Getting The First Print Just Right

-

According to the specs from E3D, their Titan Extruder motor has a rated current per phase of 1.4A.

-

Drop it to 855mA and look what happens. Raise the Current only if you are notice mssing steps or if the torque is not enough.

How long is your bowden Setup?

-

Direct drive.

-

If this is a direct drive i'm wondering why you use 5mm retract in your configuration. In my Bowden-Setup with ED6 Chimera (aboutr 60cm each) i'm only using 1.20mm.

But the questions in regards to "calibration" of Steps are still not answered. Have you tried to print it in PLA or PETG instead to proof the Settings and Mechanics are working and maybe only the Filament is bad?

-

-

I ran a 20mm cube. It came to X: 20.3, Y: 20.19, Z: 19.75. Not too shabby.

-

That does not indicate anything, cause "dimensions" impacts Steps of Axes and also Steps of the Extruder combined with Extrusion-Width. Therefore again: Have you ever calibrated your E-Steps/mm and have you tried to print the same with a different material?

-

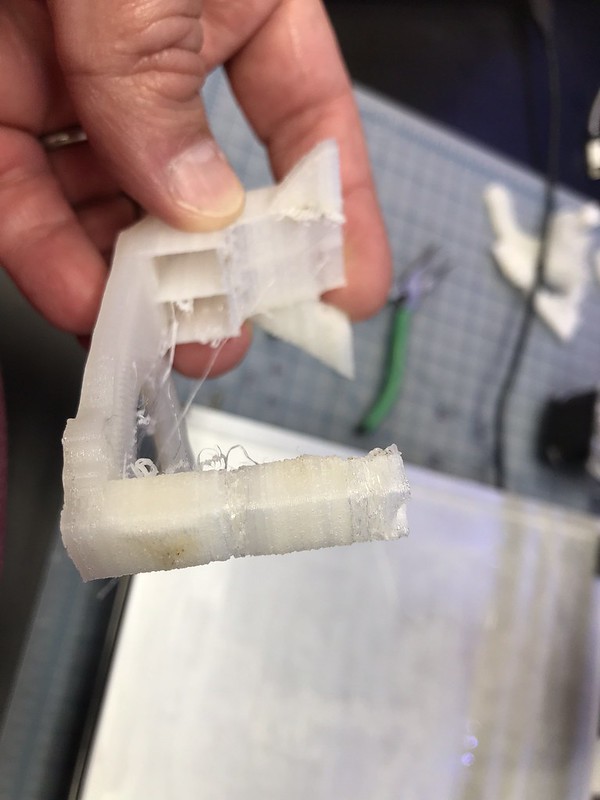

I calibrated my extruder; marked off 120mm, extruded 100mm, and adjusted accordingly. As for printing in another material, that's why I'm printing the fan holder for my extruder. I also have some Taulman n-vent and In-PLA, but I believe both require a fan. Does NinjaFlex require a fan?

-

I have no part Fan currently and still be able to print most every thing without any issues. Okay, stringing will happen for sure and sometimes not a perfect finish. But never so "ugly" as yours.

-

Why thanks. Any other suggestions?