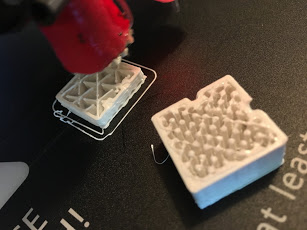

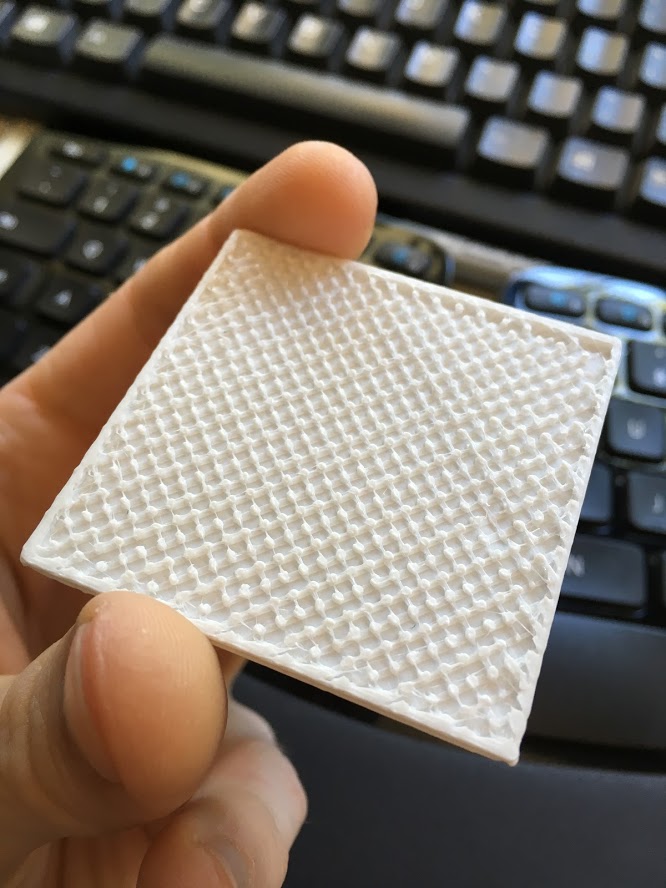

Infill lines not connecting

-

I can’t figure out what’s going on with this machine I just finished building. I’m embarrassed to have to ask for help but I’ve done everything I can think and still I’m having really strange issues.

I’m using a triangle labs bondtech extruder. I’ve calibrated it and check to make sure xyz all travel the amount they should.; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2 on Mon Jun 17 2019 09:34:44 GMT-0700 (Pacific Daylight Time); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves; Network

M550 P"Model 3" ; Set machine name

M552 S1 ; Enable network

;*** Access point is configured manually via M587

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S1 ; Physical drive 0 goes forwards

M569 P2 S1 ; Physical drive 2 goes forwards

M569 P1 S1 ; Physical drive 1 goes forwards

M569 P3 S0 ; Physical drive 3 goes forwards

M569 P4 S0 ; Physical drive 4 goes forwards

M584 X0 Y2 Z1 E4 ; Apply custom drive mapping

M350 X32 Y32 I1 ; Configure microstepping with interpolation

M350 Z8 E16:16 I1 ; Configure microstepping with interpolation

M92 X160 Y160 Z2723.7354 E413:413 ; Set steps per mm

M566 X4000 Y2000 Z60 E2500:270.00 ; Set maximum instantaneous speed changes (mm/min)

M203 X27000 Y20000 Z350 E3600:3600 ; Set maximum speeds (mm/min)

M201 X1500.00 Y1500 Z60 E3000:3000 ; Set accelerations (mm/s^2)

M906 X1000.00 Y1400 Z1100 E1560 I35 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; Set axis minima

M208 X450 Y295 Z430 S0 ; Set axis maxima; Endstops

M574 X1 Y2 S1 ; Set active high endstops; Z-Probe

M574 Z2 S2 ; Set endstops controlled by probe

M307 H3 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch

M558 P9 H5 F100 T2000 ; Set Z probe type to bltouch and the dive height + speeds

G31 P25 X27.72 Y-25 Z1.7 ; Set Z probe trigger value, offset and trigger height

M557 X0:450 Y5:295 S50 ; Define mesh grid

M671 X14:14:450:450 Y285:25:25:295 S1.0 P0.5 F1.0; Heaters

M307 H0 B0 S1.00 ; Disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4138 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4092 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S270 ; Set temperature limit for heater 1 to 300C; Fans

M106 P0 S0 I0 F500 H T45 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

-

Layers may be too thin or hotend not hot enough are two causes I've had.

-

0.2mm layer height 0.4mm nozzle default cura settings

-

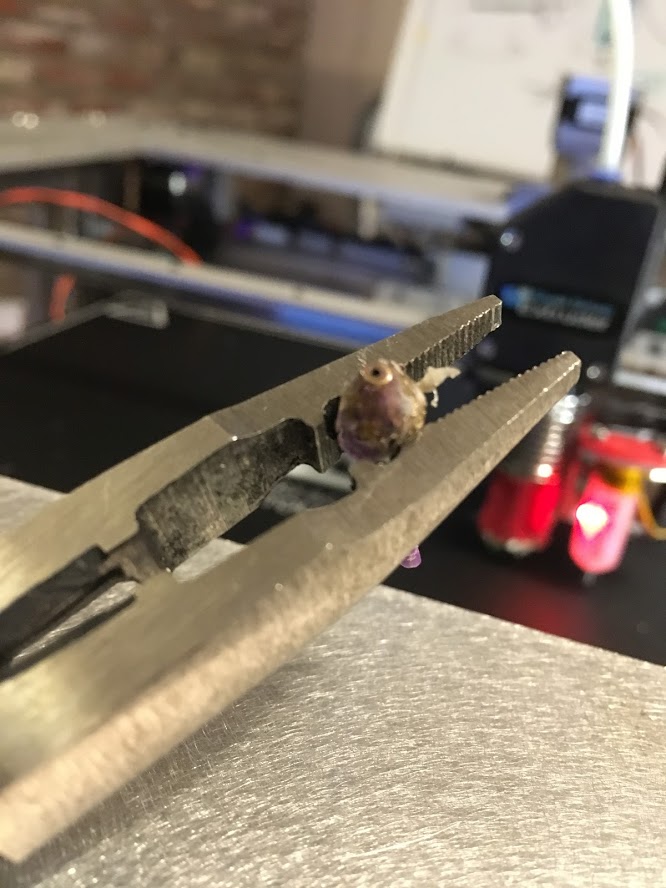

Well.... unbenounced to me I was using a 0.75mm nozzle.. which explains a lot. Just wish I had caught this mistake yesterday or now that I think of it a few months ago when I was having the same exact problem in another printer that I was using this nozzle in. now my print quality is great. Live and learn lol