Problem with calibrating axis

-

hello

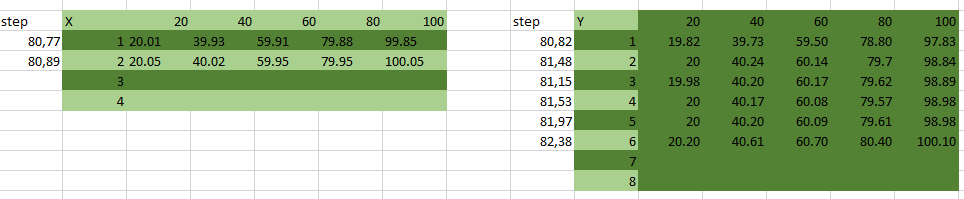

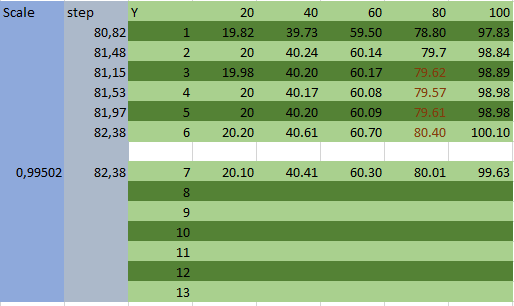

Im trying to calibrat my printers step/mm, I dont have any problem with Z and X. But Y is a hot mes it's either over or under the value i set.

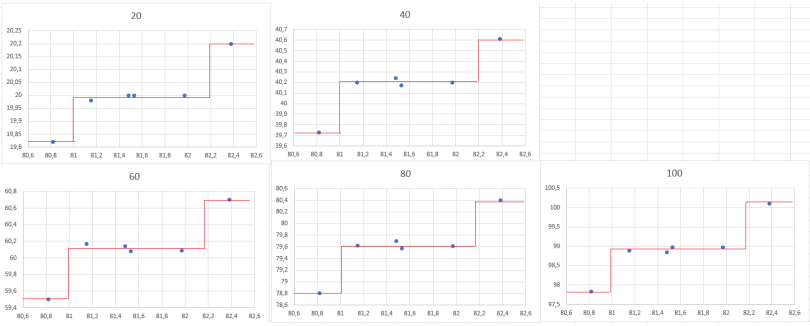

As you can see when i changes the steps the printed dimention stays relatively stabel until a serten piont ( im calibrating the 80 mm value).

Any suggestions ?

Grateful for all the help I can get.

dont know how helpfull this graph is but

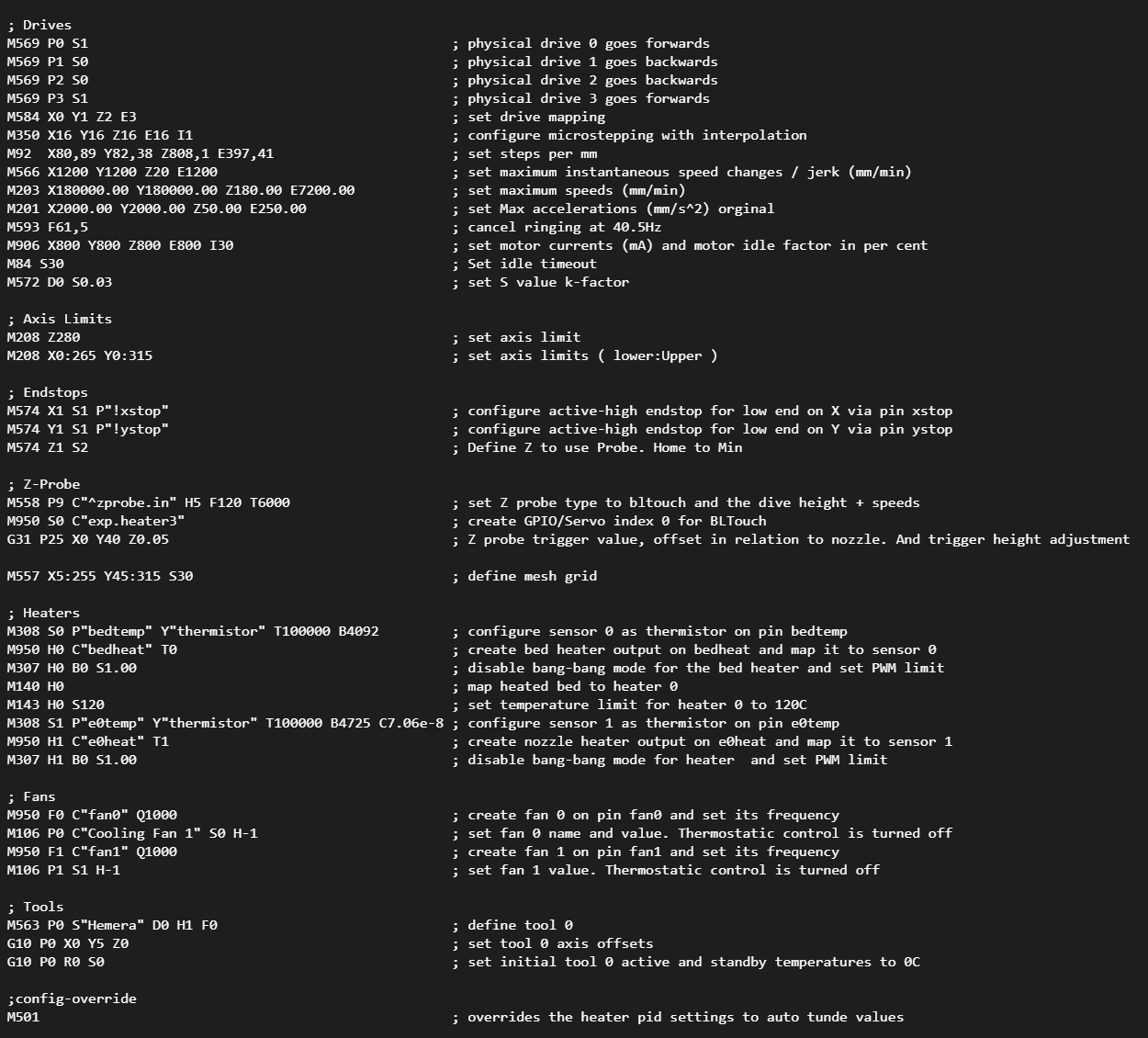

and hear is my config

-

Hi,

Interesting stuff.

Why should you be needing other than whole numbers for your steps/mm values. The hardware dictates what the value should be. What kind of hardware do you have?

Thanks.

Frederick

-

@fcwilt I have a JGaurora 5s printer moded with a duet2 wifi and a Hemera extruder. The XYZ motors are the 1,8 deg variant.

-

@thomasthetrain said in Problem with calibrating axis:

@fcwilt I have a JGaurora 5s printer moded with a duet2 wifi and a Hemera extruder. The XYZ motors are the 1,8 deg variant.

Well doing the math the correct steps/mm values should be:

X = 80

Y = 80

Z = 800

E = 400I need to double check that E value but I think it is right.

You can use command M579 to tweak the sizes of things - try using that and see how it works.

Frederick

-

@fcwilt I'll give this a try

-

@thomasthetrain

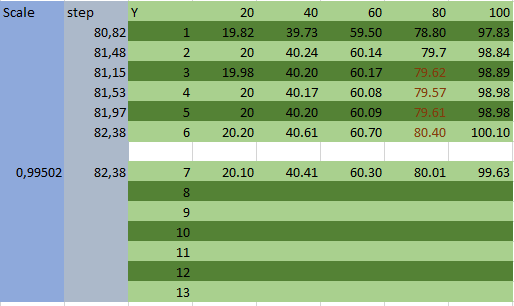

I've printed with M579 and this is the result, now the 80 mm is perfect but still not the rest.

thanks for the tip but because the differens in dimentions is not linear i can't apply M579, ( I Think )

-

@thomasthetrain said in Problem with calibrating axis:

@thomasthetrain

I've printed with M579 and this is the result, now the 80 mm is perfect but still not the rest.

thanks for the tip but because the differens in dimentions is not linear i can't apply M579, ( I Think )

Well if it is non-linear that would lead me to suspect a hardware problem.

Those steps/mm numbers are correct so it must be something else.

You have the stepper currents set to 800. The would be appropriate if the steppers were spec'd at a max of 1000. Which doesn't seem likely.

Try upping the current to a max of 80% of the stepper rating. Maybe the steppers are just missing a micro-step here and there.

And the max speed setting of 180,000 seems rather high - that works out to 3000 mm/sec

Oh yes, one other thing - always put the M92 command before the M350 command and be sure the M92 command aris correct for X16 micro-stepping.

If you do that you can then change the settings in the M350 and the firmware will do the appropriate calculations for adjusting the steps/mm.

Frederick