Solution to delta printer falling arms and effector at power off

-

This is not specific to a Duet powered printer, but I thought I'd write about it here anyway.

TL;DR Stop your delta printer effector crashing into the bed at power off using this small part.

For a while I've been tinkering with a Tevo Little Monster that I "repowered" with a Duet Mini 5+ board. The printer uses a BL Touch for sensing bed height. What I have found is that when the printer was powered off, the effector and arms would sometimes start to slide down and hit the print surface with a thunk. This wasn't the end of the world, but when powering the printer back on the BL Touch performs a self test, and with the effector firmly on the print surface this self test fails. The upshot is having to turn the printer off again, raise the effector off the bed by hand, and, while holding it off the bed, reach up and power on the printer.

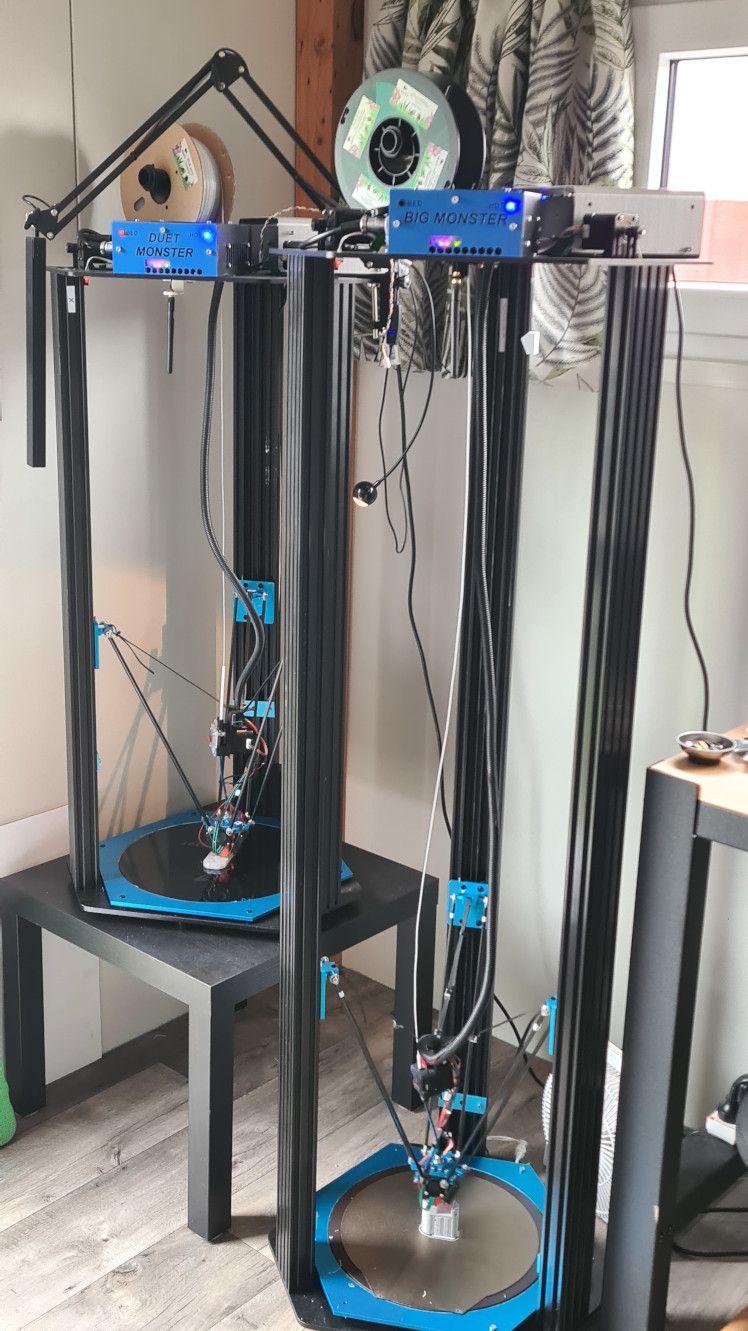

More recently I modded another Little Monster with another Duet Mini 5+ board, and gave it 1.5m rails instead of the 1m rails on the original. This printer has the same problem when the power is turned off, except now it's even harder to reach the power switch on the top of the machine without raising the effector a long way up. A hassle more than anything. Anyway I wondered about how I could fix this issue and here is my solution.

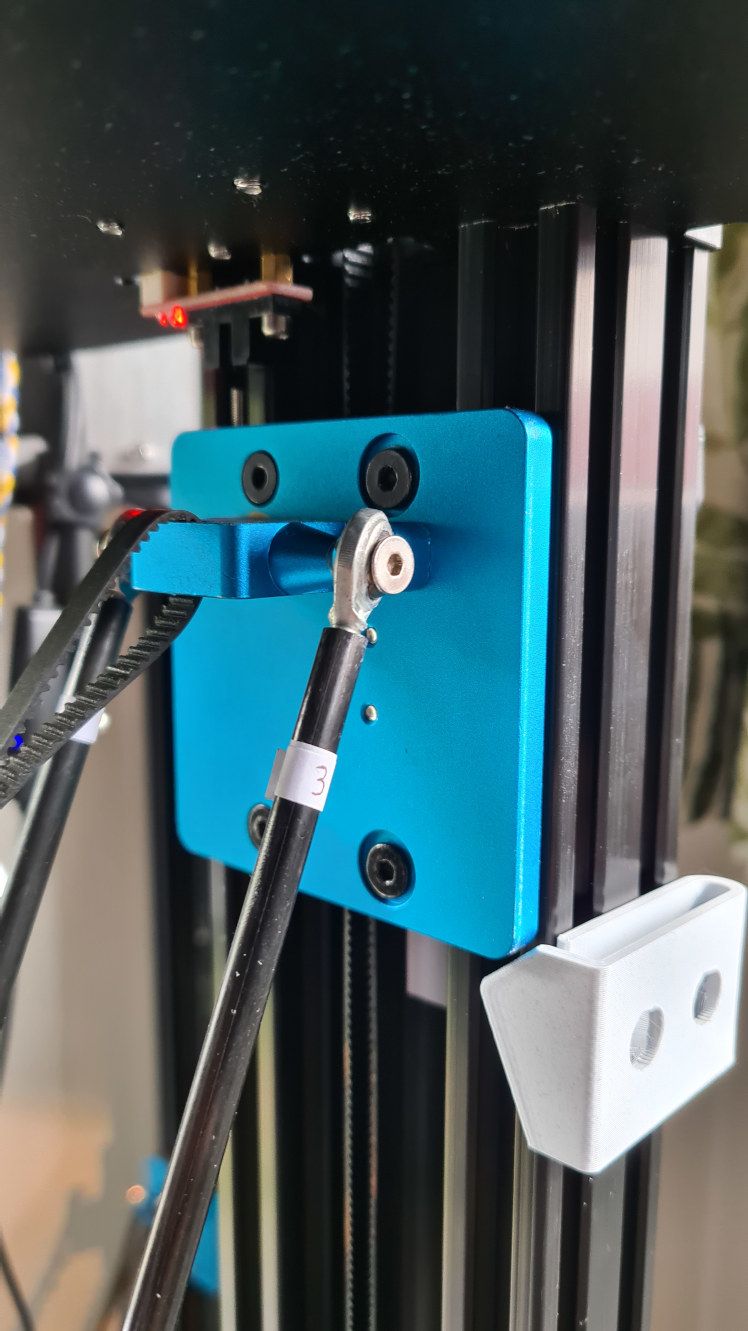

It's a flexible bracket that has enough resistance to stop the arms falling at power off, but not so much resistance as to stop the arms moving while under power. I position it a couple of mm below the rear carriage while the effector is in the parked position.

As these printers use 80x40mm C-beams the bracket I designed works with those only, however I think the idea could be applied to any other design. It's possible others have come up with something similar, but I didn't find anything in my searching. As is often the case the biggest problem may be figuring out what it's called!

Anyway, here are some photos. I use two screws with T-nuts to hold it on the rail.

Here is a photo of the two monsters, showing the bracket in place.

-

That's a cool mod. What do you use the big monster for, and how much print height do you get out of it?

-

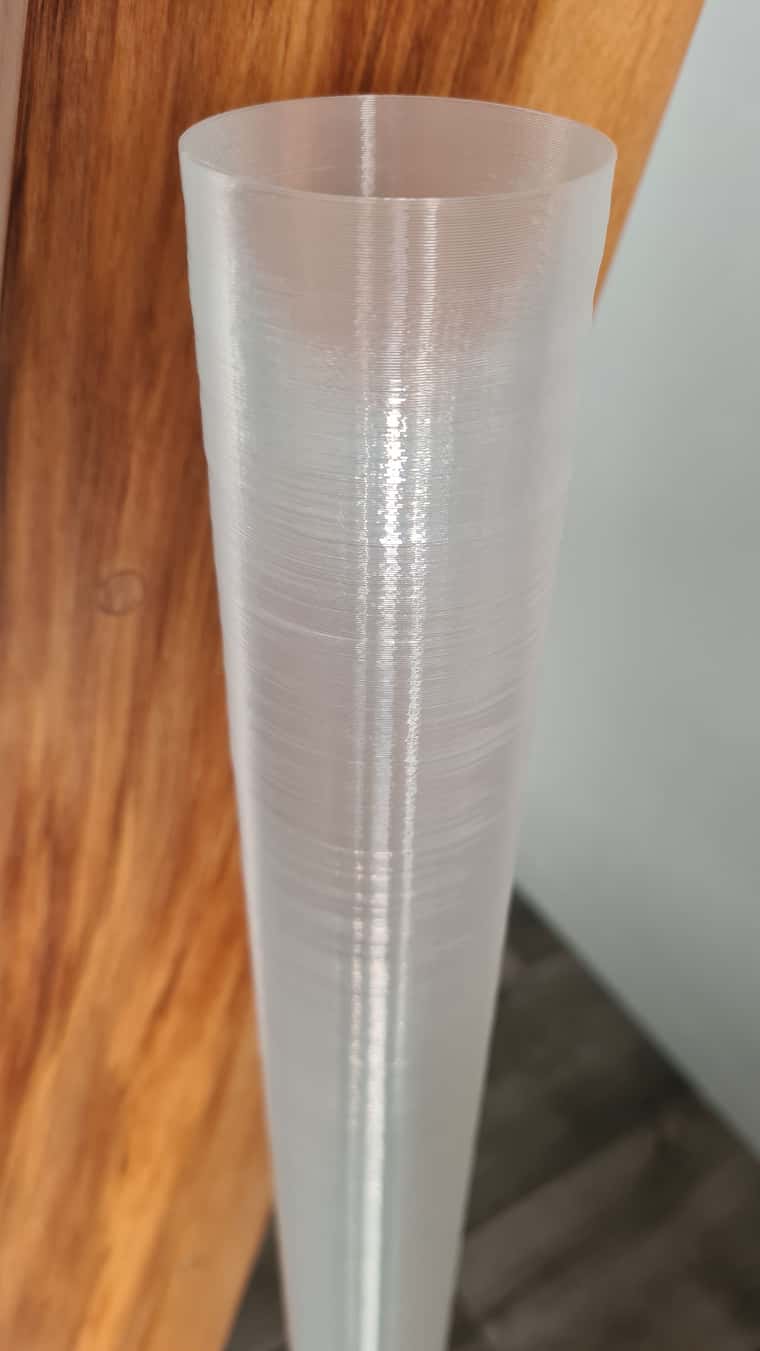

@moocowsia I'm still tuning it in, but I just recently printed a 50mm tube that's 950mm long. The delta printer is curious - the actual max height is just on 1000mm but the print volume is like a cylinder with a cone on top. If you want a flat topped anything it can't be the full height.

Here is the cylinder, on the right

Unfortunately I couldn't be there while it was printing and I think it wobbled a bit as the print got taller, so from about 300mm upwards it's got minor irregularities. This is printed on a PEI sheet with magnetic sheet stuck to the original little monster glass print plate.

The shorter print is from the shorter delta. It's only 400mm tall, but could have been a bit taller. This doesn't have any wobble, being shorter, and I think also because it was printed on a glass print surface with little flex. Curiously, the print quality of the shorter tube is better, but I forget the print settings - it may just have been printed more slowly.

The circular shape on this one looks more like many straight lines rather than a smooth circle. Not sure why; there are many differences from software (different versions of PrusaSlicer) through to lots of hardware differences (stepper motors).

I'm still thinking of neat things to print. Any ideas? LOL.

-

I've also got a Little Monster. I think they're fairly popular on here because a lot of people replaced the stock electronics on them.

They're very good at making large vases.

-

@martinv said in Solution to delta printer falling arms and effector at power off:

I'm still thinking of neat things to print. Any ideas?

My delta is my go-to printer. I print everything I need on it, except where I need the slightly wider (300x200mm instead of 300mm round) bed of my tool changer. I've recently been printing tools and jigs on it to aid with assembly of a light aircraft.