Mixing 400 and 200 step motors

-

So, apart from changing M92 and adjusting currents not much is needed in reagards to mixing 400 and 200 step motors, correct?

(I seem to have a broken 400 step in my delta, and I only have 200 steps around as potential replacements while waiting for delivery of a new 400 step)

-

@janjoh the main restriction is that when an axis uses more than one motor, the motors must have the same number of steps/mm.

I've never tried running a delta with towers having different steps/mm, but I think it should work although it may perhaps leads to some strange artefacts. You could try using double the microstepping on the 200 step motor.

-

@dc42 THank you.

I have a strange issue. I suppose I that i COULD yank all three and replace them with 3 x 200. Would you say that to be "Less bad" then mixing?

I have a mechanical noise that albeit strange, by the power of deduction must come from the motor. SO I want to yank it to see.

What I mean with strange is that I am having a hard time pinpointing it other then "right tower kinematcis".

It's a sort of a grinding noise but only seem to happen on a certain section of the rail.First I thought it was a top idler bearing. But that seem to have been a red herring, as I have replaced the bearings and it did not help.

Next I thought "it's the bearing block!" So I removed that. Only to find that i could still hear the noise while moving the now assembly that was still on the belt.

WHat reallllly bugs me is that I can not pin point the location. I have even used a mechanists stethoscope (great tool for many things) without being able find the bleeping source of the noise.

I can not see the logic in such a noise only appearing on parts of the distance, when both motor and idler having spun sveral revolutions to GET to the affected distance unless the noise was caused by the rail/block.

-

@dc42 Actually I did, I have one prototype with 200 and 400 step motors mixed together, no problem at all. Works on RRF3.4.0

-

@janjoh I agree it's most likely caused by the rail and block. However, if it only occurs at a particular speed then it could be that a motor mid-band resonance is excited at that speed.

-

@dc42 It also seems focused when the rear tower operates about 10cm from the bottom of the rail. BUT as I said. If i remove the block (remove screws and move the block to the bottom of the rail and move just the Robodigg carrier with the still attached carrier plate, I can still hear SOMETHING when manually traversing that area.

The sound is ill suited to be captured on video else I would have presented a nice video.

Now, since the sound APPEARS to not be connected to the block or rail, logic dictates top idler (bearings have been replaces) or the motor assembly. RIght?

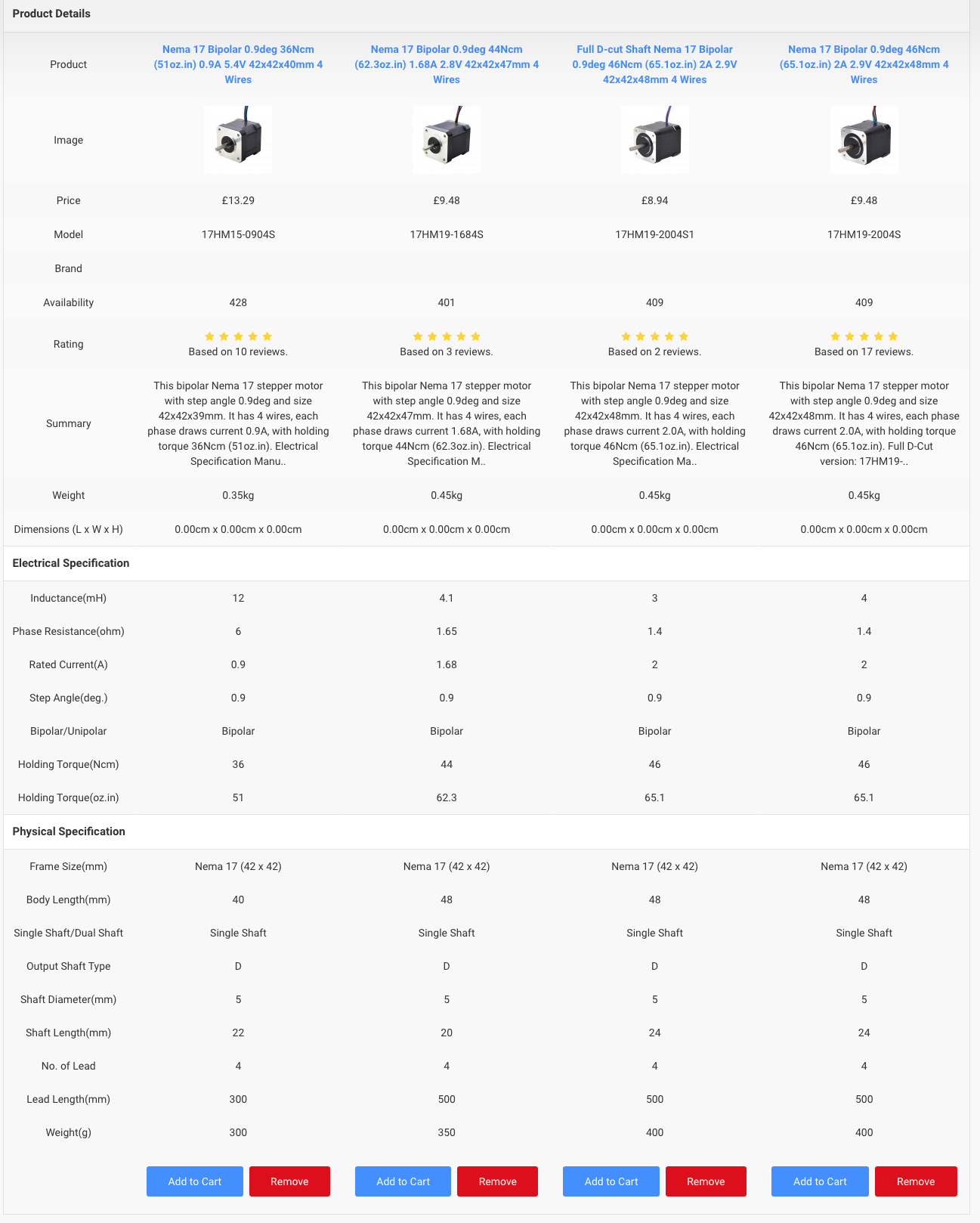

Regardless, I think I want to order at least one spare motor. WOuld you care to offer a recommendation between these? Delta pretty close to spec to you venerable "high precision delta" of bloggs past

I'äm leaning towards the 200D4S1 as I beleive "low resistance/inductance" is still desireable?

-

@dc42 After a period of too much work and a week of "flulike mancold symptoms" I am back at it.

TL;DR: You are certainly correct about motor resonance, but I am a bit confused.

I decided to go over the whole machine with a mechanist stethoscope and look for undesired noises everywhere. I found a few.

-

Frayed belts rubbing at the "guides" of the Robotdigg idlers. (changed them to toothed idlers with spacers as outlined in a different post), also replaced all belts.

-

two linear blocks had lost a few balls. Removed, cleaned, regreased, replaced balls.

-

Power supply seemed to pick up vibrations, so i isolated it with silicone dampeners. (It was just screwed down onto the aluminum base plate of the machine.)

But I still had some resonance.

So, I decided to drop the motor currents from 1100 -> 800. And.. That did the trick mostly. Some moves still cause a bit of resonance.

"AHA! i thought, it IS a bad motor!" so, I started to move ONE motor at a time back to 1100 .. but increasing the current for any motor reintroduced the resonance.

While I think I understand the concept about resonance, I am trying to figure out why this has started to happen on a machine that didn't use to have this behaviour. I mean, wear and tear certainly, but what might have introduced this issue in all motors at the same time?

The motors ARE suboptimal, they are unnecessarily large. they are 60mm motors ( 42HM60-1684). But that is because there was a bit of a mixup when I ordered them, and the seller pretty much ended up giving them to me as to not do a re-send of them.

The motors are mounted with one of those "cork dampener sheets". I opted to not use the "rubber mounts" as the belt tension in my experience makes the motor tilt slightly and the belt thereby wanting to rub the outer limit of the drive wheel.

-

-

I FOUND THE LAST NOISE!!!!

And I am just groaning now.

So, I tried to mount one of the rubber stepper dampeners just out of frustration. Just to try something new.

When assembling it, I realized that every time i brushed or plunked the X-tower belt, the noise was there. Every time.

I now decided to not touch ANY moving parts, but systematically listning after the source of the noise.I went over the entire frame and could not pin point it. While listening to the upper part Z tower I realised that the sound was not coming from there, but actually from my other ear. Which was really turned towards the bed....

And the effector...

And the fan on it...

Gently touching it...

Silence...

In hind sight, I do not understand why I thought that that fan could not be the source of THAT kind of noise, It just sounded to metallic in my ears...

And here's the culprit.

https://www.youtube.com/watch?v=K9sxuzjJ0eEI feel so stoopid now... Time to reassemble everything back to what it was. But in all fairness, going over the machine was needed...

-

undefined Phaedrux marked this topic as a question

undefined Phaedrux marked this topic as a question

-

undefined Phaedrux has marked this topic as solved

undefined Phaedrux has marked this topic as solved