I need to allow my max travel to move 4mm past my endstop

-

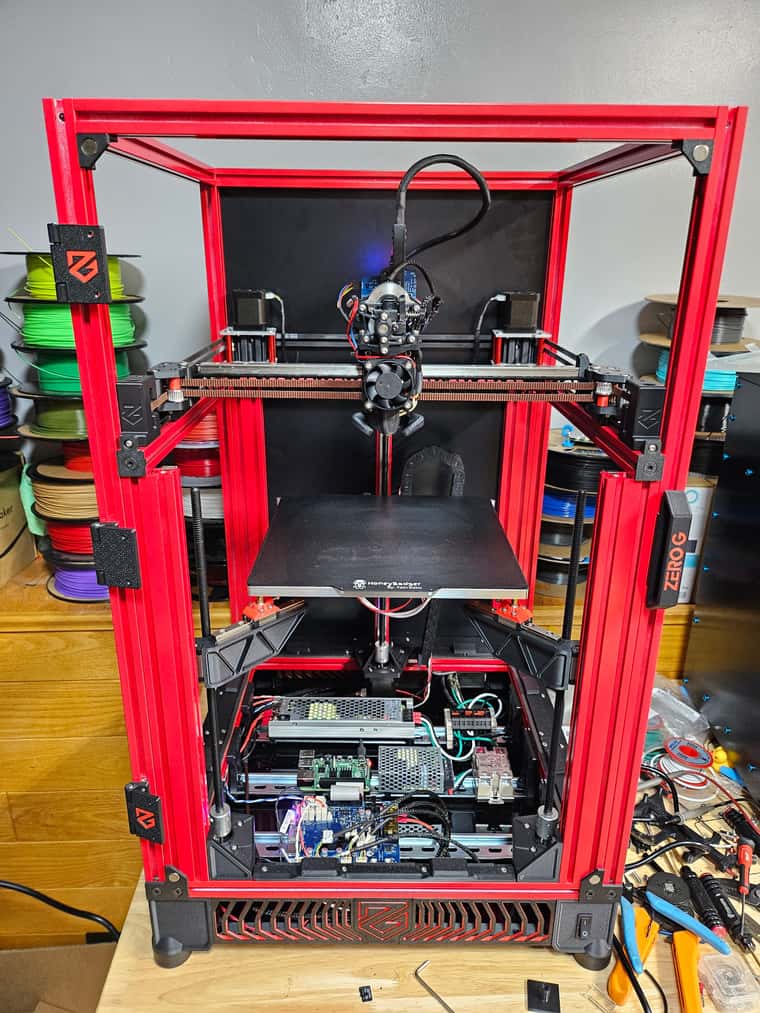

Added a picture of my y endstop setup and a overall picture of the printer in its current state. Still need to finish some wiring and finish wire management. Had to cut some zip ties as I didn't have my steppers wired properly the first time.

-

@turtlecrawler currently the easiest way of doing is to use M208 in your homing file to temporarily change the axis maximum to the endstop position before performing the homing moves, and change it back again after the homing moves.

-

@turtlecrawler Set the Y axis maximum with M208 Y264, home the axis, then after it backs off 5mm from the endstop (usually after a second, slower homing) send a G92 Y253 (ie 258-5) to set the Y axis position.

Post your homey.g and homez.g if this doesn't work, perhaps something is overriding the Y axis position in homez.g.

Ian

-

Awesome, so I was on the right track. But I was trying it after homing.

I will try that before the homing commands after work.

-

@turtlecrawler May not be kosher but how I do what you are describing is

M564 H1 S0 ; Allow movement BEYOND X & Y axes boundaries.

M564 H1 S1 ; Restrict movement to within axes boundaries (for normal X & Y movement)

edit, I use H1 as I have already homed X and Y and want to reach the rear of a plus size frame.

Z does not matter since the beam does not move in that direction.More edits , oh and hi traveler from the Zero G forum I think.

My project from there is done and working well.

But since projects are never really done I bought a frame kit from DLLPDF and am slowly getting it ready for the big move. -

@gtrider That might be a even better solution, as I only need to enable this move for the sex bolt. And then I would only be giving it this extra travel when needed.

The enclosure frame project is my creation. I Tossed around a few ideas for enclosing the Mercury 2-3 years ago and first enclosed my 5 plus. I took what I learned from that and refined it a bit more.

-

One thing to note if you are using M564 as @gtrider suggests.

I assume you'd be moving back withing limits before sending the M564 H1 S1 command to re-establish limits. It's a good practice to send an M400 command before that M564 H1 S1. If you don't, it's possible that the machine will still be traveling, but not yet in-bounds when the M564is processed and the fw will think there is a bounds violation. all further moves will get a warming and be ignored. I learned this on the hard way.

-

@mikeabuilder Thats a good reminder, I'll make sure to move it back within the max travel after finishing my z probe.

I probably spend close to 2 hours trying to figure this out last night. It was a good exercise in doing some quick config edits and testing various things out.

After spending the past 3 years with klipper, moving to something else has been a challenge. But at the same time I have become much more comfortable editing configs then I was when I setup a Duet 2 wifi on my old hypercube.

-

@mikeabuilder Yes I return to the original position then issue the M564 H1 S1. Never tested to see what would happen if I did it before then and it sounds from your experience like it is good I did not try.

One thing to make sure of if you do this is your movements do not exceed the limits of the machine. It can make some interesting noises if you do. I reversed one movement by accident as it was being set up.

-

@turtlecrawler If it has been awhile then you may not have had the Meta commands to play with. You can do some fancy coding now.

https://docs.duet3d.com/User_manual/Reference/Gcode_meta_commands

-

Ended up writting it as a macro, so I can call it any time I need to probe the nozzle.

; nozzleprobe.g var NozzleMaxTravel = move.axes[2].max - move.axes[2].min + 5 ; calculate how far Z can travel plus 5mm M104 S160 G90 ; absolute positioning G0 X103 ; Move over sex bolt in the X axis M564 H1 S0 ; Allow homed axis to travel outside limits G0 Y261.0 ; Move over sex bolt in the Y axis M109 S160 G91 ; relative positioning G1 H1 Z{-var.NozzleMaxTravel} F600 ; coarse home in the -Z direction G1 Z5 F6000 ; move back 5mm G1 H1 Z{-var.NozzleMaxTravel} F300 G1 Z10 F6000 ; fine home in the -Z direction G90 ; absolute positioning G0 Y250 ; Move inside Y axis limits M564 H1 S1 ; Restrict axis movement to machine limits M104 S0Works great, thanks for the help and various ways that I could handle it. The M564 method seems to be the most robust way if I am going to run it as a macro.

-

@turtlecrawler Great, glad you got it working. However, I didn't know what a "Sex bolt style endstop" was, and was a little scared to Google! Eventually I did, and it's this: https://mods.vorondesign.com/details/t1DBVlcUBbdEK6habEsVzg

It's a nozzle touch off probe. You can see the top of it at the back of the bed, just to the left of the Z rail. Looks neat!Ian