_lampe said in IDEX printer plays TicTacToe (soon):

I've read there are versions for CNC machines (maybe laser too?), but couldn't figure out how to set these?

You have to use the experimental CNC version of DWC, and put the machine into CNC mode using M453.

-

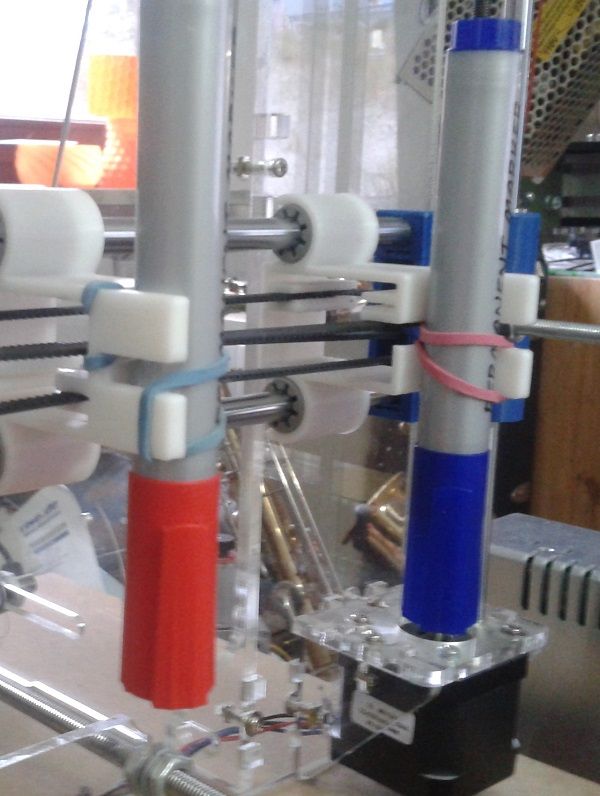

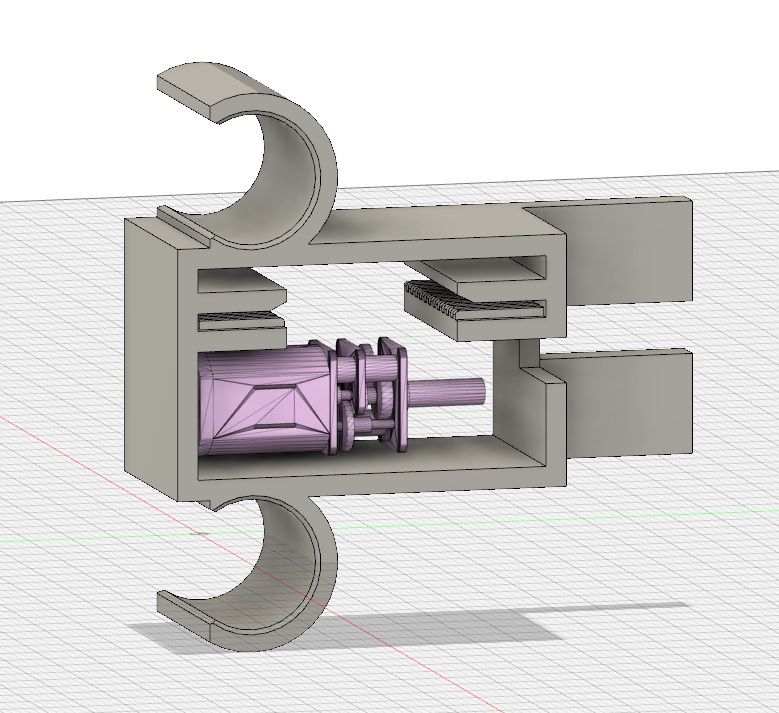

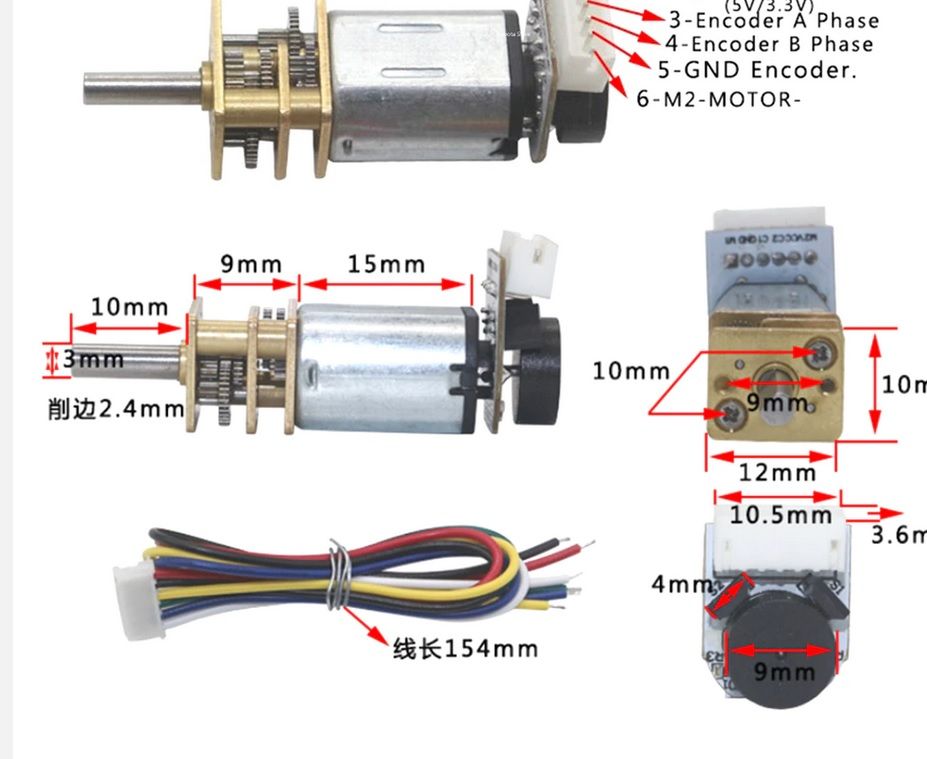

BTW: I figured out a method to have many tools on the X-axis.

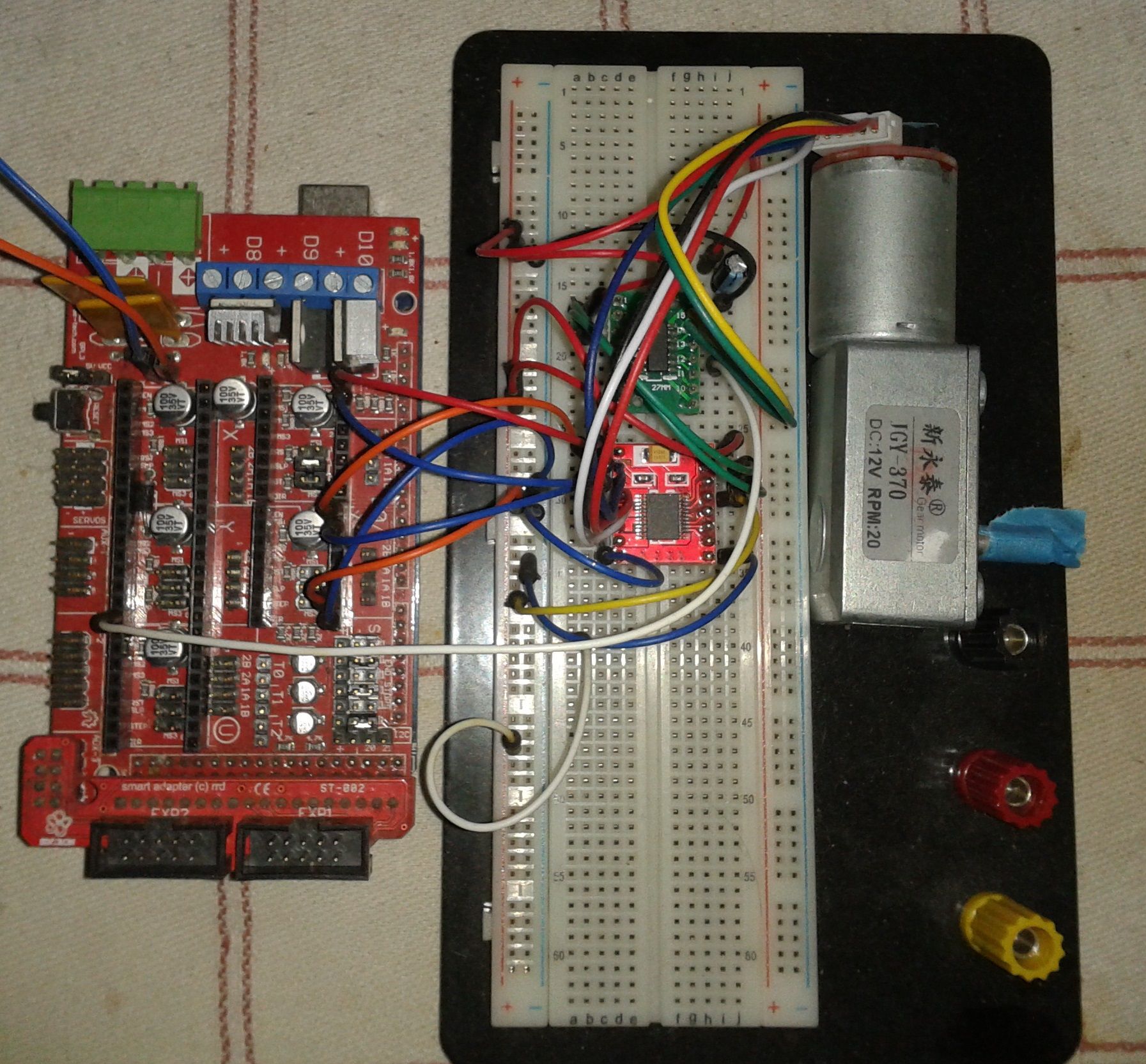

Two years ago I developed software and a circuit that allowed me to control geared dc motors with encoder like steppers.

Now there are big motors suitable for heavy lifting (eg. rotary delta), but also tiny "N20" motors with metal gearboxes. They would fit perfectly in the toolholder I designed for this project.

The tools would all use a single belt, like "shapeoko CNC" does. Kind off Rack and Pinion.

Controling them would either require dir,step and enable pins for each tool, but with a "shift register" for the enable signal, I could control them all_at_once. (shared dir and step signals) Pretty handy for toolchanges, where lot's of tools have to travel from left to right and vice versa. (worst case is selecting the last tool and park all others)Here is the test-bench with the big motor, which still needs to become a real PCB...

(hint: is there PCB designer with some spare time? Contact me )

)

Question is, what would you do with tons of tools?

The feltpen- carousel comes to my mind. A single extruder and a few different colored pens for texture mapping. -

I'm glad I started learning IDEX printing on a fun project where it doesn't matter when things go wrong.

Running a testfile I paused the print and changed tool. The tfree macro worked as expected, but after hitting resume both axes were moving for a moment. I guess the print queue wasn't empty?

OTOH, when I send T0 or T1 without pausing, everything works. I know there is a M400 wait until printbuffer clear, but where do I put it?@dc42

I used the configurator tool to generate my config.g. When I defined the tools without fan the configurator adds a "F-1" to M563.

But RRF3.3b2 doesn't accept that and throws an error, when running M98 "Pconfig.g".

Something like "expecting a numeric expression after 'F' param"Maybe I' m the first noticing that, otherwise ignore it...

; Tools M563 P0 S"X-Axis" F-1 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 S"U-Axis" F-1 ; define tool 1 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C M563 P2 S"XU-Copy" F-1 ; define tool 2 G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C