How do I enable the hot end heater

-

@kb58 said in How do I enable the hot end heater:

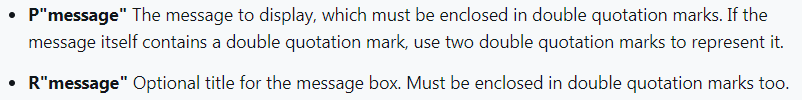

Don't see how, given that:

So R is just an option title.

About the G30 s-1, it's just for checking on what the printer thinks the probe to bed offset is. Want to make sure it's not drifting.

Hmm... You are correct. I thought I read where it was required but it works without it.

OK - add some M291 commands with an S2 parameter and a meaningful message to print_begin.g so you can determine what is being executed and what is not.

For example before the G32 you could have:

M291 P"About to execute G32" S2

Then before the T0 you could have:

M291 P"About to execute T0" S2

Frederick

-

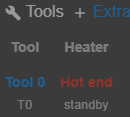

@fcwilt So to sort of bring this to a close, I found out through dumb luck that I have to click on the filament type in this window.

With that solved, another has to pop up, and it did. Right when it starts to do its bed leveling, it pops up a warning about "Tool not selected", but it is, and if the warning is ignored, everything works as it should anyway. While a nuisance warning, it would be nice to know why it's happening and correct it.

Here's the relevant bit:

; select tool and configure based on filament selected T0 ; select tool 0 so extruder commands work M703 ; loads selected filament configuration (bed/extruder temps, extrusion ; multiplier, etc). See config.g in filament folder. G32 ; home and level bed, then move to bed center and set Z datumI don't get it; T0 is selected right before setting up the filament, and the tool-not-selected warning appears right when the G32 command starts. Huh.

-

Did you remove these "sanity" checks I had in print_begin.g:

; check for selected filament if move.extruders[0].filament = "" M291 R"No Filament Selected" P"Cannot Continue" S2 T0 abort ; check bed heater active temp setting if heat.heaters[0].active = 0 M291 R"Bed Heater Active Temp = 0" P"Cannot Continue" S2 T0 abort ; check extruder heater active temp setting if heat.heaters[1].active = 0 M291 R"Extruder Heater Active Temp = 0" P"Cannot Continue" S2 T0 abortYou will notice the first one checks if a filament has been selected.

Frederick

-

@fcwilt Yes... and no.

Yes they were removed, with the thinking that once I had it basically working, I'd add it back in. During figuring this out I looked back through your code and realized those are pretty good checks, so added in that chunk. See, it takes me a while to wrap my head around new code

-

@kb58 said in How do I enable the hot end heater:

With that solved, another has to pop up, and it did. Right when it starts to do its bed leveling, it pops up a warning about "Tool not selected", but it is, and if the warning is ignored, everything works as it should anyway. While a nuisance warning, it would be nice to know why it's happening and correct it.

I've got a printer that uses G32 in that location and I am not getting any warning.

You have G28 in your bed.g file.

Does your home all code have anything that would de-select all tools?

Frederick

-

@fcwilt Good point, that would do it, but no. I need to snoop around and see if there's any deselection of tools anywhere. There should not be because this is, and probably always will be, a single tool machine:

; homeall.g ; called to home all axes ; G91 ; relative positioning G1 H2 Z5 F10000 ; lift Z relative to current position G1 H1 X-355 Y-355 F3000 ; move quickly to X or Y endstop and stop (first pass) G1 H1 X-355 ; coarse home X G1 H1 Y-355 ; coarse home Y G1 X5 Y5 F600 ; go back a few mm G1 H1 X-10 ; move slowly to X axis endstop once more (second pass) G1 H1 Y-10 ; then move slowly to Y axis endstop G1 H1 Z-355 F360 ; move Z down, stopping at the endstop G90 ; absolute positioning G92 Z4.5 ; set Z position to axis minimum (may need to adjust) -

@kb58 Searched all files and there is no "T-1" anywhere. I'm wondering if it takes time to take effect, but that seems highly unlikely given what it's doing. It's not like it's physically moving anything, or doing nasty math.

-

@kb58 said in How do I enable the hot end heater:

@fcwilt Yes... and no.

Yes they were removed, with the thinking that once I had it basically working, I'd add it back in. During figuring this out I looked back through your code and realized those are pretty good checks, so added in that chunk. See, it takes me a while to wrap my head around new code

I don't add code just for the "fun" of adding code - I try to protect my 71 year old mind from doing stupid things.

Frederick

-

@fcwilt I may add in several print statements to see what the tool state is, but obviously that's not a fix, but would still be curious where or how it's not happening.

-

@kb58 said in How do I enable the hot end heater:

@fcwilt I may add in several print statements to see what the tool state is, but obviously that's not a fix, but would still be curious where or how it's not happening.

I wish the DWC had a means to search all files which would make finding errant code bits easier.

Yes I can download everything into my standalone editor which will do such a search but I tend to avoid doing it.

Frederick