PrintNC & a heated mould for "precious plastic" formwork bricks

-

In early 2021 I decided that I was going to try to produce formwork (for poured structures such as concrete) out of recycled plastic bricks. This was in part because I'd heard that there's timber shortages, a crisis in plastic recycling, and I always wanted to figure out what to do with my waste 3D prints. In discussions with concreters and other builders who use formwork, I was told that the resulting surface finish of the structure was a very important consideration when selecting a material for formwork. This is why formply, with it's smooth exterior laminate is the industry standard, even if it rapidly becomes a waste product.

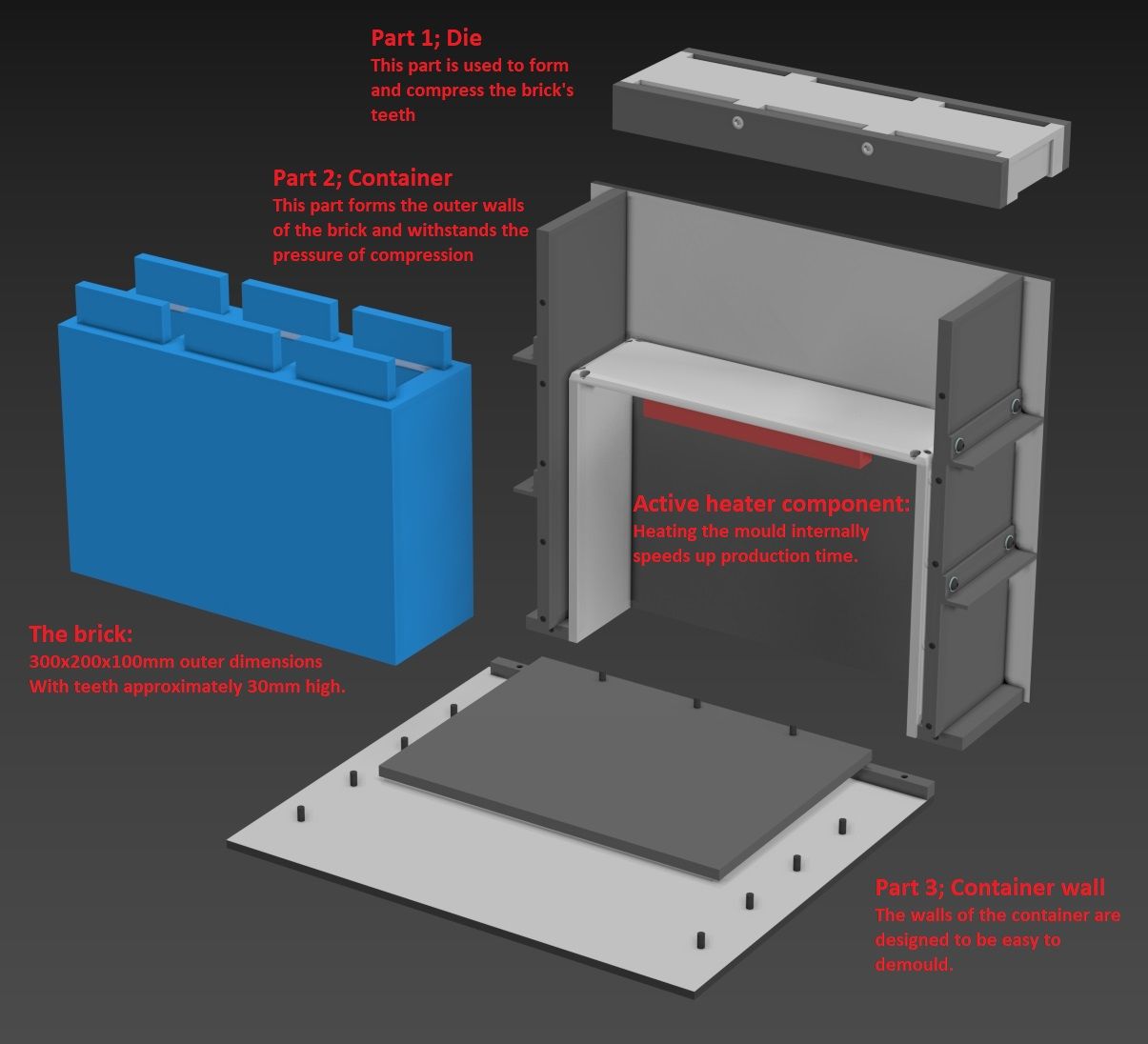

This lead me to come up with higher specifications for tolerances & surface quality than the original, open source brick tooling designed by Precious Plastic. However I was determined that the geometry of their brick was still suitable for formwork, with the addition of a compression step, and more precise (machined rather than welded) parts.

As a result I started work late last year in building a PrintNC specced to my project, with hardware that I am familiar with (Duet). This week, using steel I milled and cut on the PrintNC I was able to produce my first "early production brick"*.

The mould's design is simple to replicate, costs less than $300aud, $200usd, 170gbp, etc. and can produce bricks without additional tooling, with nothing more than your body weight and some** heat.

*that didn't break into pieces as I demoulded it.

**understatement.

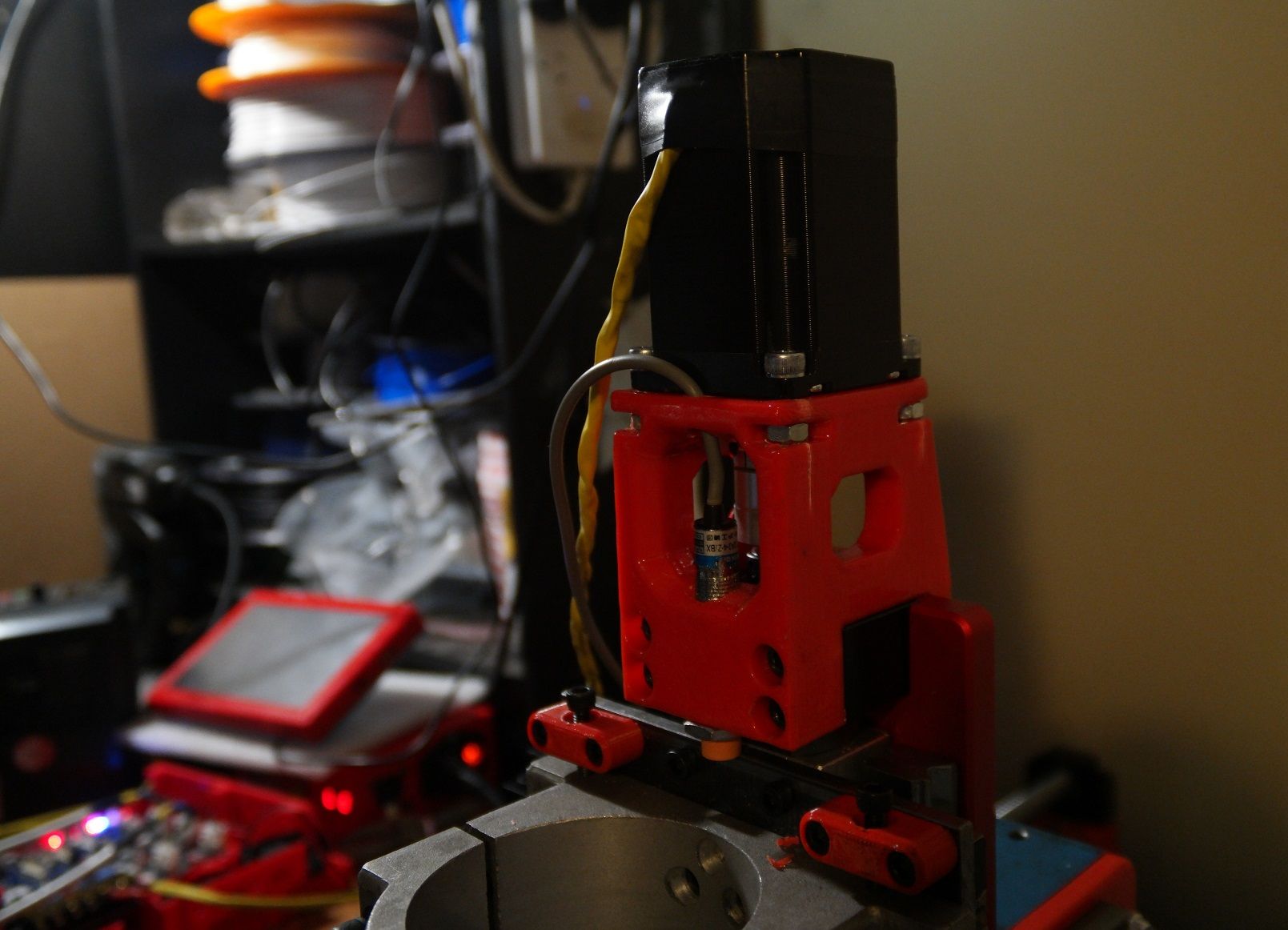

A motor mount I redesigned for my PrintNC, printed in solid ABS, with an acetone coat.

Potato quality photo of a drilling operation.

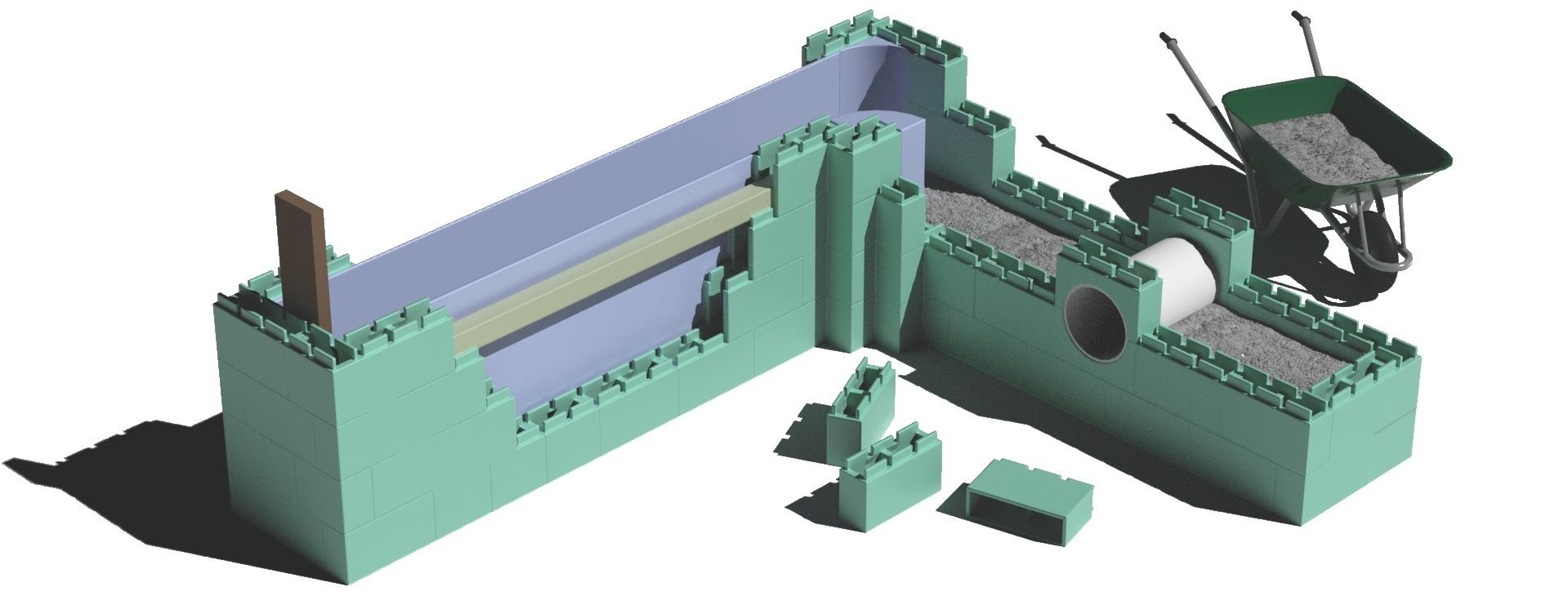

Concept render of the intended use of the bricks.

Explanatory render of the tooling.

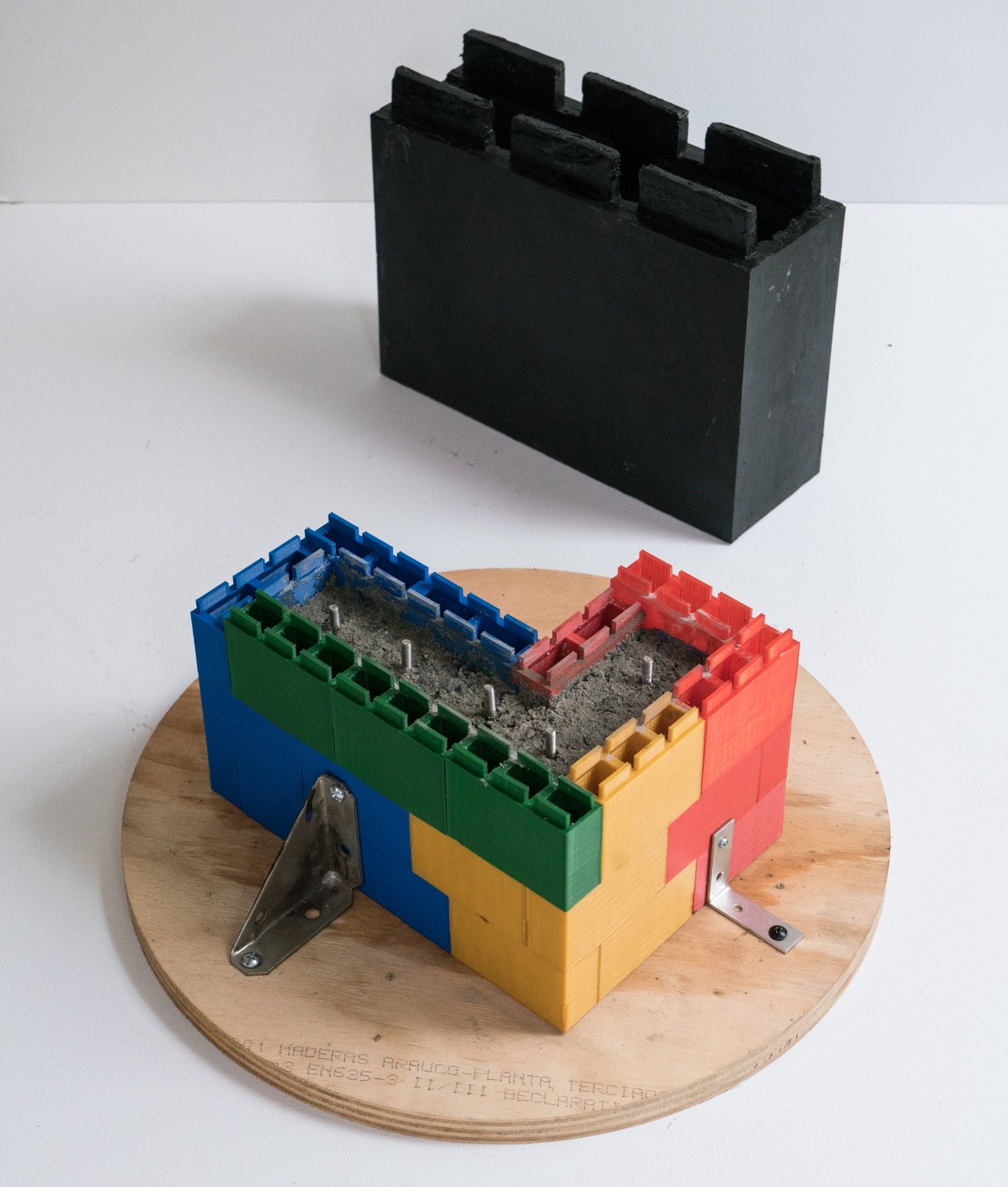

Photo of the early tooling used to produce the first brick. The internal plate is heated using regular 3D printer heater cartridges, and the side walls could be heated with heater pads.

The first brick, made out of ~2.1kg of waste PLA. Note the smooth sides and sharp corners of the external surfaces.

3D printed 1:4 scale model of the brick with poured concrete inside.

-

https://www.thingiverse.com/thing:5467974 - initial design, with a copy-pasted preamble from this forum post. Bill of materials, basic instructions and STL of basic tool dimensions is included.