Nozzle temp continues to rise

-

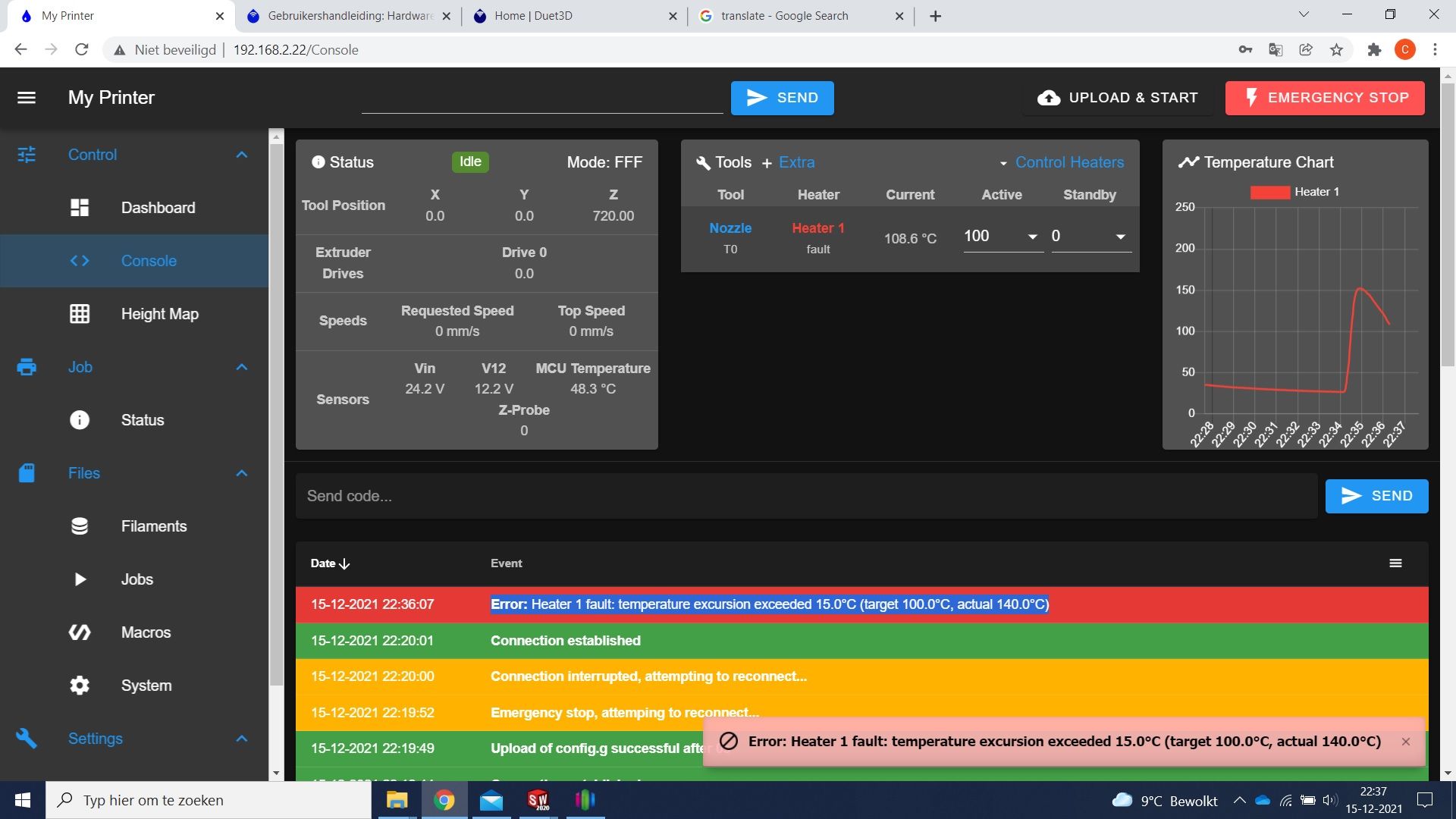

Little by little I get my delta configured. However, I can't get any further due to a problem with heater/pt1000 temp settings. As soon as I start a print or give a command to heat the nozzle, the temp continues to rise. The temperature rises very quickly and doesn't stop until "Error: Heater 1 fault: temperature excursion exceeded 15.0°C (target 100.0°C, actual 140.0°C)" kicks in. I've been looking for a solution for several days but haven't found anything yet.

Kind regards,

Coen

; Configuration file for Duet 3 (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.10 on Sun Dec 12 2021 23:02:28 GMT+0100 (Midden-Europese standaardtijd); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Printer" ; set printer name

M665 R267 L525 B225 H720 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them; Network

M551 P"0" ; set password

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0.0 S0 ; physical drive 0.0 goes backwards

M569 P0.1 S0 ; physical drive 0.1 goes backwards

M569 P0.2 S0 ; physical drive 0.2 goes backwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M584 X0.0 Y0.1 Z0.2 E0.3 ; set drive mapping

M350 X128 Y128 Z128 E64 I0 ; configure microstepping without interpolation

M92 X150.00 Y150.00 Z150.00 E80.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2)

M906 X2000 Y2000 Z2000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 Z0 S1 ; set minimum Z; Endstops

M574 X1 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io1.in

M574 Y1 S1 P"io2.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io2.in

M574 Z1 S1 P"io3.in" ; configure switch-type (e.g. microswitch) endstop for low end on Z via pin io3.in; Z-Probe

M558 P5 R0.4 C"io4.in+io4.out" H5 F1200 T6000 ; set Z probe type to effector and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 R85 S20 ; define mesh grid; Heaters

M308 S0 P"temp1" Y"pt1000" ; configure sensor 0 as PT1000 on pin temp1

M950 H1 C"out1" T0 ; create nozzle heater output on out1 and map it to sensor 0

M307 H1 D1 S1.00 B0 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S250 ; set temperature limit for heater 0 to 250C; Fans

M950 F0 C"out5" Q500 ; create fan 0 on pin out5 and set its frequency

M106 P0 S1 H0 T45 ; set fan 0 value. Thermostatic control is turned on

M950 F1 C"out4" Q500 ; create fan 1 on pin out4 and set its frequency

M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off; Tools

M563 P0 S"Nozzle" H1 F0:1 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings

M575 P1 B57600 S1 -

-

@fcwilt Great! Temp is stable now. Thank you so much for your help.

-

@coen_l said in Nozzle temp continues to rise:

@fcwilt Great! Temp is stable now. Thank you so much for your help.

Glad I was able to help.

Frederick