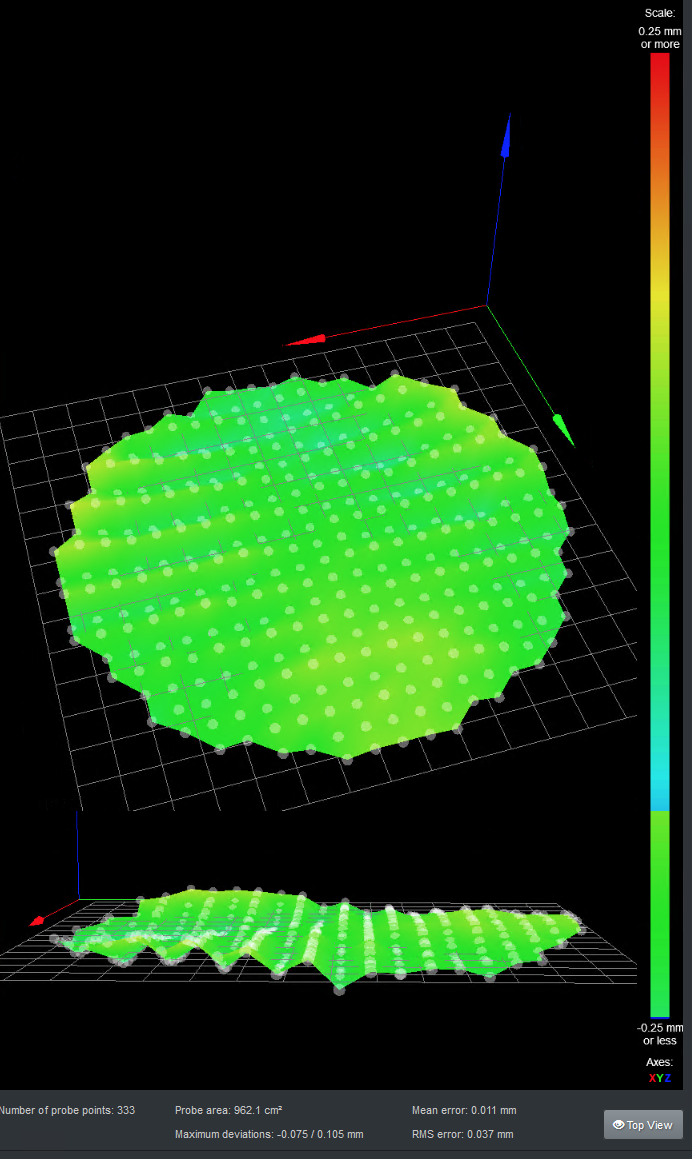

Wavy ridges in Mesh bed leveling on delta kossel xl

-

I've been trying to work out an issue with backlash on my kossel xl. I built it using DC42's guide, almost exactly. I understand the ridges relate to backlash but I can't seem to find it. Actually, I'm not sure which motor it is on based on the direction of the ridges.

The printer does a good job printing, I just have some backlash that's visible depending on what I print.

One of the stepper drivers on my duet wifi is bad. I switched to use the E2 stepper. Could this be related? It says there's a short to ground.

I put some more points on the auto calibration file. It calibrates at around 0.04. I've had it down to as low as 0.02, but the problem with backlash seems to be getting worse.

Things I've tried:

Lowering accel/jerk as much as possible.

Lowering speed and dive height on probe.

Checking the frame is square and level. Build plate is level as far as my micrometer can tell.

Lubricating magballs, carriers, linear rails

Removing zesty nimble entirely

Checking for loose magballsThings I've found:

The magballs need a lot of regular lubrication. Like every 24 hours of printing.

Linear rails need lubrication every month or so.

One of my rods is bent on the Z axis. When you rotate it on the magball, you can see the bend in it.

My steppers vibrate pretty bad at above 1.5a current. They never get hot. I just leave it at 1500ma.

I tried using steel core belts. I think it helped some but they were wearing out the pulleys so I switched back.Machine specs:

Followed DC42's large kossel guide

Duet wifi with smart effector

zesty nimble

Rubber gt2 belts, fiber reinforced from amazon

Optical endstops

1m linear rails with genuine hiwin carriages and duet3d pcb !magball mounts

Haydn's arms 480mm

400mm diameter bed on mic6 plate

16 tooth pulleys, smooth upper pulleys

moons 0.9 2.0a steppersFirmware Version: 2.02(RTOS) (2018-12-24b1)

WiFi Server Version: 1.21

Web Interface Version: 1.22.6Configs attached:

2_1553361419220_heightmap.csv

1_1553361419219_config.g

0_1553361419219_bed.g -

I had the same problem, and for me it was loose nuts on the effector/carriages.

-

They're all tight but I'm going to try some new rods and ball joints to see if that helps since one of the rods is bent.

-

I've seen small waves on the height map of my delta when the ball joints need lubricating, which I only do about every 6 months. But the printer is only lightly used.

Do the carriages run smoothly on the linear rails? What motors are you using, and what motor current have you set?

-

Well, I ordered new rods and balls from Haydn with 10mm tubes this time. Same problem. I also need to retune my radius as they are .1mm longer than the old set.

I've been using this lube:

White Lightning Clean Ride The Original Self-Cleaning Wax Bicycle Chain Lubricant, 8-Ounce Drip Squeeze Bottle

https://amzn.to/2JZUg9YThese are the motors, from Amazon:

MOONS' 0.9deg NEMA17 Stepper Motor 3D printer 2A 0.39Nm(55oz-in) 2Phase 39.8mm(1.57in.) High Accuracy Step Motor for CNC (Stepping Motor Cable00723 include, model MS17HA2P4200)

https://amzn.to/2I3dSXVCurrent is 1.5a. Anything more than that and I get a lot of vibration and noise from the motors. I'm beginning to think they may need replaced. I used the guide in the wiki to select them based on the recommended specs.

Specs are:

Parameter Unit Value

Phase 2

Step Angle 0.9°

Shaft Single

Frame Size NEMA17(42mm)

Length mm 39.8

Rated Current A 2

Holding Torque Nm 0.39

Holding Torque oz-in 55.23

Resistance Ohms ±10%@20℃ 1.05

Inductance mH Typ. 2.8

Coil Type Bi-Polar

Detent Torque mNm 16

Rotor Inertia gcm² 57

Front Shaft Length mm 24

Front Shaft Diameter mm 5

Terminal Number 4

Connect Plug

Insulation Class B(130°C)

Approvals RoHS

IP Rating IP40

Weight kg 0.29So, motors next?

-

@oarjjj said in Wavy ridges in Mesh bed leveling on delta kossel xl:

These are the motors, from Amazon:

MOONS' 0.9deg NEMA17 Stepper Motor 3D printer 2A 0.39Nm(55oz-in) 2Phase 39.8mm(1.57in.) High Accuracy Step Motor for CNC (Stepping Motor Cable00723 include, model MS17HA2P4200)

https://amzn.to/2I3dSXV

Current is 1.5a. Anything more than that and I get a lot of vibration and noise from the motors. I'm beginning to think they may need replaced. I used the guide in the wiki to select them based on the recommended specs.The motors sound good. Are you using 12V or 24V power? 0.9deg motors on a delta with 12V power will get noisy at higher speeds. The higher the current, the lower the speed at which they get noisy.

-

@dc42

24 volt PSU. Running at 1.5a I can generally run them as fast as possible. Somewhere around 300mm/s. You can't print that fast so I generally limit them to about 65mm/s.Anything above 1.5a, with a nozzle speed of higher than 40mm/s generates a lot of noise and vibration. The frame of the printer really rattles and if you feel the carriages, they're very notchy in their movement.

Normally the printer is essentially silent.

This is the 24v PSU I am using.

Cosel ADA1000F-24

https://octopart.com/ada1000f-24-cosel-82700There some voltage drop from the 400w heated bed so I adjusted it to be about 24.9v. I've tried to reduce the cable lengths as much as possible as well as double 16ga wire to the heatbed, and that's helped with the voltage drop considerably.

At 1.5a the motors have never heated up. Higher than that, although I've only done limited prints at like 1.8a (very noisy) doesn't make any heat either. I can heat up the extruder motor just fine though.

I usually run them at 1/16 with interpolation. They do run smoother at higher currents when using straight 1/64 microstepping.

Here's the mesh leveling with 2.0a current, 1/64 microstepping and 40mm/s max speed.

-

The crinkly effect where ridges parallel to the X axis at one end of Y turn into valleys at the other end indicates that you still have some backlash. Some possible causes:

- Lack of lubrication on the ball joints. I use a little silicone grease.

- Carriages too tight on the linear rails so that they stick when the belt reverses direction.

- Carriages too loose on the linear rails, so that they rotate a little when the belt reverses direction.

- Belts too loose.

- Loose pulleys (but that would probably cause a bigger problem then your height map shows).

You can measure the backlash of the system excluding the joints. Put a piece of paper under the nozzle and jog the effector down in units of 1 microstep until the nozzle just grips the paper. Then measure how many units you need to jog up again to release the paper.

You can also look at the carriage position under magnification, and use G1 S2 commands to see what is the smallest movement that you can command in the opposite direction to the previous motion that actually causes a movement.

HTH David

-

Some time has passed (new baby girl!) and I sat down with your advice to find the source of the problem. Moving the (genuine hiwin) carriages manually I found some binding in them at times.

Looking in to the problem I found that each of my carriages were missing 1 ball bearing. After adding the bearings, the problem has been completely solved.

My advice to anyone facing this problem is don't give up! and try practical tests like the ones David has mentioned. It's a frustrating experience but there is a solution!

Thanks again dc42!