Warning for motor phase on RRF3b12

-

I finally attached my extruder motors to duet2eth and I'm getting these warnings

11/11/2019, 2:08:24 AM: T0 11/11/2019, 2:08:32 AM: G1 E0 11/11/2019, 2:08:46 AM: G1 E10 11/11/2019, 2:08:53 AM: G1 E100 11/11/2019, 2:08:54 AM: : Warning: motor phase A may be disconnected reported by driver(s) 3 Warning: motor phase B may be disconnected reported by driver(s) 3 11/11/2019, 2:09:05 AM: T1 11/11/2019, 2:09:11 AM: G1E100 11/11/2019, 2:09:12 AM: : Warning: motor phase A may be disconnected reported by driver(s) 4 Warning: motor phase B may be disconnected reported by driver(s) 4Motors are 1.2A nema 17, possibly with high inductance (will measure tomorrow) but since they need to drive 40:1 flex3drive I dropped the current to 800mA as it is more than enough. They properly rotate but I get this warning. Motors are DPM42SH47-1AM.001 (0.9degree step angle 1.2A 3.17kg*cm)

M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S0 ; physical drive 1 goes backwards M569 P2 S0 ; physical drive 2 goes backwards M569 P3 S1 ; physical drive 3 goes forwards M569 P4 S1 ; physical drive 4 goes forwards M584 X0 Y1 Z2 E3:4 ; set drive mapping M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E4074.37:4074.37 ; set steps per mm M566 X900.00 Y900.00 Z120.00 E150.00:150.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z1200.00 E1200.00:1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E250.00:250.00 ; set accelerations (mm/s^2) M906 X1000 Y1000 Z1200 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeoutthe steps/mm for the extruders are not calibrated yet (that's some random value there) but I doubt that's a problem. cables are tested good, motors rotate smoothly and I don't see any move errors reported just this warning...

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.0beta12 running on Duet Ethernet 1.02 or later ... === Move === Hiccups: 0, FreeDm: 169, MinFreeDm: 168, MaxWait: 57799ms Bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves: 3, completed moves: 3, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 === AuxDDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0how is this warning "detected" ? overloaded motors? underloaded motors?

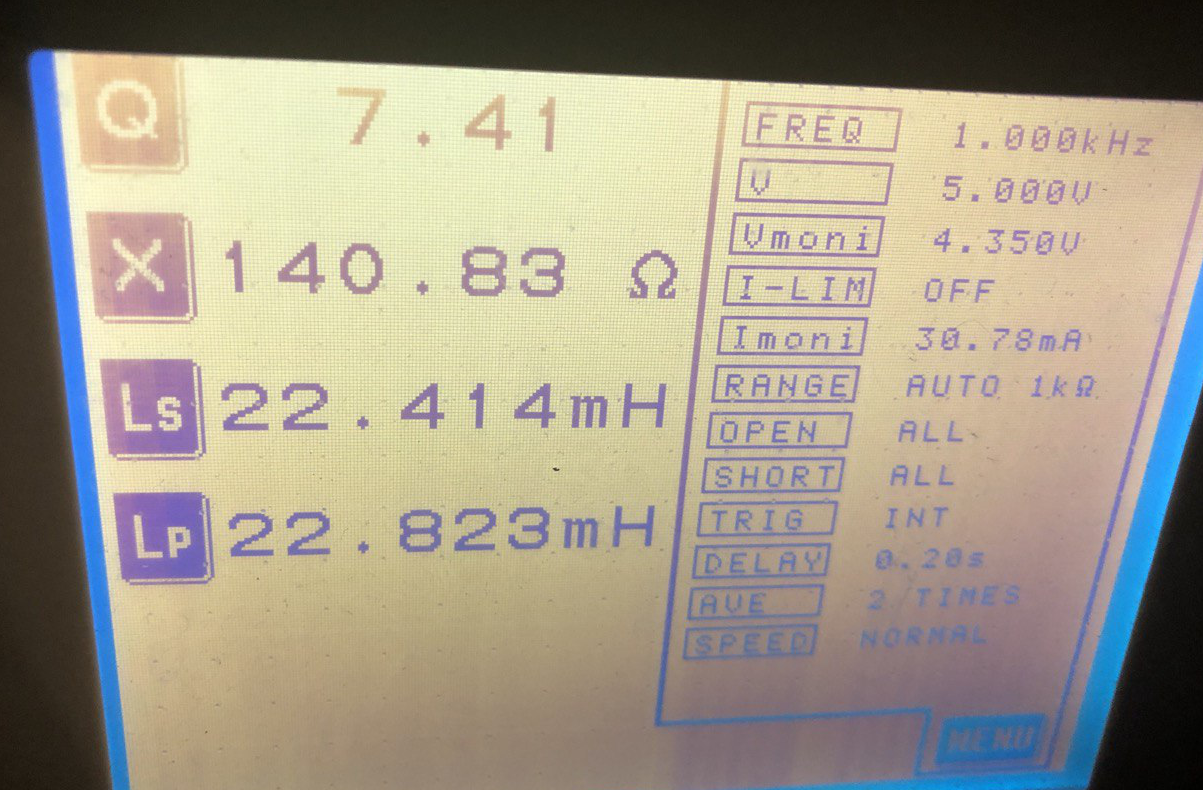

I'm measuring 7R36 for each coil..

If I connect a puny pancace motor (2R per coil) I don't get no warnings for it ..

any hints?

p.s. I tried to up the current for both E motors to 1A2 as they are rated but nothing changed

M906 X1000 Y1000 Z1200 E1200:1200 I30also when I move at speeds over 500 I have this problem so

G1E30F600 -> warning (around 400rpm)and for speeds below 500

G1E30F400 -> no warning (around 250rpm)

G1E30F300 -> no warningnow these speeds are unusably slow but... (talking about RPM, the steps/mm is not yet configured as I said)

p.p.s. I do not have thermistors on e0/e1 yet so I'm showing -273 as expected but Im using M302 P1 to allow moving that ignores temperature

-

@smece said in Warning for motor phase on RRF3b12:

I finally attached my extruder motors to duet2eth and I'm getting these warnings

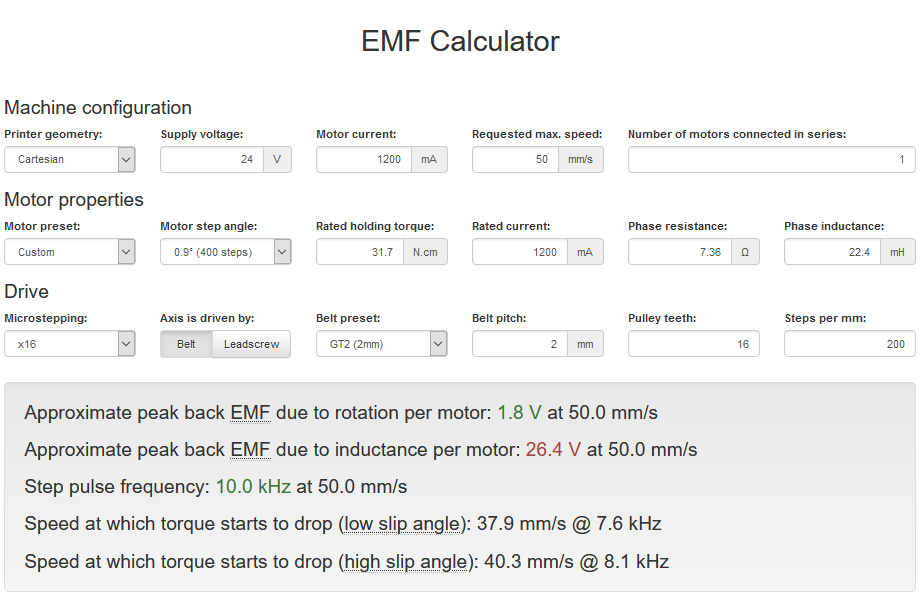

What I suspect is happening is that you are driving the extruder motor too fast for the inductance of the motor and the VIN supply voltage you are using. I suggest you take the data for that stepper motor at http://www.minimotors.eu/attachment.php?id_attachment=27 and plug the figures into the EMF calculator at https://www.reprapfirmware.org/ to see what will be the maximum speed before you start to lose torque.

G1E30F400 -> no warning (around 250rpm)

G1E30F300 -> no warning

now these speeds are unusably slow but... (talking about RPM, the steps/mm is not yet configured as I said)Those speeds (250rpm, more than 4 revs/sec) are quite high. Your E steps/mm is very high. If the correct steps/mm for your extruder falls in the mores usual range, the corresponding extrusion feed rates will be higher.

-

looks like this motor/driver/speed configuration is not going to cut it so I'll go with other motors... no need for .9 degree with 40:1 gear ration anyhow

btw, what are the motors measuring? slipping or ? when they are complaining

-

M92 X80.00 Y80.00 Z400.00 E8321.95:8321.96uh, 3.5mm/sec is kinda as fast as this will go .. more and I get these warnings and already below 10mm/sec motor stalls

... need to use some other motors or remove microstepping .. I went with 16 with interpolation, dunno how will this work since motors are sharing config?!

... need to use some other motors or remove microstepping .. I went with 16 with interpolation, dunno how will this work since motors are sharing config?!M350 X16 Y16 Z16 E1:1 I1what can I expect here? XYZ using interpolation 1/16 microstepping and E0/E1 not using microstepping nor interpolation or none will use interpolation or XYZ will use interpolation and E0/E1 will ?! (it's still too fast for this motor but sound is weird so just interested if it's using interpolation or not)

-

The

I1will only apply to the drives that are at 16. If you do anM350after your command you should see...M350 Microstepping - X:16(on), Y:16(on), Z:16(on), E:1 -

@smece said in Warning for motor phase on RRF3b12:

M92 X80.00 Y80.00 Z400.00 E8321.95:8321.96uh, 3.5mm/sec is kinda as fast as this will go .. more and I get these warnings and already below 10mm/sec motor stalls

... need to use some other motors or remove microstepping .. I went with 16 with interpolation, dunno how will this work since motors are sharing config?!

... need to use some other motors or remove microstepping .. I went with 16 with interpolation, dunno how will this work since motors are sharing config?!Your E steps/mm is vert high (I presume you are using a remote direct drive extruder), so the motor needs to turn very fast to achieve good extrusion speeds. To achieve that, you need a low inductance 1.8deg motor and 24V power.

The open load detection kicks in when there have been no chopper events the driver for a certain period of time. This happens when the driver can't achieve the required current even by applying VIN to the motor output terminals. This will occur if either the motor phase is disconnected, or if the combined rotational and inductive back emf exceeds the supply voltage. This in turn means that you don't achieve the usual torque for the current you have set, and the motor becomes noisy because the current in it is no longer sinusoidal.

If you reduce the motor current, the inductive back EMF will fall in proportion, which will delay this happening until a higher speed. But the back emf due to rotation doesn't change with current, so you will still reach a limit.

-

@dc42 said in Warning for motor phase on RRF3b12:

Your E steps/mm is vert high (I presume you are using a remote direct drive extruder),

Yes, 40:1 gear ratio dual flex3drive

so the motor needs to turn very fast to achieve good extrusion speeds. To achieve that, you need a low inductance 1.8deg motor and 24V power.

I am on 24V that part is not a problem but still 0.9 motor will not cut it, especially not high inductance like this one .. problem is I have bunch of these 0.9degree motors and 100+ different nema23 motors and almost none 17's that are not 0.9.. any more .. I ordered some nema8 and will try these few 17's I have

The open load detection kicks in when there have been no chopper events the driver for a certain period of time. This happens when the driver can't achieve the required current even by applying VIN to the motor output terminals.

ah, clear, great way to detect failure, if you can't push enough current either emf is fighting you or motor is not connected

... genious

... genious

If you reduce the motor current, the inductive back EMF will fall in proportion, which will delay this happening until a higher speed. But the back emf due to rotation doesn't change with current, so you will still reach a limit.

all clear, now while I don't need a lot of torque the problem is that at still very low speeds motors stalls completely so I have to switch ... these 0.9 degree ones I purchased for XYZ 1605 ball bearing screws so looks like that's all they are going to be good for

Thanks a bunch for clarification!!