filament sensor is marked as "disabled" in M591

-

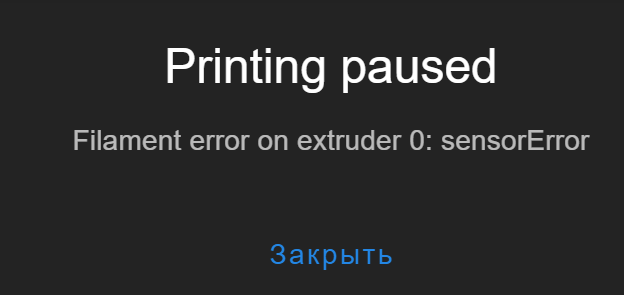

Hi! i have installed magnetic filament sensor 1.7b and have trouble make it working.

Basically what happens - filament is not stuck, but printer stops printing with 'sensor error'What is wrong with my simple config?

M591 D0 P3 C"e0_stop" E3 A0 R50:160 S1Duet2 WiFi RRF 3.4.4

M591 D0 shows

Duet3D rotating magnet filament monitor v3 on pin e0stop, enabled, sensitivity 28.80mm/rev, allow 50% to 160%, check printing moves every 3.0mm, version 3, mag 117 agc 128, measured sensitivity 37.34mm/rev, min 25% max 119% over 15.1mmwhen

-

@c310 In my experience, this is typically a wiring or interference issue. Either way, communication has been lost with the MFM during the print. How do you have the wires routed?

That minimum movement figure looks suspiciously low too. That's a separate issue and means that the filament is either slipping in the extruder, or more likely not moving the rotating assembly in the MFM. What housing are you using?

-

-

@c310 mag is a little low, AGC is a little high but it should be workable. Try my redesigned housing from the sticky thread in this forum, it'll probably solve the filament skipping past. It'll print fine on an FDM printer so long as the instructions are followed.

The wiring is sensitive to interference no matter how good the continuity might be. How is it routed? If it's close to stepper wiring it's caused communication errors for me. Screened cable seems wise - USB cables are a good cheap source that everybody has. Don't forget to ground the shield only at the board end!

-

@c310 agc should be <100. I would check the assembly and potentially smooth the bottom of the lid part so the pcb sits slightly closer to the magnet.