>15 axes via 3HC expansion boards

-

Posting here as per @dc42 suggestion here.

I have two machines running Duet 3 main boards plus 4x 3HC expansion boards as part of a custom CNC motion control system. I currently use all 15 available axes, 13 of which are used for part feeding.

As we're firmware limited to 15 axes (main board + 3 expansion boards) I'm unable to utilise my 4th boards (axes 16-18) on both machines for further part feeding.

Is there any idea about whether >15 axes will be implemented? I can't find it now but I think I read somewhere on the forum that it was perhaps proposed for the 3.5 release.

Thanks in advance.

-

@TechnomadicJim that looks an interesting machine! Can you tell me a little more about how you operate the part feeders? Do they move mostly in one direction? Do they have homing switches? I am wondering whether they might be handled more easily as extruders instead of as axes. RRF on the 6HC allows up to 16 extruders already, and up to 25 axes+extruders.

-

@dc42 Thanks

The part feeders use sensorless homing for the four steppers that run off the 6HC. The 3HC expansion board steppers use a min end stop only (not visible in picture). I would eventually like to use sensorless homing for the part feeders on the expansion boards but this works fine at the moment.

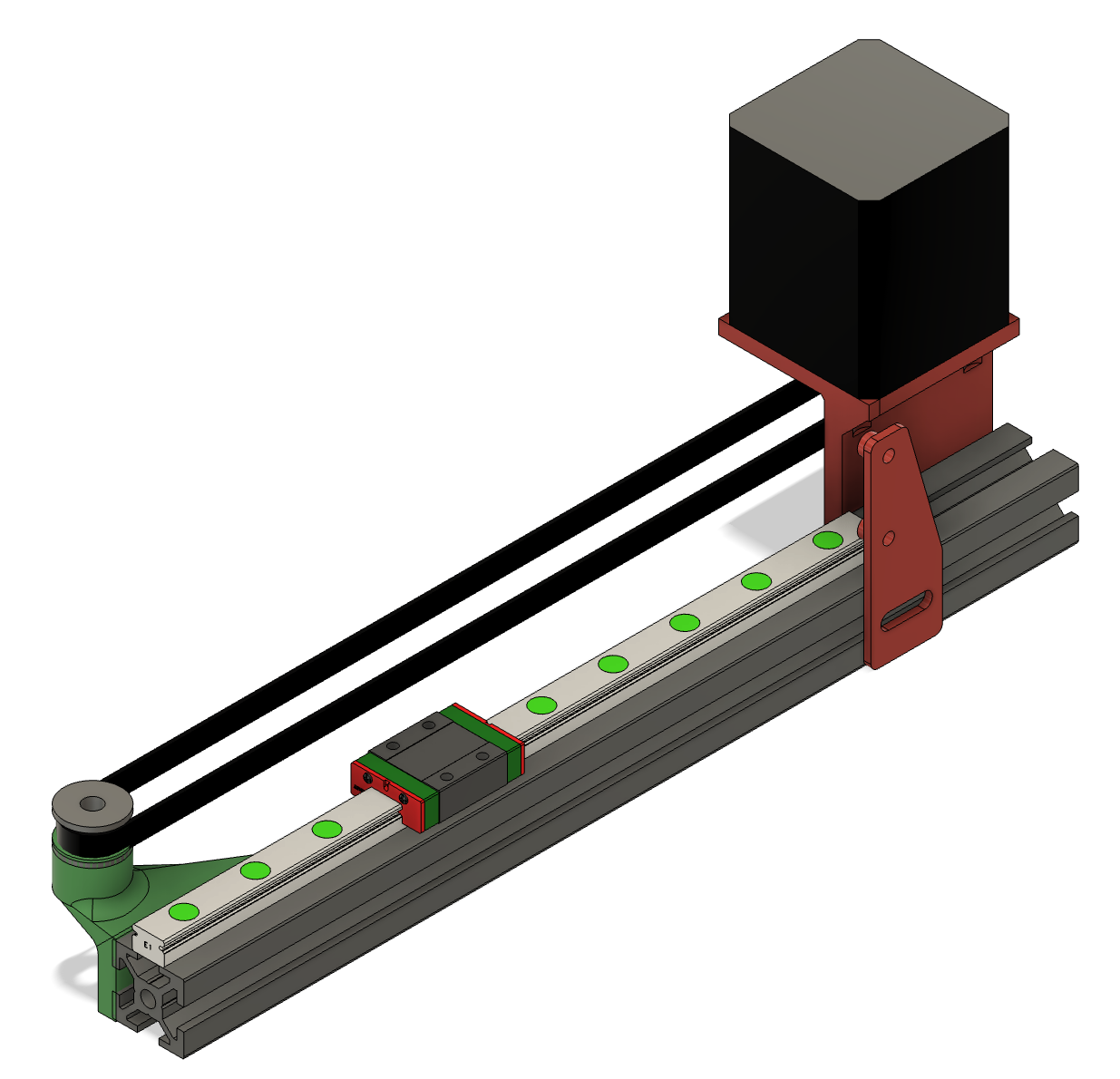

The part feeders use sensorless homing for the four steppers that run off the 6HC. The 3HC expansion board steppers use a min end stop only (not visible in picture). I would eventually like to use sensorless homing for the part feeders on the expansion boards but this works fine at the moment.To give you a better idea, here's a partial CAD model of the parts feeder.

The parts are stacked up on top of each other in an enclosure and drop into a recess shaped like the part once it hits it's min end stop. It then moves in the opposite direction to present the part for the next process.I didn't think of the 25axes+extruders possibility. That's an interesting idea. I suppose an extruder can't have an end stop so that's why you ask if I have homing switches. It's not ideal but I might be able to make it work without an end stop for the time being.

-

@TechnomadicJim sensorless "homing" is implemented for extruders on main boards already, although it's been a while since I tested it. Basically, if you do a G1 H1 Exxx move it will stop before moving xx amount if/when the motor stalls.

-

@dc42 It's working! The sensorless homing does indeed work for the extruders as suggested. Thanks again for the support.