3.4rc1 early feedback

-

Some quick thoughts from just looking at the installation...

a) I had a devil of a time figuring out the address of the unstable server. Yes, I finally found it in the "Getting Started with Duet 3" page but ... it would be great if there were a simple 4-line script (all it takes) or a link on the actual github releases page.

b) Thank you so much for integrating the CNC gui. Woohoo.

c) On the CNC Gui I have some observations. Gui's are always somewhat subjective but there are objective concerns.

i) There's a lot of white space on things like the speed readout. For buttons white space is great but for displayed data it just makes it harder to fit in a small display.

ii) I personally would rather not have, at all, the following buttons->

. Home All : never used

. Compensation and Calibration: never used or once a year

. Set Work XYZ : not useful and ruins a job

. Set X, Set Y, Set Z, Set A : not useful and ruins a job

. Go to Zero: this causes hardware failures (broken bits, bent parts,...)The Goto Zero is particularly egregious since 100% of the time it causes either a bit to break or the head to smash into the bed. And it's an enormous button.

Finally, on my CNC I had the CNC custom interface installed and it won't disengage for 3.4rc1. How do I turn it off and revert to the rc1 gui?

Anyway, this is just my 2c. Thanks for constantly improving the product and taking feedback.

Mark

edit: I do use the Set X,Y,Z and A once or twice a session I guess. I just hand type the gcode but buttons are better.

-

@markz to give a little feedback the go to zero on the cnc panel executes /sys/workzero.g which gives you a way to provide a safe way to get to zero such as lift z to max, move, and then lower z as well (if you want).

In the settings there is an option to use the ui that is configured or force the setting between the two dashboards.

-

@sindarius Thanks for the reply. Using workzero.g is way better than forced to zero, thanks. Still, one way to view that is you're exposing one macro in a button and the button is really big.

Are all the other large buttons also linked to macros? I know Home is but Set ?

I'm seriously looking forward to having this new dual GUI and maybe adding another page or two for CNC stuff over time.

- I figured out how to get to the latest GUI after my CNC upgrade. I had to use the new update button in the GUI and that worked whereas the usual System page/upload did not (same file for both).

I totally forgot: please can we have a way to get more decimal points. In inches mode I position to .001 and in mm to .01. That's pretty standard. Some units support another decimal. Same is true for speed. On my mill it's not uncommon to run near 10mm/s and a decimal point would be welcome.

offtopic: I just switched my printer to inches (G20) and it seems to have crashed. 6HC/SBC. It's showing random spurious red error boxes and immediately disconnecting. ... Now it seems to be saying "DCS not started" after reboot.

-

@sindarius oooh I really like the timer bar on the messages. Nice touch.

-

@markz You'd have to thank Christian for that

-

@markz On the step buttons you should be able to right click and type in the step amount you want the buttons to execute.

-

@sindarius Yes, I've used that, thanks. Also, maybe to christian ->

the message boxes have been moved to midscreen - bless you : )

-

Updating a 6HC -> it appears that the RC1 misnamed the sDiap file for the 6HC to 6XD. I renamed it and used it just fine. Thank you for documenting the static IP change - a few seconds of tearing hair until I remembered.

-

@markz it should have provided IAP files for both the 6HC and the 6XD. The two binaries are similar enough that each one is likely to work on the other board except for the LED indications.

-

@dc42 Oh, thanks. I'm glad it worked for me as is (oops).

On another note... the mid-center message is important enough that I updated my mill to RC1 and the first job well,... I usually design in mm and manufacture in inches and the job interpreted the numbers as mm even with a G20 in-file (and I compared the gcode to a prior job and the headers were the same). When I had Fusion generate the same data as mm the job ran fine. Luckily I have a physical E-stop.

-

@markz said in 3.4rc1 early feedback:

@dc42 Oh, thanks. I'm glad it worked for me as is (oops).

On another note... the mid-center message is important enough that I updated my mill to RC1 and the first job well,... I usually design in mm and manufacture in inches and the job interpreted the numbers as mm even with a G20 in-file (and I compared the gcode to a prior job and the headers were the same). When I had Fusion generate the same data as mm the job ran fine. Luckily I have a physical E-stop.

Please explain what you mean by "the mid center message".

Note, object model values are always reported in mm; and each GCode source has its own inches/mm setting.

-

@dc42 Thanks for the reply.

The 'mid-center message' is moving the warnings to horizontal center instead of covering the macros. Seems dumb but really important on a tablet.

The object model isn't the issue. In my job, starting at 0,0,Z the bit was supposed to go down to just above material then rapid to one corner and then drop and start milling. Instead, it jammed the bit down to the bed and dragged it an inch or so. It was interpreting the data as mm as far as I could tell. Just regenerating the data in mm milled fine (and the script in the gcode file contains a unit-setter G20/21). Note I've been successfully milling in inches with 4.3 for months though I always keep the GUI in mm.

And to be clear I haven't retested and I think it was a units problem.

-

@dc42 I took a much longer look at the g-code and I don't see how it could be a units problem. The MinY is -1.8 which wouldn't have caused that gash in mm, so I guess I have no idea what happened.

-

@markz did the GCode invoke any system macros, such as homing macros, tool change macros, or the pause macro? When macros are invoked, the existing inches/mm setting will be used, unless you start the macro file with G20 or G21. Therefore, if you use G20 in your GCode jobs, it's best to use G21 at the start of every macro file (assuming you use mm in your macros) to ensure that values in the macro are interpreted in mm. The previous inches/mm setting will be restored automatically when the macro completes.

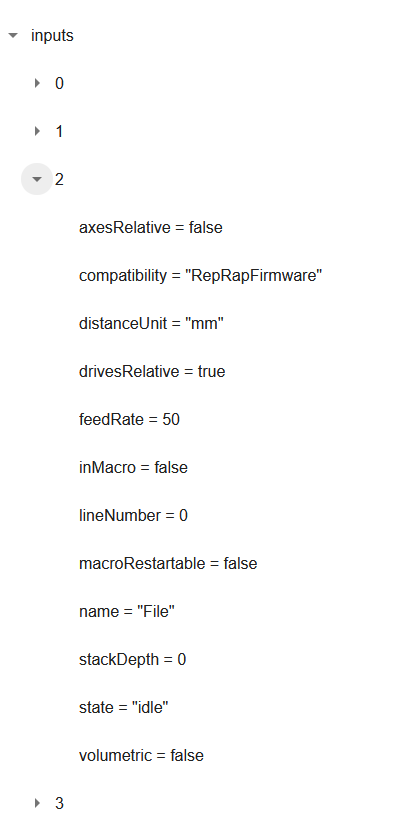

You can read the current inches/mm setting for each input from the object model:

-

@dc42 Thanks, that's good to know. I'll dumb-proof my macros.

Yesterday I ran a bunch of jobs using various unit settings and they all ran flawlessly, so... I'm going to put it down to user error for now.