Duet Mini 5+ and Co2 50W laser Guidance

-

Hi Guys,

I need a hand before I end up blowing something up please.

I have a duet 3 mini 5+ and I want to hook it up to my K40 laser which has a 50W tube and PSU.

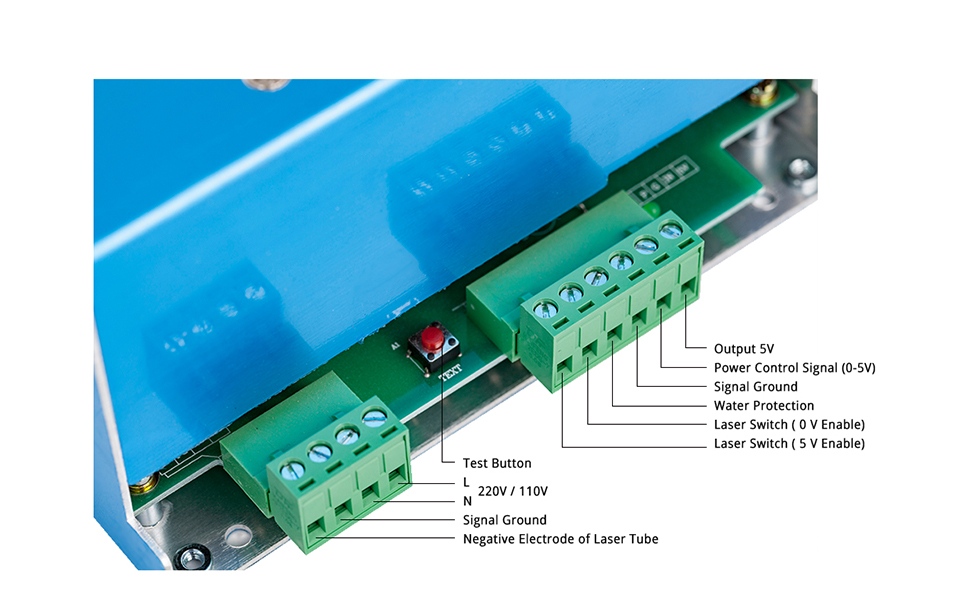

Above Is the PSU it has and I'm lost. I have tried hooking up out6_buff in every imaginable way and I just can't get it to work. This is the first time I'm playing with these so pretty much clueless.

If I hook up a potentiometer and the test fire pin it works from the test fire. But I have no idea how to replicate this with the 3 pins from the mini.

If I hook up Out6_buff to TTL it fires constantly with the GND and 5V_Ext on the gnd and 5V pins respectively.

If I put the 5V_EXT on TTH and GND on TTL and the out6_buff on IN (Wiper pin second from the right) i get lootoo. (Nothing)

Do I have to add in another pin for the firing? I'm seriously confused about how this should work

I have tried hundreds of different way and at a loss here. I have read everything I can find in the guides, but for the life of me I can't figure out how this should fit together. My Water protection pin is bridged, and if I run 5V out over to TTH it fires.

Here is my config as it stands currently. I have chopped and changed and tried so many different pin names and frequencies it's a bit of a mess currently.

I have a delta running a duet 2, built corexy's with duet 3's. this is 3 pins and I'm stumped.

; Configuration file for Duet 3 Mini 5+ (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.2 on Thu Sep 09 2021 14:52:42 GMT+0200 (South Africa Standard Time); General preferences

G90 ; send absolute coordinates...

M550 P"Laser" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

M452 ; enable laser mode; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M584 X0.0 Y0.1 ; set drive mapping

M350 X16 Y16 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 ; set steps per mm

M566 X900.00 Y900.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 ; set accelerations (mm/s^2)

M906 X400 Y600 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 S1 ; set axis minima

M208 X300 Y300 S0 ; set axis maxima; Endstops

M574 X1 S1 P"!io1.in" ; configure active-high endstop for low end on X via pin !io1.in

M574 Y1 S1 P"!io2.in" ; configure active-high endstop for low end on Y via pin !io2.in; Enable Laser Mode

M452 C"out6_buff" R255 Q500 ; Enable Laser mode, on out6 laser pin, with max intensity being 255, and a PWM frequency of 200; Z-Probe

M558 P0 H0 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M557 X15:215 Y15:195 S20 ; define mesh grid; Fans

M950 F0 C"out5" Q500 ; create fan 0 on pin out5 and set its frequency, air assist 220v pump on relay

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off; Custom settings are not defined

-

@shauncro said in Duet Mini 5+ and Co2 50W laser Guidance:

Do I have to add in another pin for the firing?

You should connect the power control signal with out6_buff and signal gnd with a gnd pin on the Duet. Don't connect the output 5V to anything.

Then add another GPIO pin and connect it to one of the Laser switch pins. I'd recommend using the 5V enable pin and configure the Duet output accordlingly.This enable pin should be protected by an external safety switch (keylock) in series to avoid misfiring on boot up or reset

-

@o_lampe thank you! I'll give it a go when we get power back later. This has been frustrating me for 3 days now.

-

So I'm still battling with this.

I realised I didn't have a tool defined, so did so, and it kinda got me somewhere, but didn't.

But then when running through the config tool, I notice there is a pin allocation for vfd that isn't in any of the documentation.

I have been playing with this and either the laser turns on to full throttle, or it doesn't turn on at all. Which in a way is progress.

-

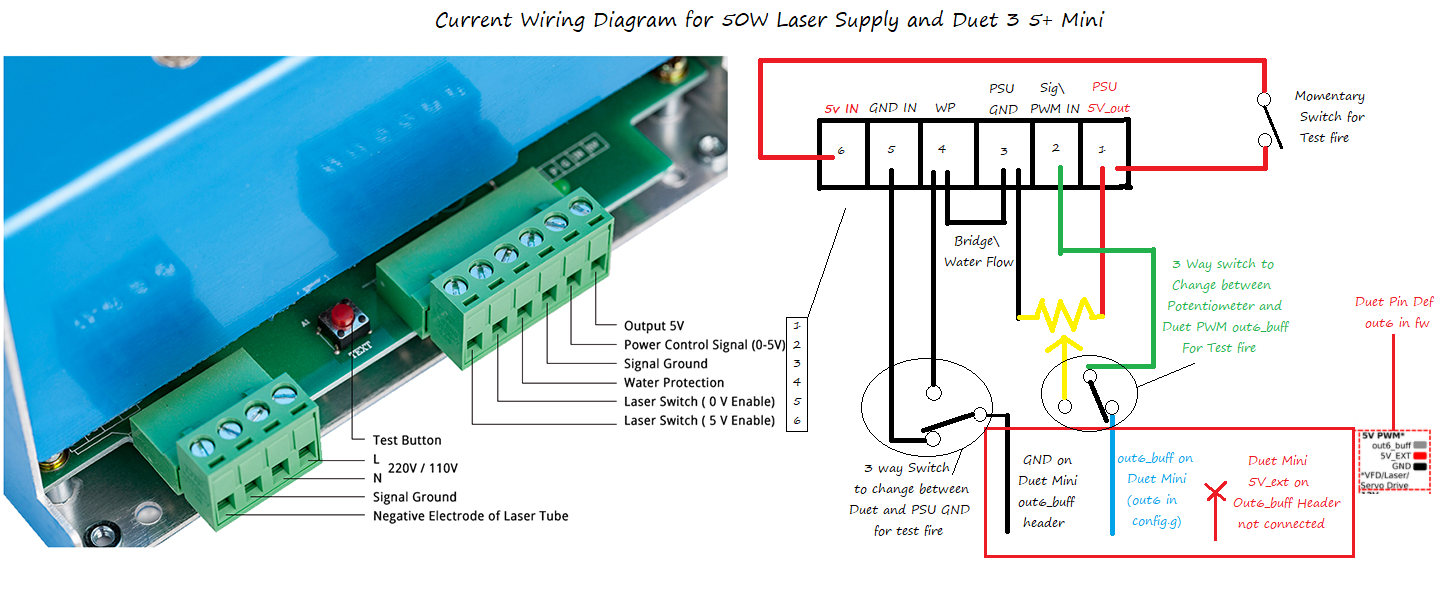

So I figured this out a few days ago and in case anyone else is trying to do the same thing, this is how I accomplished it. I'm not saying it's right, but it works.

My biggest confusion was more to do with the firmware. And the lack of anything depicting the tool once configured. I don't have a temp sensor on my K40 it's an older version, and from what I can see the guy I bought it from didn't know much either. But regarding the interface, There is pretty much nothing you can do (from what I have found) to depict this, the PWM setting is controlled in app by the G1 Snn Parameters, there is no set strength setting in the interface for testing purposes, so it's confusing as all hell. But slice the file, and upload and you'll soon find out whether or not you have it setup correctly. I'm using openbuildsCAM to do my slicing as it allows me to set the max value for the Laser (I have mine set to 204 which is 80% of 255 the value that we stipulate to be the max power out put in the firmware). It also allows me to generate multiple processes within a file so that I can Engrave and cut without losing my reference point on the work piece by having to re-home for another task.

Below is my config, use at your own risk, I accept no responsibility. All I'm saying is this works for me and this is more for my sanity and should I ever have to revisit this to remember what the hell it was that I did to just get the damn thing to work!!!!

I'm still trying to figure out how to remove the Z axis, but I have added into my start up after the G28 X0 Y0 that it runs M564 H0 to disable the need to have the axis homed. I do this only after the X and Y have homed so that I have my work area reference point.

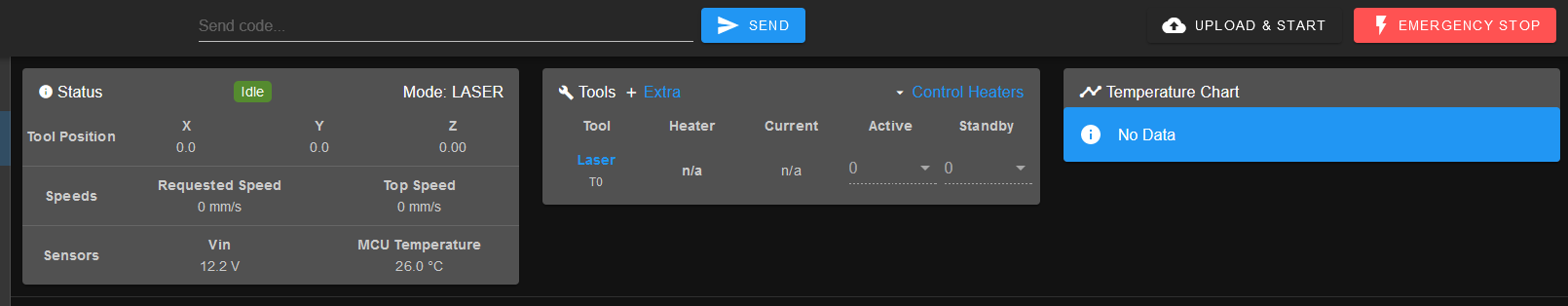

This is all I get on the interface, I honestly have no idea if this is what it's meant to look like or not, as I can't seem to find anything to say "Hey, if it doesn't look like this you f-d up buddy", and if you do use my config, then it's what you will have too. I have a Fan0 as well which is out5 pin and that connects to a 220V SSD and turns my Air Assist on or off. Currently my waterpump turns on as the machine turns on, but I need to get a water flow meter. My extraction unit is separate at this point, but will be moved to a relay and controlled the same way as the air assist. And I need to wire up a thermistor to monitor the water temp. But this is working. I'll update incase anyone needs it. I know I will most likely need to know what I did later on.

On the wiring diagram (Please just marvel at my awesome MS Paint Skills, this is a joke) I wired up the existing Potentiometer and 2 x 3 way switches so I could still use the test fire for calibration as I could find no way to fire the laser from the interface to do this. And not wanting to blow the board, I installed these to have them isolated when doing any testing and calibration. I'm not sure if it's necessary, but it makes me feel warm and fuzzy.

Laser ```Current Config.g ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Laser" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S0 ; physical drive 0.0 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M584 X0.0 Y0.1 ; set drive mapping M350 X16 Y16 I1 ; configure microstepping with interpolation M92 X160.00 Y160.00 ; set steps per mm M566 X900.00 Y900.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 ; set accelerations (mm/s^2) M906 X400 Y400 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X300 Y300 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io1.in" ; configure active-high endstop for low end on X via pin !io1.in M574 Y1 S1 P"!io2.in" ; configure active-high endstop for low end on Y via pin !io2.in ; Z-Probe ;M558 P0 H0 F0 T6000 ; disable Z probe but set dive height, probe speed and travel speed ;M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters ;M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 ;M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 ;M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit ;M140 H0 ; map heated bed to heater 0 ;M143 H0 S120 ; set temperature limit for heater 0 to 120C ;M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1 ;M950 P0 C"out6" M452 C"out6" R255 Q500 ;M50 P0"vfd" ; create nozzle heater output on out1 and map it to sensor 1 ;M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ;M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"out5" Q500 ; create fan 0 on pin out5 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off ;M950 F1 C"out6" Q500 ; create fan 1 on pin out6 and set its frequency ;M106 P1 S0 H-1 ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 S"Laser" ; define tool 0 G10 P0 X0 Y0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C -

@shauncro said in Duet Mini 5+ and Co2 50W laser Guidance:

I'm still trying to figure out how to remove the Z axis,

You can try the P-parameter in M584 to make Z axis invisible, but I haven't tested whether DWC allows you to hide the most important axis? (important in 3D printing and CNC)

Q: is the three way switch a double pole/double throw type? It would activate the potmeter and the test-pin at the same time.

But if you have two separate switches, you might loose PWM control by Duet, if the GND switch is set wrong.BTW: I'm still missing emergency-switch and keylock....

-

@o_lampe So, yes, no emergency switch or key lock, but it's only really me in my workshop, and the mains switch is mounted in front on a big red rocker switch. But, I'll grab a proper one next week after pay day. (Bought a laser, a bit broke now

right now my bed is a braai grid, and that's how it came. O.o )

right now my bed is a braai grid, and that's how it came. O.o )On the switches, they essentially toggle switches. With 3 position activating the pin assigned to that pin. When flipped left the Pwm for the board is active, middle off, right the potentiometer, and I have them all next to one another so it's a sequence, turn off duet gnd, turn on psu gnd, second toggle turn off duet out6 turn on potentiometer, and I'm missing a switch there, there is a switch between the momentary and the psu 5v_out which enables the 5v and allows the momentary to fire the test. But, my wiring is wrong in any case, I need to move the momentary switch to the negative opposed to the positive in,. Sitting on positive it fires at full power. So I need to disconnect it and move the momentary to the negative. And disconnect the + in completely as it isn't needed.

I work through a sequence, Turn off, switch over, turn back on and align mirrors. Turn off, and switch back. It's arduous, but it works till I can figure out something better or we get a test fire command. And since I'm the only one that's ever in my workshop, I just need to make sure complacency doesn't kick in. Or I resolve it before it does. The above is definitely not ideal, and I know this. But I'm a network tech not an electrical engineer, and it took me 5 days to figure out what and how it's all meant to go together to actually work, now that I understand it a bit better, I can work on improvements. But no where could I find a diagram of how it should all piece together and what the config should look like and what the interface should even look like at the end of it all. For instance, the interface doesn't even let you know whether the tool is active or not, like you have in fdm mode, there is a T0 and that is it, you click on it and it un-selects it, which by the way is active, and selecting it so that it's highlighted is inactive. Nothing else to give you any idea whether or not you successfully configured it, and what power level you are currently at or a test fire. So for someone that has never worked with a laser before, and wants a bit of info on what they should expect to see, that is pretty much it, at least they won't spend 5 days trying to figure out that there is actually no information they will be presented with, because there is pretty much nothing that tells us what we should expect to see on a successfully configured machine in any of the guides or even in the forums. There are a few things mentioned here and there, and you kinda have to fumble your way through risking a hell of a lot more than what the above diagram very basically explains. And I live in the ass end of Africa. The people around here mostly think a duet is witch craft, and I'm one of the only people on any of the groups I'm a part of that runs them, so now, I asked above, got one reply, which I kinda understood, but am pretty sure doesn't have much to do with my board, and more aimed at the duet 2, so muddled my way through so others wouldn't have to, at least now they can see plug this here and make sure something is disconnected or bad juju could come down from above and remove magic smoke or far worse. But this is also a work in progress. I've already added in a door switch that cuts the power off from the firing pin so that if opened, you don't become a local red shirt.