Motor settings (Drives) ?

-

Hello,

I am trying to determine and understand how I can accurately calculate the values of my engines for M350. M566. M203. M201. M906.

Motors X / Y / Z(x2):

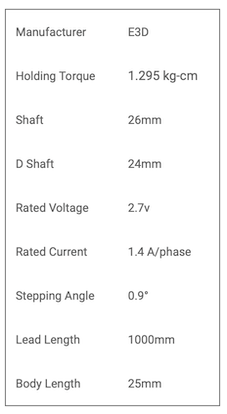

Extruder Motor:

CoreXY type

12vCan you help me, thanks

-

for m350 use x16 microstepping with interpolation.

motor current should be 70-80% of the max current.the rest of the parameter depend on your printer.

start of with the default parameter from the configurator.

then print a test print. increase the values and print the same again and compare the result. -

Thank you for the answer,

However, if I take 70% of the mA of my motor (E) it gives me as value: 1400mA x (70/100) = 980.

If I put my value found in M906 my extruder makes noise blocking. In addition, if I want to make a G1 E100 I have to put a maximum speed of F1 otherwise my extruder does not extrude the long requested.

Either my calculation is not good ... or I have to adjust something else too.

Here my parameters.

-

The extruder will not be able to extrude at 2000mm/min, but at 600mm/min it should.

Feedrates of 2000mm/min are used for retractions.Also the M906 values are rounded down to 100mA on Duet2 and down to 50mA on Maestro. So use M906 E1000.

-

@rudy2a said in Motor settings (Drives) ?:

if I want to make a G1 E100

do the extrusion from the DWC page. There you can select the speed.

-

Thank you for that, it's OK: M906 E1000.

I have a problem on the Z. If I mount M203 Z200 to more than 200, my screws or my Z (double Z) motors make an impossible noise ...

An expert would be kind enough to analyze my files below and tell me if there is an anomaly on speeds, intensity (mA), or any other ...

A big thank-you...

-

a 2mm lead screw wont be able to do 200mm/min with 12v. so reduce the max speed

-

@veti said in Motor settings (Drives) ?:

une vis mère de 2mm ne pourra pas faire 200mm / min avec 12v. alors réduisez la vitesse maximale

Thank you for this valuable information, which makes me understand a little more about my configuration ...

I would like to understand what value is recommended. A formula exists to calculate the maximum speed of a screw (2 mm) under a 12V supply.

Because I guess I can not put a value at random? Between 1 and 199, the Delta is big!

I'm sorry, I only start with DUET ...

-

do a binary approach.

halv it. ie. 100.

if it works increase by half i.e 150 then either 175 or 125 etc.

if not go 50 then either 75 or 25 -

Fast, accurate ... thanks for your answers!