Heater 1 fault: failed to read sensor: badVssa

-

I've just started getting the fault "Heater 1 fault: failed to read sensor: badVssa" on my toolboard LC1, and the temp shoots up to 2000C.

After resetting the board the temp reverts to the correct value.I have noticed that the error always occurs at the start of the 2nd layer, no matter how fast or long the first layer takes to print. I've tested with old files that have previously printed fine.

I have also left the printer idling at 220C for 30 mins with no error, only for it to happen as soon as a 3dbenchy hits layer 2.

I've tried both temp inputs on the 1LC, both have the same behaviour.Does this sound like a thermistor problem, or a board fault? thanks

-

@nick9one1 It sounds like you may have an intermittent short between Vin and the thermistor. Better check your wiring again and perhaps try to replace the thermistor

-

@chrishamm thanks. Just swapped the thermistor out including a new JST ZH connector, but I still have the same issue.

While I was testing, I notice a complete break in the circuit causes the temp to read -273, and a dead short reads at 2000C. So It does look like a wiring issue, but I can't see how I can still have it with a new thermistor

-

@nick9one1 46cf078a-f2e2-4dd5-a0c5-c40437b87824-20240422-1131-39.9347558.mp4

It looks like it might be related to the part cooling fan, which is why it happens at layer 2.

Disconnecting the part cooling fan allows the print to finish -

I've installed a new part cooling fan, and the problem persists. I think the issue is with 'Out1'.

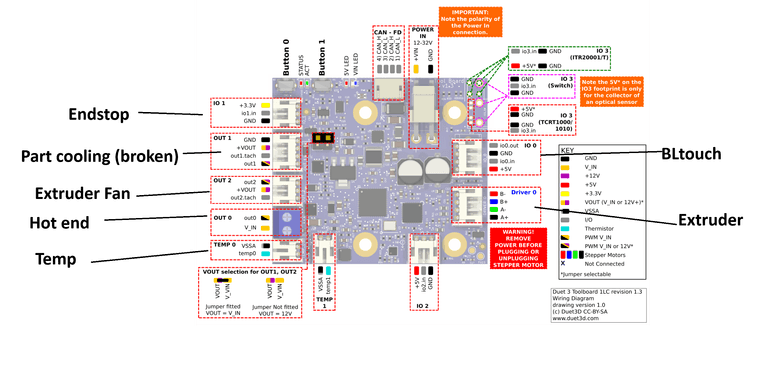

this is my current setup;

Would it be possible to move the hotend/extruder fan to IO2?

thi swould free up out2 (which seems to have speed control) for me to connect the part cooling fan? -

@nick9one1 the "bad Vssa" message normally occurs only when there is a short circuit between the Vssa pin on one of the thermistor connectors and something else. Most commonly this is caused by a short between the thermistor and the hot end heater. In your case it sounds as though there is a short between Vssa and the signal wire that controls the print cooling fan. Check that you don't have any metal swarf on top of the tool board that could be causing a short, or a metal washer on either side of any of the tool board mounting holes that you are using.

IO2 cannot provide enough current to run a fan.

-

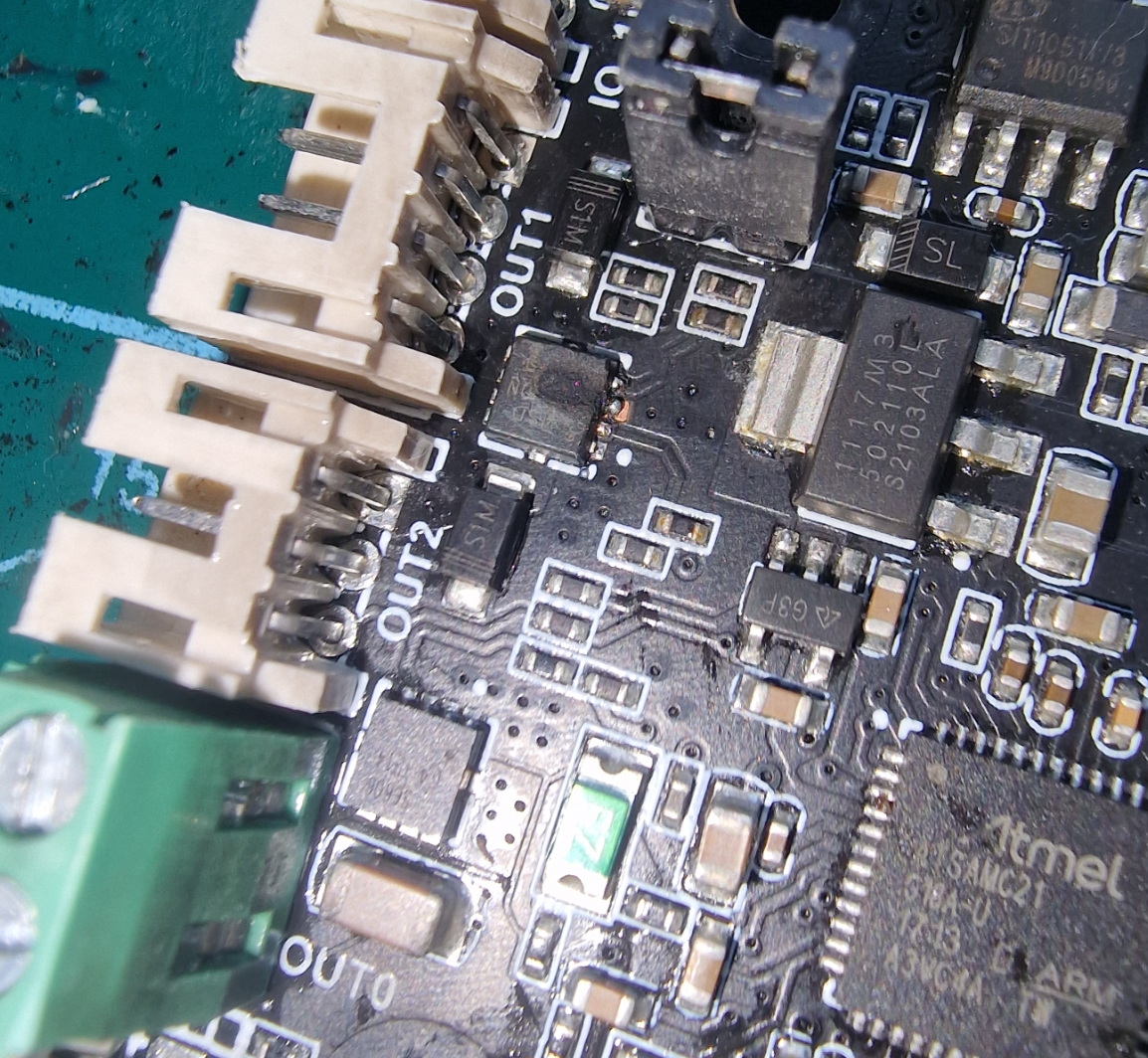

@dc42 Thanks. I've pulled off the 1LC to clean with IPA. I think I've spotted the problem.

It looks like something has caused the IC controlling Out 1 to blow.

I can move the part cooling fan down to Out2 to reatin PWM but it sounds like there isn't anywhere else on the 1LC for the extruder fan?

As far as I can see, my options are to connect it to VIN (it will obviously always be running).

Wire it back to the main board

Replace the 1LC.Can you suggest anything else I've missed?

-

@nick9one1 yes the dual mosfet that controls OUT1 and OUt2 looks blown. I was about to offer you a warranty replacement because the soldering on the second pin down from the right looks bad; but on further inspection I see that this tool board was not manufactured by Duet3D.

-

@dc42 I wonder if that pin became dry when it overheated, as I have had it installed for at least two years without issue.

I hadn't realised it wasn't manufactured by you guys. I might wire the fan back to the mainboard for now while I order and wait for a genuine board to arrive. -

@nick9one1 said in Heater 1 fault: failed to read sensor: badVssa:

I wonder if that pin became dry when it overheated,

Unlikely. It's clear that the solder never wetted that part of the pad that is exposed. OTOH it cold be that the bad soldering caused the mosfet to fail.