Filament Sensor Says -3% as Min

-

Hello, I am currently in the middle of printing a part, and the MFM I have hooked up to my printer, pauses the print. I rand M591 D0 when it paused and it said:

Duet3D rotating magnet filament monitor v4 on pin e0stop, enabled, sensitivity 28.80mm/rev, allow 60% to 160%, check printing moves every 3.0mm, version 4, mag 130 agc 92, measured sensitivity 26.19mm/rev, min -3% max 110% over 66.9mm

Does the -3 mean a retraction, and if so how do I allow the filament sensor to allow retractions?

-

Can you share your full config for the filament monitor?

How much retraction are you using? How much pressure advance?

Firmware version?

Is there any indication of slippage?

-

@tratoon said in Filament Sensor Says -3% as Min:

Does the -3 mean a retraction, and if so how do I allow the filament sensor to allow retractions?

Negative values usually indicate the extruder skipping steps or a filament backslash if pressure in a bowden setup becomes too high. Another reason may be a varying distance between MFM and extruder. Retractions need no special treatment, they are properly calculated by the firmware. If the MFM goes smooth and none of the above mentioned effects apply, my readings are 100 ± 3 or 4 percent.

-

@Phaedrux Answers to your questions:

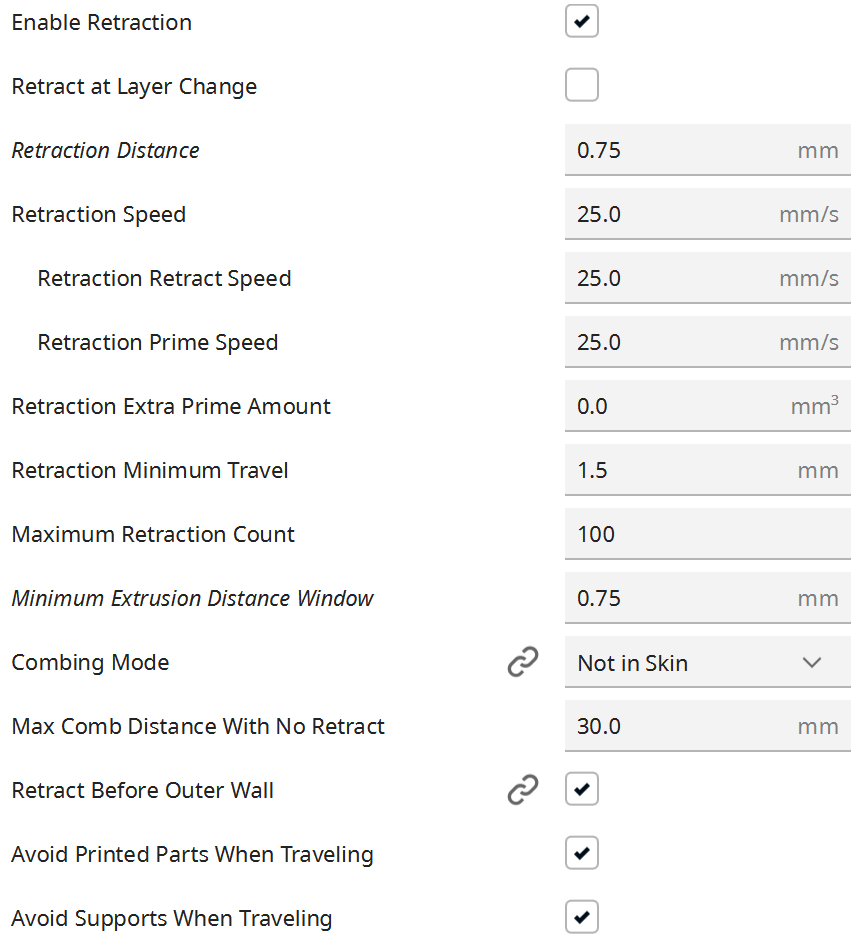

Config:; Filament Sensor M591 P3 C"e0stop" S1 D0; filament monitor connected to E0 endstop M591 D0 ; display filament sensor parameters for extruder drive 0Retraction Settings:

No indication of slippage, using LoFi's MFM housing, so balanced amount of tension on the filament

I am Using E3D's Hemera in a direct drive set up, my MFM is about 5mm away from my extruder

-

@tratoon Can you reproduce major deviations (don't need to be negative) from 100% in the MFM readings with a test print? If yes, repeat that print with reduced speed - something like 50%.

As slippery filament (e.g. PETG) can be a reason for the reported effect, too: can you try another type/brand?

Finally, you can increase the distance for checking print moves: now, it's every 3 mm - try 5 mm instead.

-

@infiniteloop Yes, I have gotten 30%, 20%, and some other ones. I use PLA from GST3D, which is decent quality filament. And yes, I will change how often I check printing moves. Could I get away with 10mm instead of 5mm?

-

Could I get away with 10mm instead of 5mm?

Maybe. But PLEASE don’t reply in your other thread. Stay with this one.

I use PLA from GST3D, which is decent quality filament.

Nice to know, but that's not my point. Please refer to my last post. There, I listed some potential reasons who can result in negative readings from the MFM:

- Print speed (affecting filament flow / nozzle congestion)

- Slippery filament (I don’t talk about filament quality)

- Varying distance of extruder / MFM

IMHO, if all those things are covered, there’s just one culprit left: the mechanics of the MFM. Double-check the filament path (in the MFM), ensure the idler moves free, and test rotation of the hobbed assembly: use a felt marker to tag the axis so that you can visually monitor its movement.

One last thing: have you attached a bowden tube to the MFM on the „incoming“ side? If the filament enters the MFM with an angle, you might miss steps, too.

To conclude: the misreadings are without doubt caused by some mechanical issue. My list of potential pitfalls is rather comprehensive, now it’s up to you to figure out the culprit.

-

@infiniteloop Yes, I have a Bowden tube on the incoming side. How do I tell if filament is slippery? And are you using the MFM too, if so, could you share your config and what mount you are using? The rotation of the assembly is fine too. I will try changing speed next.

-

@tratoon That’s my MFM - nothing fancy, it’s the „original“ housing design which needed a lot of filing. Inside the chamber, I use a bowden of approx. 500 mm length:

Here’s a thread where I detailed at which mechanical parts to have a second look. @Lo-Fi 's design is a bit more forgiving, it didn’t exist at that time.

This is from my config:

; Magnetic filament monitor(s): M591 D0 P3 C"e0_stop" S1 R70:120 L26.9 E3.0 ; D=extruder 0, P=sensor type, C=e0 endstop, S=enabled, R=70% to 120% tolerance, ; L=sensitivity 26.9mm.rev, E=3mm detection lengthHow do I tell if filament is slippery?

If the problem disappears with another filament, you got there. But first, mark the axis of the hobbed assembly and observe how it rotates when you push filament through the MFM.

The rotation of the assembly is fine too.

Please check this twice, it’s fundamental.

-

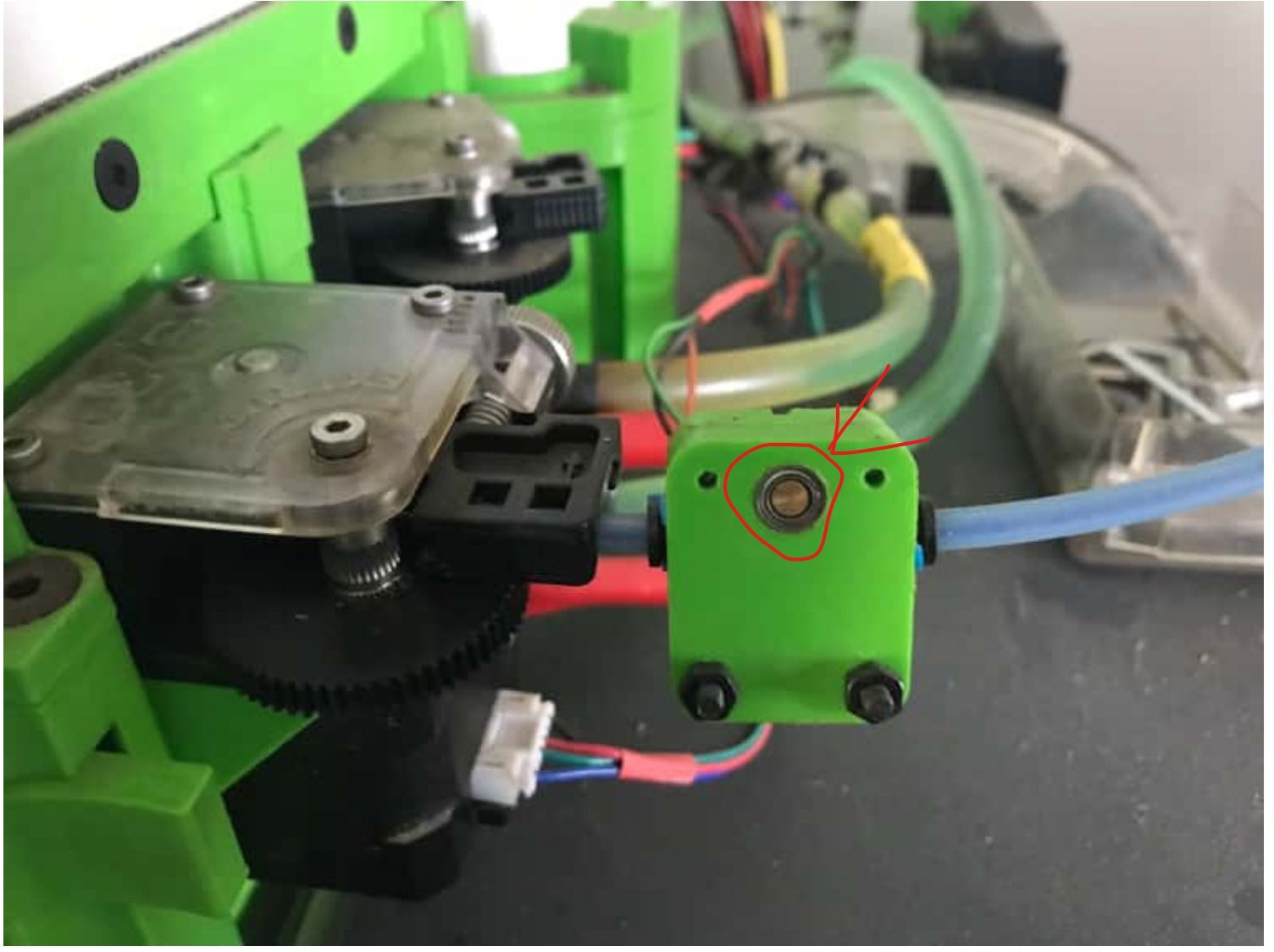

@infiniteloop You would like me to mark this part right?:

-

@infiniteloop I'm sending a video of the assembly turning:Compressed MFM Hobbed Assembly Video MP4.mp4

-

@tratoon said in Filament Sensor Says -3% as Min:

You would like me to mark this part right?

Right. Saw your video, too: looks good. And I assume that you got your config right. On top, the readings you report from the MFM tell me that transmission from sensor to controller works.

Well, that's exactly the problem: everything looks OK, although something - obviously - goes wrong. To narrow down on this, I decided to exclude erroneous reports (i.e. firmware problems), because the typical symptoms look different: No values transmitted, "sensor errors", etc. …

If I understand it right, you get these strong deviations of more than ±30% somewhere during a print - that's what lets me think of a subtle mechanical problem. Tracking that down is tedious, I can only name the typical suspects. Everything else depends on your intuition and your fingertips - something I can't help with from a distance. What makes things even worse: I can be totally wrong.

TBH I have no more rabbits to pull out of my hat. Either you got an idea which traces to follow, or you have to wait for fresh ideas from someone else.

-

@infiniteloop I've seen some interference issues too. In my testing, I found that having the sensor cable too close to the extruder wires would couple cause wacky readings. Move the wiring apart and it all went away. I've not got around to testing shielded cable, but I suspect that would help. Might be worth a try here?

-

I found that having the sensor cable too close to the extruder wires would couple cause wacky readings.

Hi lo-fi! That's true, but at least with my printer, I only got either no readings at all (that is: zero movement) or those "sensor error" messages.

Might be worth a try here?

Absolutely! If @tratoon can't find mechanical issues, you come to his rescue. So thx for joining the party

-

@infiniteloop I just ran another print and the sensor worked flawlessly. I will try the print that had the sensor issues, and see if that works.

-

the sensor worked flawlessly

Hm … maybe with your MFM housing, you caught Schroedinger’s cat?

-

@infiniteloop I just ran the print and no issues, I changed it to check moves every 5mm maybe that fixed it not sure.

-

undefined TRATOON marked this topic as a question

undefined TRATOON marked this topic as a question

-

undefined TRATOON has marked this topic as solved

undefined TRATOON has marked this topic as solved

-

-

undefined infiniteloop referenced this topic

undefined infiniteloop referenced this topic

-

undefined infiniteloop referenced this topic

undefined infiniteloop referenced this topic